Bell 47J Ranger - History and technical description

In Autumn 1956 Bell Aircraft Corporation’s Helicopter Division in Fort Worth announced the addition of a new helicopter to its commercial line. The helicopter concerned was the Bell 47J Ranger derived from a prototype known as the 47G-1. Here is a summary of the story of the genesis of the Bell helicopter of the “Jey” series.

Origins of the Bell 47J Ranger

In 1953 a preliminary market survey indicated that a market existed for a low cost, four-place utility helicopter and Bell decided to build a prototype that with the passing of time was submitted to extensive modifications leading to the creation of the 47J Ranger.

Bell’s governing policy was to proceed one step at a time and be certain that the company was on firm ground with each step in order to develop a proved, dependable helicopter based on sound economics in the shortest possible time. The program was sponsored entirely by company funds.

The first step was to develop a basic four-place configuration flying as fast and economically as possible.

Due to heavy workload in the engineering department, and to expedite the program, an independent group was set up to operate at an outside facility (Harper Engineering, Dallas). Work began on November 1, 1953.

The basic ship, officially designated Bell 47G-1, was designed as a modification of a Bell 47G by a team of approximately twenty men working as a project group.

Engineering was finished in 60 days and the ship built and flown within 120 days of the starting date. The entire job was carried out in the outside shop with the exception of the Plexiglas bubble, which was manufactured in the Bell bonding department, while the final assembly and inspection were carried out by Bell experimental flight mechanics.

During this phase of the program very little time was spent on customer appeal, and the ship was primarily an engineering flight test bed.

The prototype received the registration N2474B and made its first flight on March 5, 1954 at the Bell plant in Hurst/Texas with test-pilot William (Bill) Quinlan at the controls.

After two months of extensive flight testing the basic configuration was deemed feasible from the engineering point of view.

The second test consisted in refining the ship for customer appeal and maximum utility. During this phase of the Bell 47G-1 development, Bell Sales Engineering was in command, and the Design Engineering Department supplied the designs for the suggested furnishings and equipment.

Two major modifications and two extensive trips around the United States were made to bring the ship to its optimum configuration and to gain an appreciable amount of service experience on both the basic ship and the equipment.

The first modification consisted in adding cowling, contour formed gas tanks, a semi-monocoque tail boom, a new cabin above the floor and an internal litter kit. The engineering work was accomplished by a group of four engineers working right beside the ship on the hangar floor. The ship first flew in less than two months from the starting date. In this configuration the ship was presented in many military and civil air centres including the National Air Show in Dayton in September 1954.

Several hundred passengers were given rides and the aircraft was flown over a hundred hours in a month.

The second modification was to install the Lycoming VO-435 engine (which powered the Bell 47G2), develop a hand crank, develop a rescue hoist, modify and install a float kit, and have a new interior added. Two groups worked together with minimum delay and the ship was back in the air within a month. The second service tour comprised about 100 hours of flight in approximately four weeks. During this time the various kits were installed and demonstrated many times.

This step in the program allowed the company to gain valuable service experience with the experimental equipment and granted a rather large number of key people in the helicopter industry to become familiar with the new helicopter.

Up to this point it had been a low cost project with an experimental ship that had been overweight due to the many hasty modifications made. On many details optimum design had been compromised to save time and money, and many improvements suggested by potential customers had been passed up during modification of the first ship due to strict deadlines. The consensus of opinions of all the people that saw the ship encouraged Bell to enter into the third step in the 47G-1/J programme: design a production 47J.

The experimental ship was handed back to the engineering department for further tests and refinements that would assist in the production design. Rotor and powerplant development was carried out separately on a Lycoming powered Bell 47G. The standard Model 47 rotor had been used on the experimental 47G-1 and parts life arbitrarily limited to grant equivalent safety factors. The production design proceeded according to conventional aircraft practices with many hundreds of hours spent in perfecting details. At this point the managers at Bell Aircraft were sure that they were proceeding on firm ground.

Development and technical aspects

Selecting the seating arrangement and laying out the cabin configuration was a vital job requiring many considerations. The arrangement having a single pilot forward was selected. It caused the least centre of gravity (CG) shift with variations in the disposable load. It allowed space for litters or cargo, and as passenger ship it isolated the pilot better than the conventional two forward and two back arrangement normally used in aeroplanes. The rear seat width and leg clearance for the middle passenger were determined by comparison with several popular automobiles, as well as by the crude wooden mock-up.

The instrument panel from the Bell 47G was retained, but the pedestal was positioned to the pilot’s left where all switches and levers would be accessible to the pilot’s left hand. With the exception of the magnetic compass the instruments were all inclined to avoid a distorted vision. This arrangement permited the best possible forward view, and was the most convenient when the pilot used the rescue hoist.

In order to minimize the CG shift the firewall and the rear seat were moved back until they cleared the fan pulley. The fore and aft controls were rerouted to the side of the fan. Before building a ship, this firewall arrangement was duplicated and the effect of the proximity of the firewall arrangement on the fan air inflow was checked in flight. Engine cooling was not appreciably affected.

The first version of the 47G-1 was simple and weighed only 1'465 lbs. In the first version of this prototype the open tail boom and centre frame of the 47G were retained. The rotor and power plant were also from the 47G.

The front of the 47G centre frame was modified to support the 47G-1 cantilever floor structure and the firewall. The firewall was stainless steel and supported the rear seat and part of the two fuel tanks. At the beginning these were simple wrapped sheet containers that approximated the contour of the ship. Later, formed fuel tanks from the 47H-1 were added since the two ships were very similar from the firewall aft.

The Plexiglas bubble was one of the most difficult parts to be made accordingly. The bubble shape was important for the ship appearance, and the optical qualities, of course, had to be good for both the pilot and passengers themselves. At the same time the bubble had to be light and strong.

A large single-piece bubble was chosen for best visibility and lowest ultimate production cost. Up to that time all of the Model 47 bubbles were free-blown to a nearly spherical shape. The large streamline shaped 47J bubble was made by drawing a free bubble into a vacuum box, then allowing it to collapse against a cloth-covered plaster mould. This process was workable, but proved to be quite tedious and time consuming. It was hard to get a uniform thickness and the bubbles tended to be soft in the front. Therefore a better method was used and consisted in free-blowing the bubble from a three dimensional clamp-ring thus approximating the edges of the supporting structure. By free-blowning the shape when lofting the ship’s lines, a very pleasing cabin could be made by means of this method. The optical qualities actually had to be preformed to fit the three-dimensional clamp-ring before the final blowing operation.

After the first version was flight tested, the ship was modified to improve its appearance and to increase the speed. The original cabin shape was made as nearly as possible to that of the 47H-1, so that it was not difficult to adapt the 47H-1 semi-monocoque tail boom and contour shaped gas tanks to the 47J.

In early Bell models, such as the 47B and 47D, difficulties were experienced with the the covered tail boom due to the triangular shape. This shape tended to introduce pitching when the helicopter was yawed, therefore the 47G-1 new tail boom (almost identical to the one used by the 47H-1) had a symmetrical shape and didn’t affect the flight characteristics other than to provide better streamlining. When everything had been taken in consideration the weight was about the same for either the tubular or semi monocoque tail boom.

The lateral screen type cowling was mainly added for aesthetic reasons, but it also reduced the drag somewhat at high speeds.

The curved skid landing gear was another novelty on the 47H and 47J. The curved cross tubes not only looked better, but also appreciably reduced the weight and drag of the landing gear. The curved tube functions exactly like the straight one with vertical legs in absorbing landing shocks. Practically all of the energy absorption occurs inboard of the radius in the curved tube, so that the mathematical analysis is the same for either type of cross tubes.

In the rear folding seats the helicopter could carry three passengers or 1.71 cubic metres (50 cubic feet) of cargo as long as the same didn't weigh over approximately 272 kg (600 pounds). With the medevac kits installed the aircraft was able to carry two litter patients, or perform hoist rescues.

The hoist installed was a standard Navy electric rescue winch and was capable of liftting a man about 30 metres (100 feet) per minute. It was controlled from the pilot’s cyclic stick, and the hook was visible to the pilot at all times. This kit was designed and built in 30 days. It was ground tested briefly using a cable over a pulley in the rafters of the hangar, then with the helicopter hanging ten feet in the air on a crane. However most of the testing was carried out with the helicopter hovering about twenty feet in the air. The easiest way to employ the winch was to hover into the wind and pick up the load with collective pitch. The electrical winch worked equally well both when the helicopter was equipped with as well as floats. Both kits greatly enhanced the utility of the 47G-1/J.

The centre of gravity limits for the 47J were almost the same as for the 47G.

However on the 47J the synchronized elevator was moved forward two feet on the fuselage in order to keep it in the rotor downwash and improve the rearward flight characteristics.

The helicopter was equipped with hydraulic controls so that stick forces were considerably reduced. The rotor and power drive systems were developed and improved on the 47J.

The Model 47 rotor had to be developed structurally for increased power and weight of the 47J. Although the standard rotor could carry loads, the life of some parts was not long enough for a practical commercial helicopter. Structural development was centred around strain gage testing which was started on the Lycoming powered Bell 47G.

After the success of the various tests made with the prototype known as Bell 47G-1 N2474B, Bell engineers finally designed the Bell 47J Ranger which was almost identical to its predecessor.

Start of the production in series

The first helicopter of this new series (serial number 1420) received registration N2478B and was completed on November 1, 1955. Along with the second aircraft (s/n 1421) registered N2479B this helicopter was extensively tested and used as a factory demonstrator.

On August 23, 1956 the Bell 47J Ranger obtained the CAA certification.

Production in series started in the following months due to the fact that Bell was completing the production of the HUL-1 for the US Navy, the military counterpart of the 47J.

In 1957 the initial basic price of the Bell 47J Ranger was 69’500$ (Sfr. 298’000 in 1957 or 1'160'000 nowadays - 2015 -) or 73’836$ when equipped with radio, fire extinguisher, night lights, rotor brake, heater, custom paint job and deluxe interior.

Early Bell 47J Ranger had wooden main rotor blades. These were then replaced with metal blades and therefore the maximum take-off weight was increased from 1’165 kg (2’565 lbs) to 1’270 kg (2’800 lbs).

Compared with wooden blades, metal blades have a longer life in all kinds of weather, better tracking, less maintenance and improved power-off landing characteristics.

Initially the period between overhauls was 600 hours, at that time the longest period in the helicopter industry. Later the interval was extended to 1’200 hours.

A total of 135 Bell 47J Ranger were manufactured (serial numbers eligible 1420 thru 1443, 1559 thru 1581; 1712 thru 1802) at Bell’s Hurst plant locatet in Texas.

The successive versions were the J-2 and J-2A. The Bell 47J-2 is similar to the 47J except the basic helicopter incorporates metal main rotor blades, fixed stabilizer, VO-540 engine, blue tinted bubble and windows together with miscellaneous minor improvements.

The Bell 47J-2A is similar to the 47J-2 except for increased weight, the installation of collective boost system, addition of main rotor tip weights, a change in the C.G. limits, and miscellaneous minor improvements.

At customer request the Bell Model 47J helicopters could be converted to Model 47J-2 or J-2A.

Employment

The civilian Bell 47J Ranger were primarily used for passengers and goods transportation, executive and commuter flights, ambulance services, reconnaissance, liaison, observation and photographic flights.

Technical description

The Bell 47J Ranger is a four-seater helicopter of standard configuration with a two-blade main rotor with a stabilizer bar and a two-blade tail rotor. The fuselage consists of three main sections: the cabin, the centre frame and tail boom.

The cabin is protected by a "bubble" made of Plexiglas granting excellent visibility in all directions, and is accessible from each side through quickly removable doors.

The pilot is seated centrally in the front while the three passengers are seated behind him on a foldable bench.

When the helicopter was employed for search and rescue duties or as an aerial ambulance the foldable bench could be removed in a matter of minutes without the use of tools to enable the installation of two stretchers on a parallelogram rack as used in a typical Army field ambulance plus a jump seat for a medical attendant.

With the port door removed a trap could be raised to allow for the use of an internal electrically-powered hoist for rescue work.

A firewall of corrosion resistant alloy is installed between the engine compartment and the cabin area.

The centre frame, or engine section, consists in a tubular structure of welded steel tubes. This section provides support for the engine, its accessories and the cabin. It is provided with fittings for attachment of the curved skid landing gear and provisions for the attachment of float type landing gear.

The tail boom

The semi-monocoque tail boom has a symmetrical shape. A synchronized elevator also constructed with aluminium alloy is installed on the tail boom. Its motion is controlled by the fore and aft cyclic control stick. The elevator is attached to the tail boom by means of anti-friction bearings and bolts. The elevator makes cabin load variation less critical and increases manoeuvrability.

A two-blade tail rotor is installed on the aft end of the tail boom, and is driven by an auxiliary shaft connected to the free wheeling side of the transmission. The tail rotor blades are constructed with aluminium alloy like the tubular type rotor guard installed to protect the tail rotor blades, and acts as a personnel guard.

Engine and transmission

The Bell 47J Ranger is powered by a 260/194 kw/hp six-cylinder air-cooled Lycoming VO-435-A1B (or -A1D or also -A1E) derated to develop 179/240 kW/hp for two minutes and 164/220 kW/hp continuous. The engine is mounted vertically in the centre section. Easily removable side cowlings expose the engine for maintenance.

Mounted directly on top of the engine there is the -600 transmission containing two sets of planetary gears with an overall reduction ratio of 9.1. The transmission also drives the tail rotor, the cooling fan, the generator and transmission tachometer generator.

Transmission incorporates a freewheeling unit and a centrifugal clutch allowing autorotation landings.

The two interconnected gravity fuel tanks (the engine runs with 80/87 minimum grade aviation gasoline) located on the centre of gravity have a total capacity of 35/132 USG/litres (usable quantity 34.6/131 USG/litres).

The electrical system incorporates a 50 ampere 28 volt generator, and a battery. Obviously there is also an external power receptacle.

Electrical system

The electrical system consists of a 28 volt DC system, a 28 volt 50 ampere generator, a 24 volt, a voltage regulator and originally a 15 ampere-per-hour battery.

The ignition switch and electrical starting button are installed on the instrument panel.

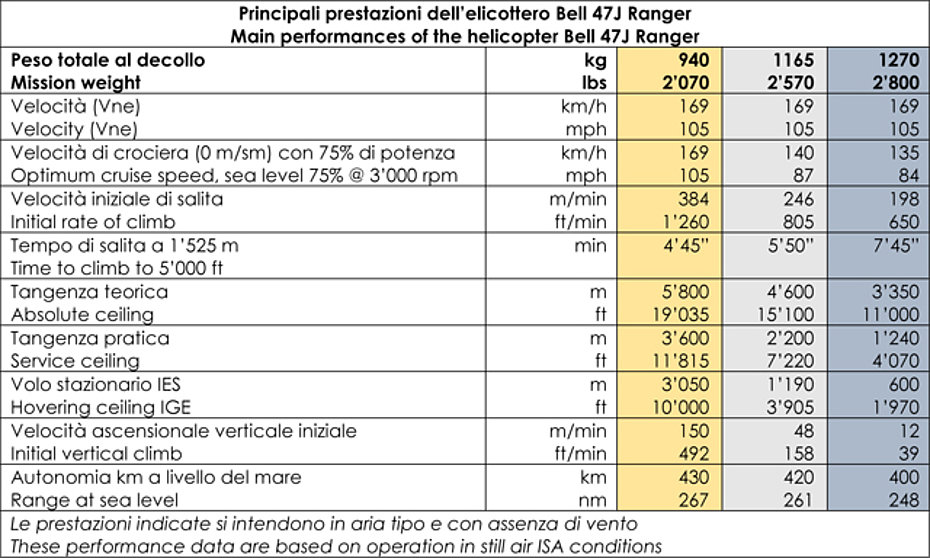

Performance

Below is a table with the performance data of the helicopter:

Rotor and engine limitations

During normal operations in flight the main rotor rev must be kept between 333 and 370 rpm, while the engine rpm must be kept between 3'000 and 3'200 rpm.

Dimensions, weights and payload

The main rotor of the Bell 47J Ranger has a diameter of 11.32 m/37.4 ft (main rotor disc area 100.59 sm/1096.4 sq/ft), while the tail rotor has a diameter of 1.78 m/5.9 ft (tail rotor disc area 2.48 sm/5.9 sq/ft). The fuselage has a total length of 9.87 m/32.6 ft. The max height of the helicopter is 2.83 m/9.3 ft.

The standard empty weight of the helicopter fitted with skid-type landing gear is of approximately 750 kg (1’650 lbs), while its max take-off weight (MTOW) is 1'270 kg (2’800 lbs).

Early 47J Ranger still used wooden main rotor blades and therefore the max take-off weight was limited to 1’165 kg (2’565 lbs).

With metal rotor blades and the 240 hp kit installed, the max take-off weight could be increased to 1’270 kg (2’800 lbs) or 1’293 kg (2’850 lbs). This modification allowed a 40% increase of the payload.

By deducting the standard weight of the pilot (80 kg/176 lbs), and with a fuel and oil reserve for one hour of flight (52 kg/115 lbs) the useful weight of the Bell 47J Ranger with wooden blades, in its original configuration, is approximately 283 kg/625 lbs.

The spacious baggage compartment, designed into the semi monocoque tail boom, easily accommodates up to 113 kg/250 lbs of luggage. This compartment measures 63 x 73 x 88 cm or 0.4 cubic meters (25” x 29” x 35” or 14.5 cubic feet). The compartment as well as the cabin doors are provided with handles which may be locked.

Accessories

The list of additional accessories available included: floats for amphibious operations, electrically-powered hoist for rescue operations, cargo transport installations, single point suspension system hook for external loads, two litters and medical attendant seat in the cabin for aerial ambulance operations, IFR instruments panel and radar, additional fuel tanks for greater range, cabin heater, rotor brake, night flying equipment (which included position light, landing light, instrument panel illumination and cabin interior light), fire extinguisher, first aid kit and a shoulder harness kit.

The Bell 47J Ranger in Switzerland

The story of the first "Ranger" registered in Switzerland (which was also the first to be delivered in Europe) is directly linked to Hermann Geiger, the legendary Swiss pilot nicknamed “The glaciers pilot”.

Geiger, very popular especially in Switzerland due to his rescues in the Swiss Alps at the controls of a Piper PA-18 125 Super Cub, knew that the helicopter was much more suitable than aeroplanes in aerial rescues activities in the mountains as well as the transportation of people, goods and building materials.

It should be remembered that in that period Geiger was not only employed by the Valais Section of the Aero Club of Switzerland as a commercial pilot and instructor, but also as the chief-pilot of the Swiss Life Saving Society (which on March 19, 1960 became the Swiss Air Rescue Guard (SARG), nowadays known worldwide as REGA). At that time SARG’s activity was largely based on the voluntary work of its members. Therefore, seen the limited financial resources, in December 1955, in SARG’s chief-pilot shoes, Geiger addressed a sponsorship request to the Association of Swiss Consumers' Cooperative Societies (usually simply known as “Coop”) claiming the need for a helicopter, but how to raise the money needed for the acquisition of a helicopter?

Fortunately the solution was soon found. In 1956, between April and the end of August, pamphlets and small paper envelopes expressing SARG’s need for the helicopter were distributed through the Swiss supermarket chain Coop. The population responded by donating half a million Swiss Francs: “Many coins for a miracle” wrote a journalist.

Last but not least in recognition of SARG’s humanitarian service, Bell Helicopter itself contributed 2’300$ towards costs of its acquisition costs, and in a memorable humanitarian gesture Bell’s Swiss representative Fred Forrer donated his sales commission on the helicopter as well. By the end almost half million Swiss Francs were raised and 350’000 Swiss Francs were invested in the purchase of the Bell 47J Ranger.

The HB-XAU arrives in Switzerland

The aircraft (s/n 1426 b/y 1956) was delivered to Switzerland by cargo plane and arrived at Zurich-Kloten on January 20, 1957.

There it was immediately assembled by engineers of the Pilatus Air Service under the supervision of Joe Mashman, Bell’s famous test pilot who had been sent to Europe to introduce the new helicopter.

On January 30, the new helicopter, assigned with Swiss registration HB-XAU, was checked by technicians of the Federal Office for Civil Aviation (FOCA) and Mashman carried out a series of test flights. In the early days of February the American pilot flew to Germany to introduce the HB-XAU to a number of potential customers.

Back in Switzerland he trained a group of Swiss pilots. Among them were Sepp Bauer, Oswald Matti and Fred Forrer.

At that time the upper part of the HB-XAU fuselage was painted in red. A sticker with the German writing “Schweizerische Lebensrettungs-Gesellschaft – Rettungs-Flugwacht” was added on the left side, while another in French language “Societé Suisse de sauvetage – Garde aérienne” was added on the right side along with an orange/white sticker with the “Coop” logo.

On February 28, after the delivery ceremony which took place in Freidorf-Muttenz near Basle, the new helicopter was officially handed over to Hermann Geiger. In the afternoon Joe Mashman carried out a demonstration flight displaying the versatility and manoeuvrability of the helicopter in front of a crowd of about 4,000 people who watched enthusiastically the evolutions of the American pilot.

As established in the contract signed between Coop and the SLSS, later on March 22, HB-XAU was transferred to Sion (Valais). This time the flight was carried out by Hermann Geiger who ony a few days before, on March 19, had received his private helicopter pilot license. A few months later, on June 8, OFAC issued Geiger helicopter commercial pilot license nr. 28.

On March 31 a new ceremony was organised in Sion to celebrate the arrival of the helicopter which was blessed by Nestor Adam, the bishop of the Sion diocese.

From that moment on, Geiger started to use the helicopter more and more frequently. Especially in the Valais the red and silver "Ranger" quickly became a synonym of aerial rescue.

Geiger, who was employed as a pilot on behalf of the Valais Section of the Aero Club of Switzerland, later obtained permission from the FOCA to employ the helicopter for commercial transportation of people, goods and building materials.

During the period March 1-4, 1957 Geiger was trained in helicopter mountain landing technique by his friend-instructor Sepp Bauer.

In fact, despite the limited performance of the Bell 47J Ranger, Geiger and later (from March 4, 1959 on) Fernand Martignoni frequently used HB-XAU for rescue and transportation operations at high altitude until the arrival of the more powerful AB47J3B-1 HB-XBR.

Surprisingly HB-XAU was never damaged by the two Valaisan pilots, and this confirms their great skills as helicopter pilots!

Ernst Bänzinger was the first mechanic entrusted with the maintenance of the HB-XAU. However, for the most important maintenance work, such as the 300-hours inspection, the helicopter was conveyed to Cascina Costa di Samarate (Italy) where Agusta had its manufacturing plant which was only about one hour of flight far from the airport of Sion.

From February 1st, 1958 Armand Geiger (nephew of Hermann Geiger) took over the maintenance and overhaul of the helicopter, sometimes in collaboration with Agusta’s engineers.

The HB-XAU remained in service with SARG until March 1968 when it was sold to Heliswiss.

The use in Greenland

From 1968 on and for four seasons HB-XAU was hired by the Geological Survey of Denmark and Greenland (Grønlands Geologiske Undersøgelse or GGU in local language).

From 1965 to 1985 Heliswiss was in fact entrusted by GGU to organise the transportation of geologists working in Greenland during the summer season (usually from late May until September).

For safety reasons two helicopters were employed together simultaneously. In that period the HB-XAU flew along with the Agusta-Bell 47J Ranger registered OY-HAV.

The tragic end of the HB-XAU

HB-XAU was cancelled from the Swiss civil aircraft register following a tragic accident which took place on June 16, 1971 while in service in Greenland.

That day Austrian pilot Peter Gschwend, who was flying the aircraft on a routine mission, disappeared in the sea. Peter Schmid who was flying OY-HAV on the same route (the two helicopters took-off from the same point with a short interval) suddenly lost all radio contact.

Despite an extensive search action neither the helicopter nor the pilot’s body were ever found. Therefore the cause of the accident could never be ascertained and the tragedy remains wrapped in mystery.

The helicopter was most probably lost due to sudden and severe mechanical failure (for example as a result of a mast-bumping) or a sudden severe health problem of the pilot such a heart attack.

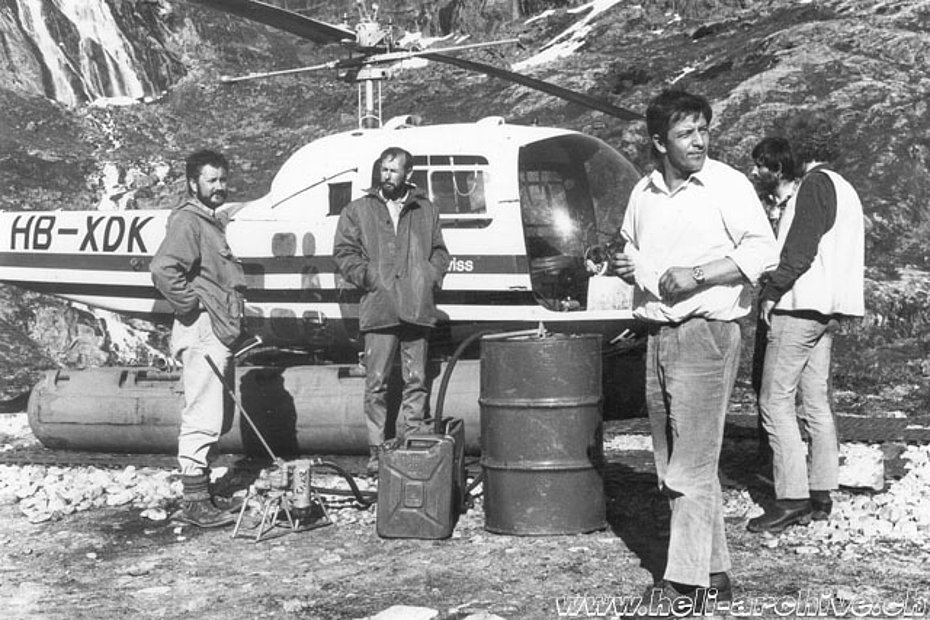

HB-XDK - From Africa to Greenland

The second Bell 47J Ranger to be registered in Switzerland was HB-XDK purchased in the United States in 1971 by Swiss missionary Ernst Tanner, the founder of Helimission.

With the serial number 1798, HB-XDK (ex N6779D) was one of the last “Rangers” of the J series manufactured before the introduction of the improved J-2.

HB-XDK was sent to Switzerland and was assembled in Belp by the engineers of Heliswiss.

On November 17, 1971 the helicopter made its first test flight in Belp/BE with the Swiss registration.

Meanwhile in addition to his airplane pilot license Ernst Tanner also obtained his helicopter pilot license.

On January 17, 1972 with a flight experience of only 38 hours under his belt, the “flying missionary” as he was nicknamed, along mechanic Marcel Gasser, took-off from Trogen (Canton Appenzell Ausserrhoden) and after a long journey, on February 2, landed in Cameroon. That is where the helicopter was used to transport people, medicines and supplies to various religious missions.

As predicted by Tanner, HB-XDK could travel within a few minutes over distances that required hours on foot. After nearly two months of service in Africa, by the end of March the first helicopter of Helimission headed back to Switzerland. Instead of passing across the Strait of Gibraltar, this time the Swiss crew decided to fly across the Mediterranean sea between Tunisia and Sicily. On April 3, after many vicissitudes, the helicopter finally landed in Trogen.

This model proved to be inadequate for the needs of Helimission. Particularly in Africa the high temperatures significantly reduced the not very brilliant performance of the Ranger. Helimission replaced it with a Jet Ranger. The old HB-XDK was chartered to Heliswiss who sent it to Greenland where it was employed by GGU to replace the HB-XAU.

Unfortunately on March 31, 1975 the helicopter was destroyed in an accident near the village of Court (Canton of Bern).

During take-off on snow covered terrain, the left skid remained trapped under the icy surface. The inexperienced pilot, surprised by the helicopter behaviour, lost its control. A few moments later the aircraft rolled-over and caught fire.

Nobody was injured but HB-XDK was damaged beyond repair and it was therefore cancelled from the Swiss civil aircraft register.

In Switzerland other models of the “J” series (J2, J3 and J3B-1) were tested or registered. However their stories will be/are presented separately.

Did you know that…

On November 25, 1956 the Bell 47J Ranger N2464B completed a 27’300 km (17'000 miles) tour in Central and South America. The helicopter concerned was nicknamed “The Silver Hummingbird” (in Spanish El Picaflor plateado) and completed 83 days tour logging altogether in 250 hours of flight through all types of weather and over the roughest terrain.

The tour started on September 4, 1956 with two aims: to introduce the new commercial helicopter to the Latin American market and to exhibit the Ranger’s performance capabilities. During the tour Joe Mashman carried out a dramatic evacuation flight in the Andes during which the helicopter crossed a mountain chain at an altitude of 5’180 meters (17,000 feet).

Along with the Bell 47G registered N975B the Bell 47J Ranger N2838B was the star of the popular television series “Whirlybirds” produced by Desilu Studios in the late ‘50s.

In March 1957 two Bell 47Js were bought by the United States Air Force as presidential transport and designated it as H-13J. On July 12, 1957, Dwight D. Eisenhower became the first President of the United States to fly in this helicopter.

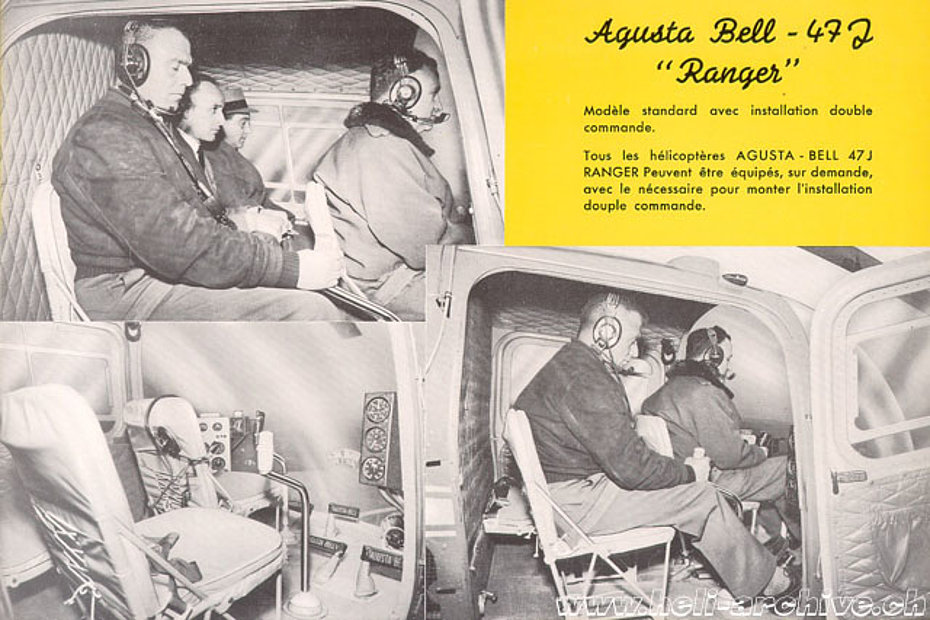

Since 1957 the 47J Ranger was built under license in Italy by “Costruzioni Aeronautiche Giovanni Agusta”.

The first Bell 47J Ranger to be registered in Italy (I-AGUS), was manufactured in the United States (s/n 1425). This aircraft was extensively used as a demonstrator.

In Italy the 47J Ranger was nicknamed “Jota”.

The Italian company also introduced some modifications to the basic J model. Upon customer request the AB-47J could in fact be fitted with a dual control kit. Another optional kit enabled the helicopter to carry four passengers behind the pilot.

Agusta also manufactured three sub-variants known as J-3, J3B and J3B-1 which were extensively used by the Italian Armed Forces, Carabinieri, Polizia, Vigili del Fuoco and Guardia di Finanza. According to information gathered Agusta manufatured a total of 74 AB-47J.

Four AB-47J Rangers (registrations I-EUNO, I-EDUE, I-ETRE, I-EQAT) were also used by the Italian company Elivie as commuters between Naples and the gulf islands. The seasonal shuttle service officially started on July 19, 1959 and was suspended for financial reasons during the summer of 1970.

Agip Mineraria (Agip is an Italian acronym which means Azienda Generale Italiana Petroli - General Italian Oil Company), used some AB-47J Ranger (for example I-AGID, I-AGIZ, I-MINS, I-SNAR) for its aerial activity which included geological surveys and supply flights. Among the Italian companies which used the AB-47J Ranger there were also Compagnia Italiana Elicotteri and Elitaliana.

Special thanks

I wish to express my gratitude to Ruedi Renggli, Paul D. Faltyn, Ernest Devaud, Bob Petite, Jeff Evans and Markus Burkhard for their precious help in providing information, photographs and technical documentation.

Videos

Take a look at these videos starring the Bell 47J Ranger HB-XAU and the popular alpine rescue pilot Hermann Geiger:

Delivery ceremony in Freidorf-Muttenz, February 28, 1957: http://xml.memovs.ch/f0081-g17a.xml

The HB-XAU is officially introduced at the airport of Sion on March 22, 1957: http://xml.memovs.ch/f0005-013.xml

HB-XAU being used for a medical evacuation in the Valaisan Alps. The video is commented by Jean-Jérôme Pouget Air Glaciers’ chief-pilot: http://xml.memovs.ch/f0032-057-010.xml

Hermann Geiger helps a worker prepare a landing site and then transports some Jerry cans in the Valaisan Alps – start 7’30”: http://xml.memovs.ch/f0081-g24.xml

HAB 05/2015