Helitech-Sikorsky S-55T - History and technical description

Origins

The idea to install a gas turbine on the Sikorsky S-55 originally equipped with a radial engine was developed by Westland Aircraft Ltd. in the late 1950s when the Westland Whirlwind Series 3 was introduced on the market.

The prototype made its first test flight on February 28, 1959 powered by a General Electric (GE) T58 later replaced by a Bristol Siddeley Gnome H.1000, the British version of the GE.

About ten years later in the United States Aviation Specialties Inc. based in Mesa/Arizona, also had the idea to convert the ageing Sikorsky S-55 into a gas turbine powered helicopter.

This reliable and robust helicopter, which had been produced in over 1,250 units by Sikorsky (and was also produced under license by Westland Aircraft, SNCASE and Mitsubishi), was on its way out after the apparition of new generation helicopters, like the Bell 204 and 205 which become extremely popular during the Vietnam war.

The American armed forces were the first to replace the H-19 (military designation of S-55) with the new models, and therefore surplus H-19s were sold on the civil market.

Thanks to a conversion kit and a Supplemental Type Certificate (STC) Aviation Specialties Inc., founded in 1952 and specialized in the overhaul and repair of airframes, engines, instruments and aircraft modifications, decided to give a second life to the S-55. This helicopter was perhaps a bit clumsy and antiquated but still capable of performing valuable services on the civilian market.

The first prototype of the S-55T was registered N1255T and made its first test flights in 1969. During the annual meeting of the Helicopter Association of America that took place in Las Vegas between January 11-14, 1970, Aviation Specialties announced that S-55T certification would soon be released, and that the first aircraft would be available by April 1970. However another year passed because the Federal Aviation Administration (FAA) released the certification only on January 19, 1971.

The conversion required about three to four working months at a cost of about 125,000 $ (1970).

In the meantime a new company was formed to carry out the conversions, Helitech Corporation, which was responsible also for marketing the S-55T in the USA. Aviation Specialties International was purely a marketing company responsible for international sales and export of the aircraft.

At least 100 conversions were anticipated. At the beginning of February 1973 20 aircraft had been sold to operators based in Canada, Alaska, Europe, South America (7 were sold to the Fuerza Aerea de Chile) and the United States. The following year 8 conversions were completed. As of January 1, 1975 36 conversions had been completed. More recent sources indicate that about 50 aircraft were completed.

The initial cost for the conversion rose to 140-150,000 (1975) to 175,000 respectively (1976). That same year a "new" S-55T was offered at about 240,000 dollars, much less than an Alouette III whose price was about 310-320,000 $ and less than half of a Bell 205A-1 (595,000 $). The two aircraft mentioned were perhaps the closest competitors of the S-55T in America.

The advantages of the turboshaft

Compared to radial engines turboshafts (also commonly known as gas turbines) have a higher power-to-weight ratio. They are lighter, much more compact with superior high altitude performance, especially when compared with piston engines not equipped with a turbo-charger.

Thanks to the automatic fuel control unit piloting is easier. The pilot in fact is not continuously forced to twist the hand-throttle to correct the engine/rotor rpm. Less vibrations and less noise also mean superior comfort.

Of course gas turbines are more expensive and sophisticated in design and manufacture. Maintenance of piston engines is simpler but needs to be performed frequently, while maintenance of gas turbine engines is complex, but inspection and maintenance occur at longer intervals.

For the S-55T Aviation Specialties selected the Garrett-Airesearch TSE-331-3U-303 with a maximum power of 626/840 kW/hp derated to 485/650 kW/hp. At that time this gas turbine had already been installed on fifteen different aircraft models and had totalled approximately 1 million hours of operation.

In the S-55T the turboshaft is mounted at an angle of 35° and the exhaust tube faces to the starboard side.

In order to compensate the considerable weight difference between the turbine (ca. 355 lbs - 160 kg) and the original engine Wright R-1300 (1,276 lbs - 580 kg) and keeping the center of gravity within the limits, various mechanical and electronic components formerly located in the tailboom have been relocated in the forward compartment. This improves their accessibility for maintenance and allows a wider range of load to be carried within the center of gravity limitations.

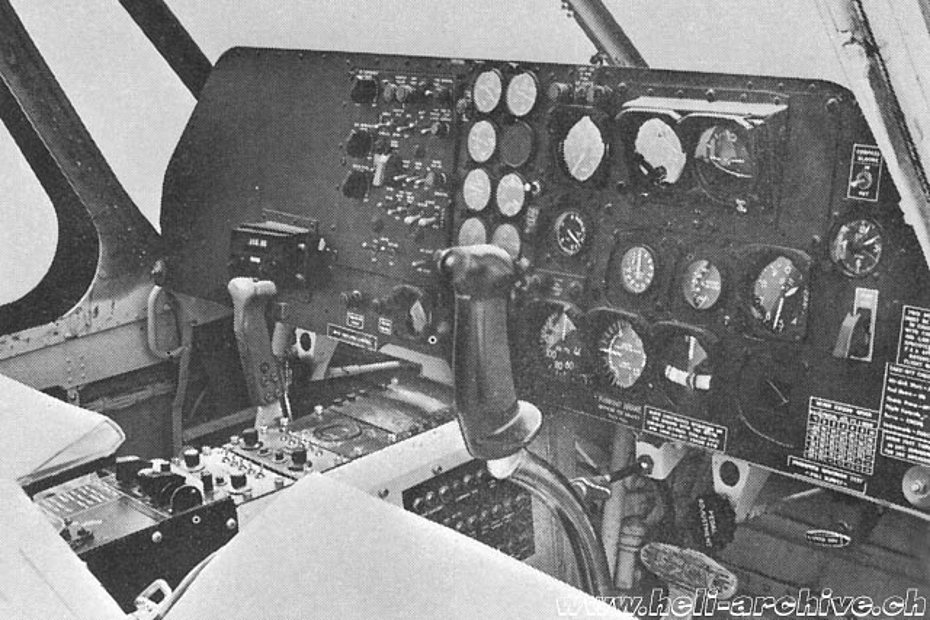

With the replacement of the original engine it obviously became necessary to proceed with a series of more or less important modifications: for example to the instrument panel, the engine cooling system, the transmission or the collective pitch lever only to mention some.

The conversion reduces the empty weight by approximately 900/410 lbs/kg which largely contributes to increase the payload.

Civil employment

On the civil market the S-55T has been mainly used for passenger and freight transportation, search and rescue flights, supply flights, offshore and firefighting.

Nowadays only a few aircraft remain in service. In the United States Pirate Airlift based in Sugar Hill (Georgia) use a S-55T for the transportation of building material, industrial lift, project works, tower construction, power pole setting and logging, while Golden Wings Aviation based in Brewster (Washington) operate some S-55T from May to August to dry cherries. During the last three or so weeks that cherries are on the trees, if they get wet, they can become damaged, usually splitting or developing mold. Therefore growers who don’t want to lose their crop hire helicopter pilots to stand by during the cherry season. Following rain the S-55T’s downwash shakes the branches, thus shaking off accumulated water.

Technical description

Externally the S-55T is almost identical to its predecessors powered with a radial engine. However a trained eye will immediately notice the gas engine exhaust tube and the spoiler added to improve the air inlet in the engine bay.

If we open the clamshell doors in front we will immediately find the differences. The conversion requires in fact a series of necessary modifications to adapt the installation of the gas turbine and its accessories.

The technical description can be seen at this link.

Performance

Thanks to the reduction of the empty weight and the power of the turboshaft the S-55T performs better than its predecessors. A brochure published in the 1970s indicates the following data (MTOW, standard conditions for temperature and pressure, sea level).

Maximum speed (Vne) 99 knots (183 km/h). Economical cruising speed 85 knots (157 km/h). Initial rate of climb 1,200 ft (366 m)/min. Max vertical speed 800 ft (244 m)/min.

Absolute ceiling 12,400 feet (3'780 m). Hovering ceiling in ground effect 10,000 feet (3'050 m). Hovering ceiling out of ground effect 6,700 feet (2'040 m). Maximum range with 180 USG (681 liters) of kerosene 370 miles (595 km). The average hourly consumption of the turboshaft is about 47-50 USG/hour (175-190 liters).

Dimensions, weights and payload

The external dimensions of the S-55T are identical to its predecessor. Its empty weight is about 4,850/2'200 lbs/kg and the maximum takeoff weight is 7,200 pounds (3'270 kg). The structural limit of the barycentric hook is 2,500 pounds (1'134 kg), but according to the information gathered usually during its employ in the Swiss Alps the helicopter transported a slung load of about 1,650 lbs (750 kg). In the large cabin (318 cubic feet or 8,93 m3) up to 10 passengers can be seated. Luggage, tool, etc. can be stowed in the large baggage compartment.

Optional equipment

The optional equipment list includes: 10 folding seats, bleed air heater and windshield defroster, ambulance installation with one to six litters, cargo hook (with electronic weight display), hydraulic winch with a lifting capacity up to 600 lbs (272 kg), fixed or inflatable emergency floats and agricultural kit for spray flights.

The Sikorsky S-55T in Switzerland

The story of the unique S-55T registered in Switzerland is related to Walter Ulrich Eisenhut who in 1969 founded Eisenhut Aviation in Mauren (Liechtenstein), a company that initially dealt with the sale of aircraft equipment and later started to sell helicopters as well.

In January 1972 at the annual exhibition of the Helicopter Association International, which took place in Las Vegas, Eisenhut met the managers of Aviation Specialties who were looking for a sales agent for Europe and during conversations with them became convinced that the S-55T could still render valuable services in the Old Continent.

At the end of the negotiations he obtained the representation for Europe and signed an agreement to purchase a S-55T previously registered in the United States (N824T).

Thus on February 24, 1972 Eisenhut contacted the Federal Office of Civil Aviation in Berne to discuss a number of administrative questions related to the import of the helicopter which was subsequently entered in the Swiss aircraft register on April 11, 1972 with the call sign HB-XDS.

This aircraft (built by Sikorsky in 1958 as S-55B s/n 55-1186) was shipped to Rotterdam at the beginning of May 1972. On May 7 it was flown to Switzerland by the pilots W.U. Eisenhut and Mike Zimmer.

It was checked at Belp/BE airport on May 15 by the inspectors of the Federal Office of Civil Aviation and allowed for commercial activities.

It seems that in addition to this aircraft there was the idea to convert other nine H-19D at Pilatus Aircraft Ltd in Stans/NW.

In the meantine on March 24, 1972 two S-55 arrived by truck in Switzerland from Italy where they had previously been in service with the Italian armed forces.

However in Switzerland the S-55T didn’t get the expected success. In that years where a significant number of projects relating to the construction of ski lifts, cable cars, aqueducts, huts, electricity and telephone lines, antennas, etc. were undertaken in the Swiss Alps, two new helicopters made their appearance: the SE 3160 Alouette III and the SA 315B Lama. Both, but especially the Lama, were likely direct competitors of the S-55T in terms of payload.

During that period the fleet of Heliswiss lacked a medium-size helicopter. The company employed light helicopters like the Bell 47 (payload 660/300 lbs/kg) and the Bell 206 Jet Ranger (880/400 lbs/kg) series and three Agusta-Bell 204B which had a maximum lift capacity of 3,300/1'500 lbs/kg payload.

For this reason Heliswiss decided to test the S-55T. However it was not long before the Swiss pilots realized that this helicopter wasn’t well suited to their need. For these reasons HB-XDS was forced to emigrate abroad to find new employment opportunities.

Heliswiss’ pilots and mechanics jokingly nicknamed the helicopter "old coffee grinder", "tractor" or "gros bourdon" (big bumblebee) when it was employed in the Swiss French-speaking region.

Between March and October 1973 HB-XDS flew in Spain on behalf of Helicsa for an offshore service in the Canary Islands. For this particular task the helicopter was equipped with emergency inflatable floats and a hydraulic winch. During this period there was an unlucky accident, fortunately without severe consequences. On August 9, 1973 while the helicopter was hovering in ground effect at the heliport of San Sebastian the gas turbine suffered an overspeed that forced the technicians of Garrett to rush to the scene to replace it.

The following year HB-XDS found a new job in Germany where it was employed for SAR duties on behalf of Süd Helicopter in the region of Munich.

In that period U. W. Eisenhut signed a contract for the sale of one of the two H-19D purchased in Italy. The Swedish helicopter operator Norrlandsflyg AB based in Gällivare was looking for a medium size helicopter, and the S-55T was a cheaper option than the Bell 205.

For this reason one of the two H-19D (s/n 55-1252) was transported from Belp to the Pilatus factory in Stans where the mechanics carried out the conversion. For the test flights the helicopter received the American registration N62540.

On March 15, 1975 this helicopter left Switzerland headed for Sweden where it received the new registration SE-HGZ. This aircraft served uninterruptedly for nearly thirty years: it made the last flights in June 2004. Then it was retired from service and put on sale.

After its return from Germany HB-XDS, despite its limited performances, was again occasionally used by Heliswiss for the transportation of building materials. It was based mainly at the heliports of Domat-Ems/GR and Gruyères/FR.

The opinion of a pilot

Among the pilots who flew the HB-XDS in Switzerland there were (among probably others) Jean-Michel (Mike) Zimmer, Jean-Pierre Füllemann, Georg Wedtgrube, Jean-Bernard Schmid, Walter Ulrich Eisenhut, Walter Tschumi and Ernest Devaud.

The latter during one of my interviews told me: "I remember well the flights with the S-55T HB-XDS. I flew with it during the period July-November 1975 when it was based temporarily at Gruyères/FR and where I was employed on behalf Heliswiss. The S-55T was quite easy to fly, but inadequate for operations in the Swiss Alps due to its limited performances, especially at high altitude. Moreover its large size and the four wheels landing gear limited its ability to land on sloping or uneven terrains or alps.

The S-55T had a slung load capacity comparable to that of a SE 3160 Alouette III (namely 1,650/750 lbs/kg), but the latter was more agile and efficient as well as more economical. Another problem was the fact that the S-55T had a limited downward visual and no mirrors, and therefore it was not very well suited for some delicate missions such as for example aerial assembly of antennas or pylons. There was of course a lot of space in the cabin, but we rarely took advantage of this feature.

Given its size there was also the problem of finding a space in the hangar. Among the various works carried out I remember the transportation of 70 tons of building material for the construction of a mountain hut in the Trême valley".

When it was used as an aerial crane the customed paid 27.-- Swiss Francs/min, a little less than the price charged today after more than forty years for helicopters with comparable performances!

In 1976 HB-XDS passed a large part of the year in Transair’s hangar at Belp due to lack of contract work. That is why it logged only thirty hours of flight.

On September 7, 1976, it took off from Domat-Ems/GR headed for Udine (Italy) where it was planned to be employed for supply flights in that region hit by a severe earthquake.

However shortly after the take-off the pilot Jean-Pierre Füllemann was surprised by a sudden loss of control attributed to a failure of the hydraulic system or a sudden turbulence. A rotor’s overspeed occurred and the pilot was forced to execute a precautionary landing near Davos/GR. The helicopter was then transferred to Belp by truck for a technical inspection.

In the meantime Norrlandsflyg, satisfied with SE-HGZ, decided to purchase a second S-55T along with the entire spare parts stock and the second H-19D imported from Italy.

During the five years spent in Switzerland HB-XDS logged a little over 350 hours of flight, not much considering that a commercial helicopter in Switzerland usually flies an average of 500 to 700 hours per year.

On March 9, 1977 “Delta-Sierra” was flown to Sweden where it received the new registration SE-HHY. On March 15, 1977 it was deleted from the Swiss aircraft register.

Unfortunately, on August 15, 1979 shortly after take-off this helicopter hit a power line and crashed into the lake Sitasjaure in the Sarek National Park located about 130 kilometers west of Kiruna. Sadly five of the six occupants lost their lives in this tragic accident.

Interesting links

Watch this video showing the S-55T in service with Pirate Wings at work → Link

HAB 01/2017