Origins

The Bell 47B was the first helicopter specifically developed by the Bell Aircraft Corporation for civil use. It was the result of the experiences gained by the "Gardenville group" headed by Arthur M. Young (1905-1995), a rotary-wing pioneer (but also a cosmologist, philosopher, astrologer and writer) who worked on the three Bell Model 30 prototypes between 1942 and 1945.

In 1928 Young set up a small laboratory in a barn on the family estate in Radnor (PA) where he began experimenting with small electric models.

After 13 years of research and many failures Young understood that the stability of a two-blade rotor could be significantly increased thanks to a stabilizer bar with counterweights to both extremities mounted perpendicularly to the two blades and linked directly to the rotor so the rotor plane was controlled independently of the mast. This device significantly enhanced the stability.

In September 1941 Young packed one of his models along with some films and went to Buffalo (NY) where he met some Bell's engineers. There he presented his films and did some test flights inside a hangar with his remote-controlled model.

In that occasion he met Lawrance (Larry) D. Bell (the founder of the Bell Aircraft Corporation in 1935). The two of them made a deal for the development of a full scale helicopter and therefore in June 1942 Young and his assistant Bart Kelley moved to Gardenville, a hamlet on the north border of West Seneca, New York, where along with a small team he could work in relative secrecy. The first test flight of the prototype known as the Model 30 occurred in July 1943.

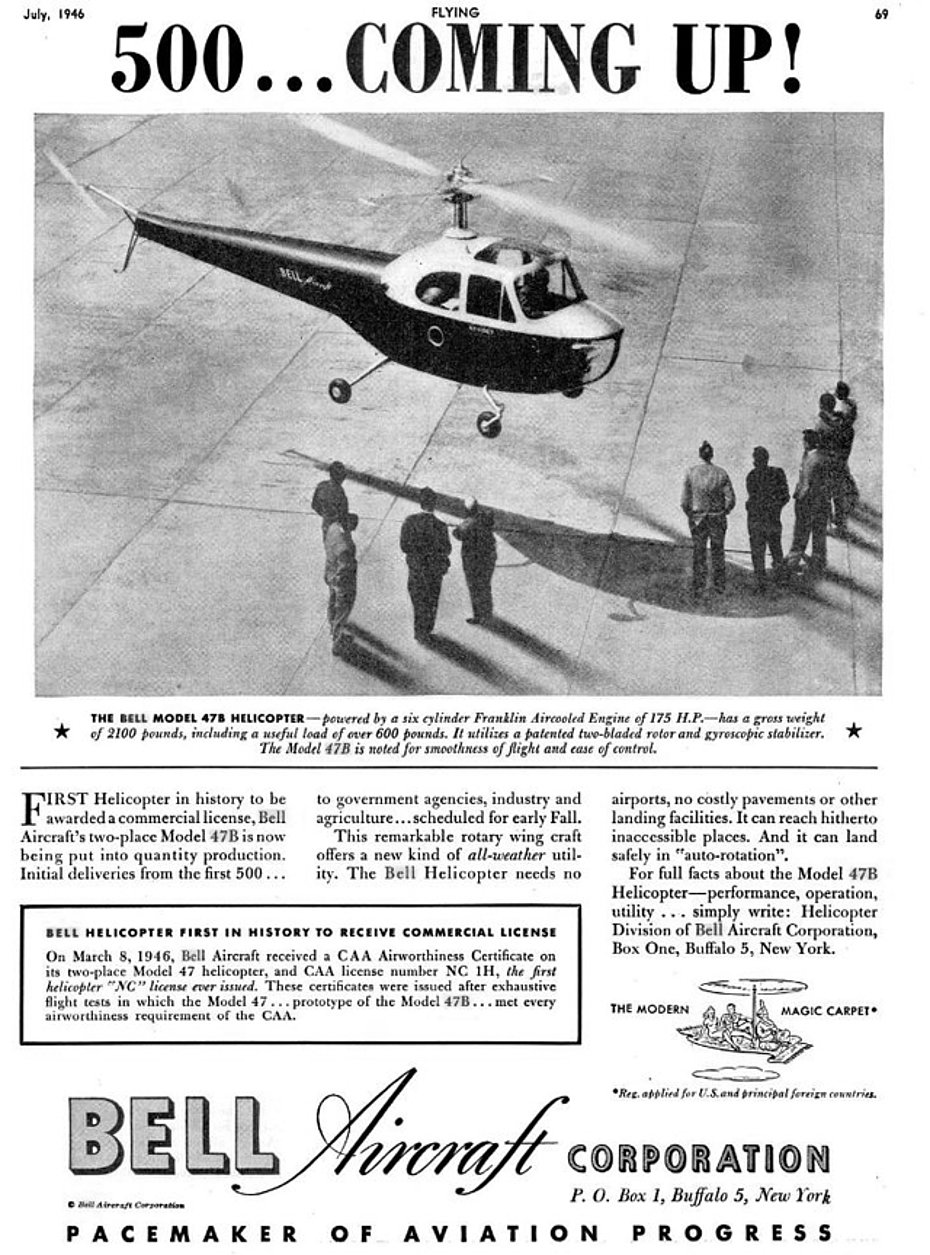

On March 8, 1946 the Model 47 was awarded the world’s first commercial helicopter license. Exactly two months later on May 8, 1946 Bell received helicopter type certificate no. 1 (NC-1H) from the CAA.

It is interesting to remember that in the various versions (over twenty were developed by the American manufacturer) the Bell 47 was built in more than 5,000 units by Bell to which are added over 1,400 units produced under license in Italy, Japan and England.

The assembly line of the Bell 47 has been active for 27 years. In fact production ceased in 1973.

Automotive design

From an aesthetic point of view the Bell 47B looks very different from the other Bell 47 models produced later. The Bell 47B featured car-like windscreen discarded on later variants and replaced be the famous fish-bowl cockpit bubble which made the Bell 47 one of the most popular helicopter in the world.

At that time many people were convinced that the helicopter would eventually replace the car, and it should not be surprising that Larry Bell himself asked a Detroit car manufacturer to assist his engineers in the styling of the helicopter.

Legend has it that Larry Bell wanted the Model 47 to appeal to non-pilots and required a cabin configuration with doors large enough and cabin high enough to enable a gentleman to get in without having to remove his hat. Even a top hat.

It should also not surprise that the helicopter was equipped with ashtrays, glove box, soundproofing, two upholstered seats arranged side by side and fitted with safety belts, carpets and a generous luggage compartment. Like in a car the windows in the doors could easily be opened or closed to control ventilation.

In 1946 Bell built two prototypes of the Bell 47B (NX41967 s/n 2 and NX92845 s/n 9) and in the course of the year in a huge hangar of the Bell plant on the airport of Niagara Falls in Wheatfield (state of New York) the assembly line was set up for the production in series of this model which took place in parallel with that of the 28 Bell 47A (military designation YR-13 / HTL-1) ordered by the US Army Air Force.

Unfortunately at that time whilst the pre-series models were tested some dramatic flight incidents occurred.

The first took place on August 10, 1946 near Lakewook NY when Milton R. Carlson, the brother of Floyd Carlson who had been the first professional test pilot hired by Bell for the helicopter program and among the first helicopter pilots in the US, lost his life.

The cause of the accident was never ascertained and this dampened the atmosphere of general enthusiasm that was growing around the new invention.

But what’s a helicopter for?

In an advertisement appeared on the aviation magazine Flying in June 1946, Bell stated that that year a production of 500 helicopters was scheduled. It was in fact estimated that there would be a strong demand from government agencies, industry, commerce and agriculture.

For this reason Bell bought 500 Franklin engines most of which ended up as we will see to accumulate dust in a warehouse.

The problem at the time was that, except for insiders, few people really knew what a helicopter was capable of. Therefore it was necessary to show the potential of this aircraft whose transport capacity and performance were still, it must me said, rather limited. For this reason some pilots were charged to carry out promotional tours.

But the problems were certainly not yet over. One obstacle that surely restrained sales of the helicopter was its price of $ 25,000, which was three times more expensive than that of a light aircraft and ten times the cost of a luxury car.

According to an internal report the standard cost of a Bell 47 helicopter was $ 21,771. This was broken down into labor and overhead: $ 12,000; material $ 5,600; production tooling $ 1,953; engineering $ 2,218.

Sales of the new Bell helicopter were much less than what Larry Bell and management had envisioned.

Despite the quickly accumulated record of utility, the company’s investment was returned slowly.

Based on the information gathered between 1947 and 1950 (i.e. before the outbreak of the Korean War) Bell sold only something like 175 helicopters, few if we consider that in less than five years between the start of the program in 1941 and certification the company had invested more than one million man hours, 4,000 hours of flight testing, and almost $ 5 million in the helicopter program.

Another obstacle that somehow restrained the enthusiasm was the fact that the early models required plenty of maintenance. Grease nipples and grease boots were still in the future, so the helicopter had to be taken apart after every 25 flying hours to be lubricated. The transmission had to be taken apart too, and have bearings replaced and hand-packed with grease every 25 hours. The maintenance engineer had his hands full. The old brochures never mentioned this fact because it would potentially have deterred potential customers.

Fortunately overhaul intervals on the helicopter went from 25 hours to 50 hours and then to 100 and finally to 200 hours before having to tear down the aircraft. This resulted in the helicopters being able to be away from their main base for longer periods before requiring major down-time for overhauls.

On request Bell organized a mobile workshop (Bell Aircraft Helicopters Mobile Service Unit) which went directly on site with the spare parts needed in order to do the maintenance work and the repairs.

First deliveries

Despite the difficulties already mentioned (and of course many others) the American manufacturer started to deliver the first commercial helicopters.

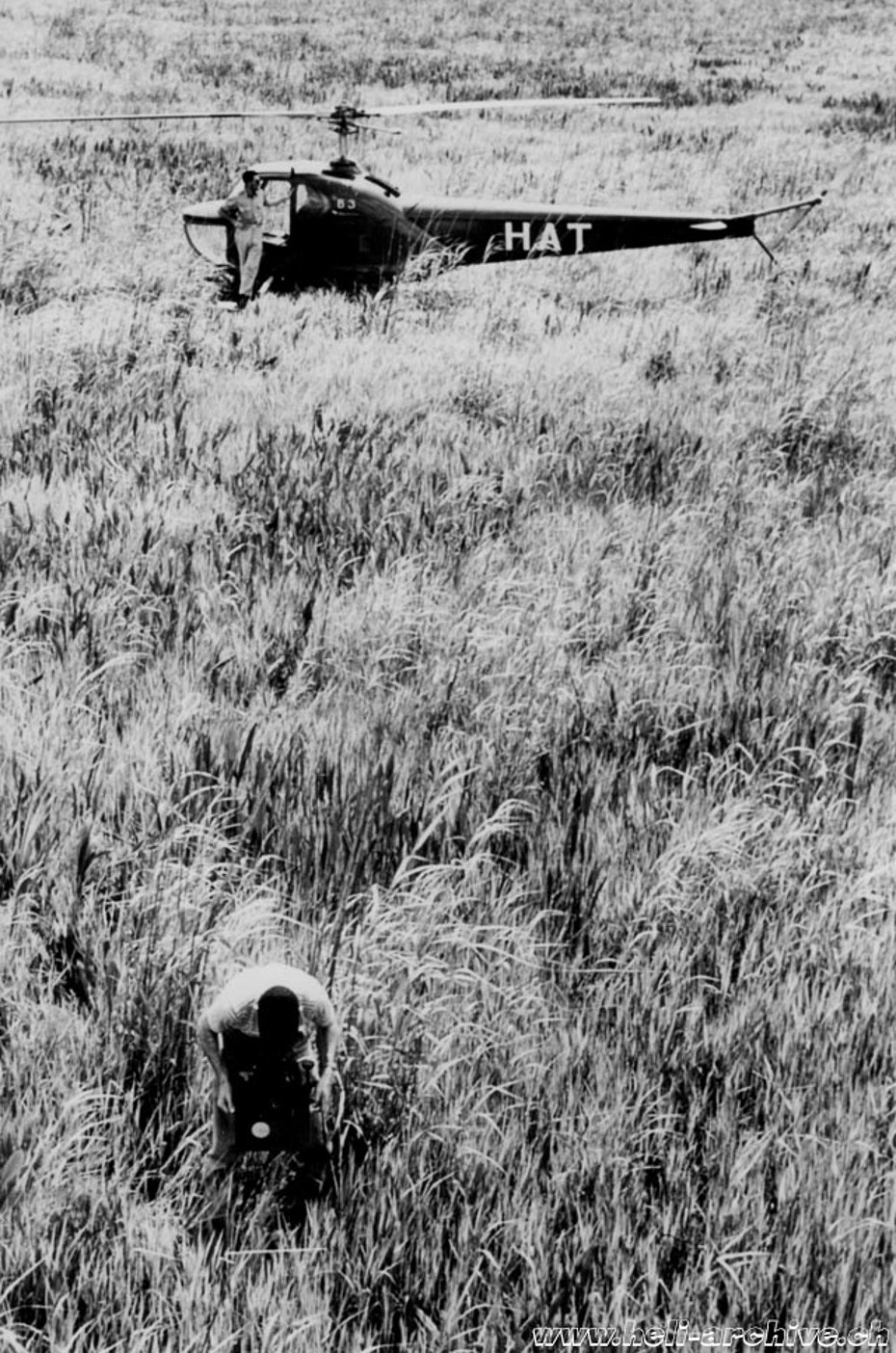

The first Bell 47B registered NC7H was delivered on December 31, 1946 to Helicopter Air Transport (or HAT as it was known) based at the Central Airport in Camden New Jersey, the first commercial operators of helicopters in the world.

Unfortunately shortly after the first deliveries a serious technical problem due to a leaking oil seal on top of the transmission forced Bell to ground 27 aircraft. The source of the problem was quickly determined.

During this difficult period unfortunately several incidents occured (namely 19 between 1 January 1947 and 31 August 1948), forcing the manufacturer once again to ground all Bell 47B (and the 47B3 version developed specifically for agricultural use) for safety reasons in order to ascertain the causes.

Investigations revealed that the incidents were due to pilot errors (lack of flight experience), inadequate maintenance, but also to technical defects of the aircraft.

First commercial employs

On 5 January 1947, HAT commenced a high-priority freight service on behalf of the magazine Filene’s in Boston (Massachusetts). However this job did not last long: the helicopter was simply too expansive. An hour of flight usually cost around $ 75, a lot of money at that time!

The Bell 47Bs were used for various aerial services which then became a classic for the rotary-wing such as for example flying school, power or pipeline patrols, or aerial photography.

New types of work for the helicopter were on-going, in field such as agriculture, forestry, or oil and gas exploration.

Curiously the first really profitable job for HAT’s helicopters was of a different kind: like the animals of the zoo the helicopter was often used to attract crowds of onlookers to public events. There was a great curiosity around the egg-beaters, but again this business did not last long and therefore both HAT and the other commercial helicopter operators (among the first we could mention Lundberg Ryan, Southern Arizona Air Service, New England Helicopter Service, Central Aircraft, Helicopter Field Operation, Armstrong Flint) were forced to find new job opportunities.

In July 1947 one of HAT’s Bell 47B on floats was sent to Louisiana to be used on behalf of the Robert H. Ray company Houston, a geophysical company conducting gravimetric oil surveys in a marshy area near Houma. For environmental reasons the use of special vehicles known as marsh buggies was not allowed in that area, and therefore it was decided to employ experimentally the helicopter. Its use proved to be much more convenient, faster and especially more economical. The Bell 47B moved from point to point a technician with a gravimeter.

From that moment on the petroleum industry commenced to increasingly use helicopters for tasks of all kinds.

As regards to the flight school HAT proposed three types of courses. The first included 20 hours of instruction on Sikorsky S-51 (this helicopter was the second in the United States to be granted a CAA type certificate) and was intended for pilots with at least 500 hours of flight time on airplanes (cost $ 2,000). The second on the Bell 47B intended for pilots with at least 200 hours of flight experience that included 25 hours of flight, and the full course that included five hours on the Bell 47B and 20 hours on the Sikorsky S-51 (cost $ 2,300). The helicopter school was very expansive if we consider that the annual pay of a mechanic was $ 3,500, and that of a mechanic’s assistant $ 2,300.

Despite the success of the operation in Louisiana on October 21, 1947 HAT filed a petition for permission to reorganize under the bankruptcy act in the District Court of New York. The judge permitted HAT 30 days to show its reorganization plans, however it was simply too late to avoid bankruptcy.

The same happened to many other operators, speculators and visionaries who courageously (and perhaps too much optimism) decided to invest their money in this new sector of civil aviation.

European deliveries

In Europe the first Bell 47B (SE-ATZ) was delivered to Lennerd Osterman founder of Osterman Aero AB, the world's first commercial helicopter company outside the USA. The helicopter was shipped to Sweden on January 9, 1947 and made the first flight on 20 February.

Among the first European operators there was also Irvin-Bell Helicopter Sales Ltd. a company established in August 1947 as the result of a partnership between Leslie Irvin (founder of the Irvin Air Chute Company), Scottish Aviation and Bell Aircraft Corporation.

The company, based at Prestwick airport, purchased Bell 47B G-AKCX (s/n 49) to explore potential applications of the helicopter. In addition to promoting sales it wanted to open a school for pilots and mechanics, perform spray flights, search and rescue missions, aerial inspections, aerial photography, mail transport, road traffic control and taxi services.

On September 25, 1947 this helicopter became the first commercial helicopter to cross the English Channel. Demonstrations were made in Belgium, Holland and Switzerland.

A few days earlier in a document dated September 22, 1947 Larry Bell stated that the fleet of Bell 47B (and 47B3) had accumulated around 8,000 flight hours during the first nine months of operation.

The successors

Meanwhile the production of the Bell 47B had already been suspended. The last (s/n 50) assembled (NC130B) was delivered on June 16, 1947 to Gannett Newspaper Rochester N.Y.

From the experience accumulated on this model (and the agricultural version known by the designation Bell 47B3) Bell developed a new helicopter known as Bell 47D.

Altogether 43 Bell 47B were produced. Several of these were successively modified and upgraded to newer versions that radically changed their original look and this in order to be adapted to the needs of their operators.

The last Bell 47B airworthy was N116B restored in 1989 by a private owner and today displayed at the National Air and Space Museum.

Another historical helicopter nowadays preserved is N5C (s/n 3) originally used as a Bell demonstrator until it was sold to Chicago Seaplane Base in April 1951 where it was used for student training and charter work.

In February 1958 it was sold to Dr. Carrol Voss, pilot, entomologist, and founder of Agrotors Inc., in Gettysburg, Pennsylvania who modified the aircraft and used it in agricultural applications for many years before restoring it to its original configuration in 1982. In November 1996 Dr. Voss donated the helicopter to the American Helicopter Museum based in West Chester (Pennsylvania).

Despite the fact that it has been manufactured in a limited series, the Bell 47B has a great merit: it signed the birth of the helicopter industry.

Technical description

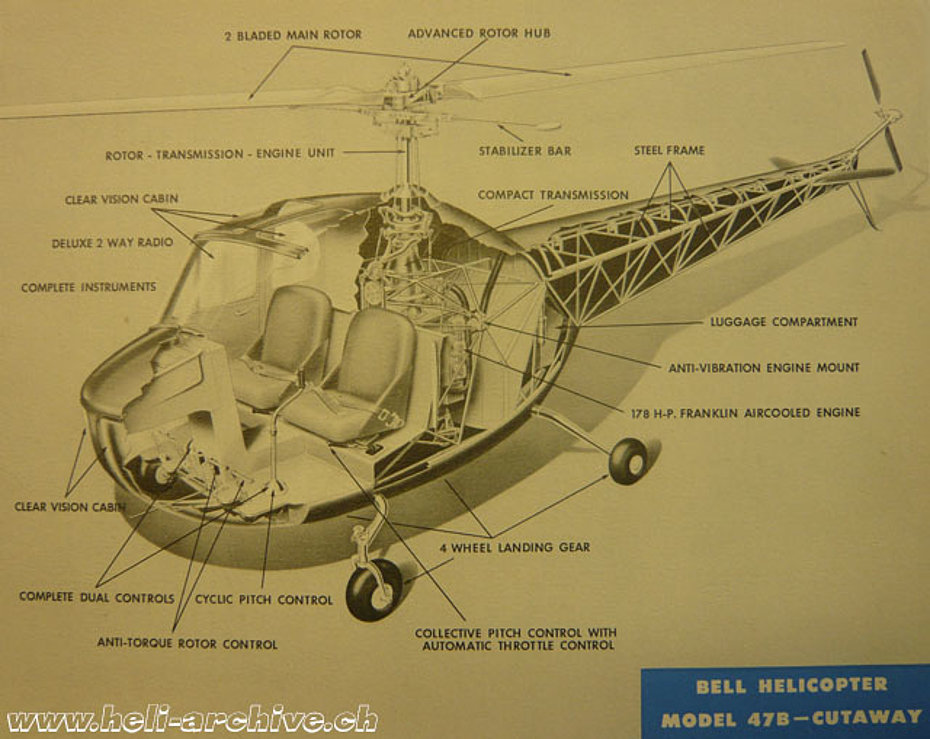

The Bell 47B is a helicopter of standard configuration with a two-blade main rotor and an anti-torque tail rotor.

The main rotor is equipped with the famous stabilizing bar. The main rotor blades, of symmetrical aerofoil section, are made of laminated wood with a steel insert in the leading edge for strenght and mass-balance.

The fuselage is built in three sections: the cabin, the center frame with the engine and its accessories and the tailboom.

The cabin witdh is 4ft 3’ (128 cm) and accomodates a passenger next to the pilot. Access to the cabin is possible through a large detachable door on each side.

All instruments, engine controls and switches are placed on a central column and are readily accessible.

Thanks to a generous area of Plexiglas visibility is generally good in all directions, but not as good as in the models fitted with the iconic fish-bowl cabin. Electrical installation includes: starter, generator, ammeter, 12V battery, navigation lights, instrument panel light, radio and auxiliary fuel pump.

The center section accomodates the six cylinders opposed air-cooled motor type Franklin 6V4-178-B3 5,489 ccm (335 cubic inches) which has a maximum take-off power at sea level of 130/178 kW/hp @ 3'000 rpm.

The engine with clutch, drive shaft and rotor assembly is packed in an integral unit with the engine supported on rubber mounts at the top and bottom and attached to the welded framework of the forward fuselage.

In the center section there are also the engine accessories and the 32 USG (121 litres) fuel tank.

The main rotor is driven through a centrifugal clutch and a two-stage planetary transmission with a 9:1 motor/rotor reduction ratio. A free-wheeling mechanism is incorporated in the transmission.

In the center section there is a generous 40 lbs (18 kg) luggage compartment accessible from the starboard side.

The center section is enclosed by metal cowlings. The aft body cowling has airventilation grilles to improve cooling. The engine exhausts are of the top behind the mast. Below the engine there are two grilles for air inlet.

The Bell 47B has a quadricycle landing gear. The front wheels are castering while the rear wheels are fixed.

The tailboom is also made of welded steel tubes. It is triangular in cross-section and serves as support for the anti-torque rotor drive-shaft. The upper part is fitted with fairings while laterally it is covered with fabric.

At Larry Bell’s specific request the fuselage of the Bell 47B was fully enclosed, but in the practical use pilots found that the triangular base and slope of the tail in some situation would cause the helicopter to pitch. For this reason (but also in order to lighten the aircraft as much as possible) most operators stripped off most of the panels, fairings and fabric. By doing this pre-flight inspections were consequently greatly facilitated.

The Bell 47D1 version introduced to the civil market in 1949 was intended precisely to satisfy this customer need. It also offered better performance and a greater payload.

This model was developed by Bell in order to offer a valid competition to the Hiller 360 manufactured by United Helicopter Inc. which started its series production that year.

Contrary to the two prototypes the Bell 47Bs manufactured in series were equipped with a fixed horizontal stabilizer which was a mandatory requirement on all Bell 47 models with covered tail booms. The stabilizer greatly improved the flying characteristics of the early helicopters.

The anti-torque rotor (the blades were also made of laminated wood) is driven by a tubular shaft and is controlled by cables and pulleys.

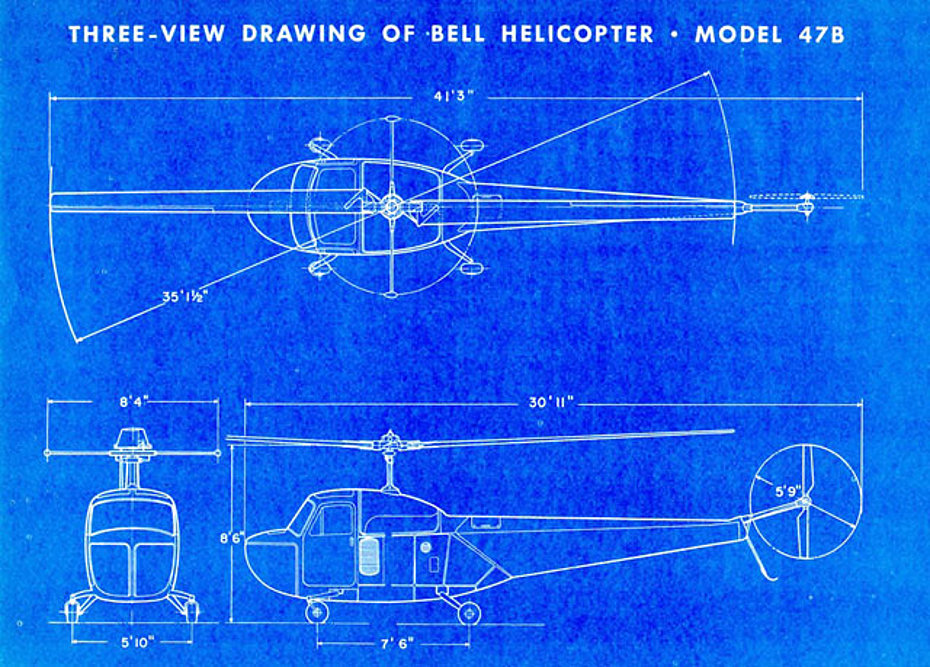

Dimensions

The main rotor of the Bell 47B has a diameter of 10.70 m/35 ft 1.5 in (rotor disc area of 89.59 square meters/965 sq ft), while the tail rotor has a diameter of 1.65 m/5 ft 8.13 in (2.34 sqm/25.31 sq ft rotor disc area). The fuselage has a length of 9.58 m/41 ft 2.57 in, while the height measured at the helicopter mast is 2.84 m/9 ft 4 in.

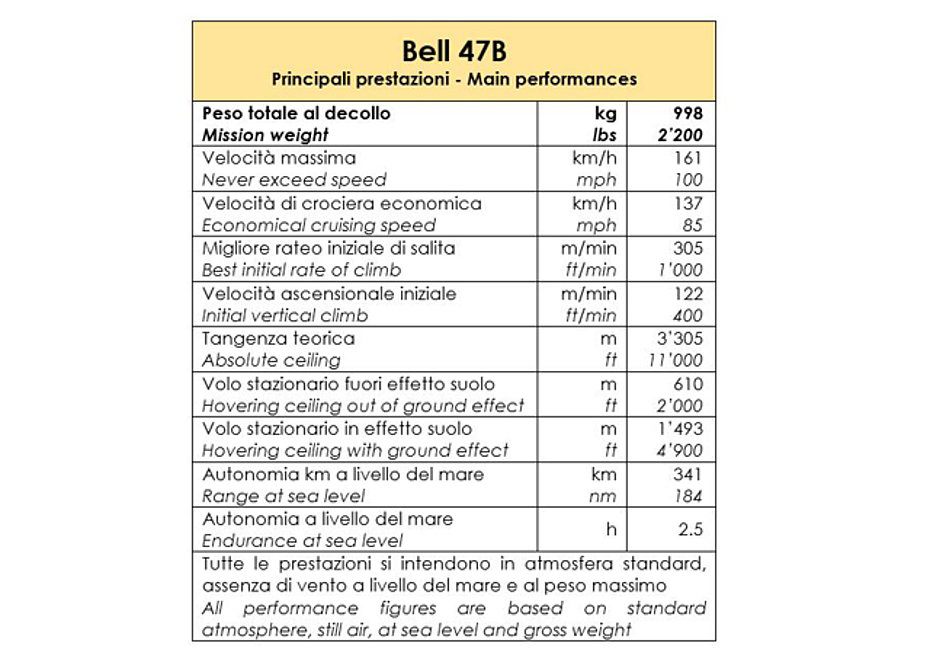

The empty weight of the aircraft is approximately 681 kg (1'501 lbs), while the maximum takeoff weight is 998 kg (2,200 lbs).

Deducting the pilot's standard weight (77 kg/170 lbs) and with a fuel and oil reserve for one hour of flight (36 kg/79 lbs) the payload was about 205 kg (452 lbs).

The Bell 47B in Switzerland

The Bell 47B was the first helicopter to fly in Switzerland. It was officially presented in the area of the Allmend of Wollishofen near Zurich in the afternoon of October 14, 1947.

The aircraft presented was the aforementioned G-AKCX belonging to Irvin-Bell Helicopters Sales Ltd. and was piloted by the English pilot Alan Bruce Hamilton "Jimmy" Youell who had obtained his helicopter pilot license at the Bell school.

The helicopter was invited to Switzerland by Farner-Werke AG in Grenchen managed by Willy Farner who spent some words to underline the peculiarities of the strange flying machine in front of the numerous audience rushed to the scene to observe the flight demonstration.

The helicopter was equipped with dual controls to offer some Swiss pilots the opportunity to execute short flights along with Youell acting as instructor. The demonstration carried out in Wollishofen did not make a great impact. However it is important to remember that that historic event marked the start of a new chapter in the history of civil aviation in Switzerland.

The brief appearance of the Bell 47B gave for example the opportunity to journalists to begin to deepen their knowledges in the rotary-wing field. The aviation magazine Aero Revue published a long article providing both technical and historical information about the helicopter. The journalist also explained how a pilot controlled the helicopter.

It is almost unbelievable but after the flights of G-AKCX almost a year passed before another helicopter flew in Switzerland! The helicopter concerned was the Sikorsky S-51 G-AJHW piloted by Alan Bristow.

Footage

Watch this color footage starring Bell 47B SE-HAB: https://www.youtube.com/watch?v=kwzdYzaYgPQ

Strange but true

The Bell 47B's type certificate was only released on November 4, 1947 when this version was already out of production.

HAB 04/2017