Mil MI-6 Hook - History and technical description

The Mil Mi-6 Hook is a heavy transport helicopter developed in Russia in the course of the 1950s. It has established many firsts: it was the first Soviet (twin) turbine powered helicopter to enter in production and for several years the largest, both for its size and for its load capacity. The Mil Mi-6 Hook also set 16 world records.

A tragic accident happened in 2002 marked the end of the career of this “flying heavy truck”. In April 1966 one of these aircraft was shortly tested in Switzerland.

The origins

The development of the Mil Mi-6 began in the first half of the ‘50s to meet the needs of the Soviet armed forces and those of the state-owned industries that were looking for a helicopter capable of carrying large payloads over long distances.

In those years, a period often known as the Cold War period, there were military and industrial projects scattered throughout the Soviet Union, even in remote areas such as the immense Siberian regions.

Having successfully completed the construction of the Mi-4 Mikhail Leontyevich Mil (1909-1979) accepted a new challenge and started designing a rotorcraft with a greater load-carrying capacity.

Mil was a brilliant aeronautical engineer at the head of one of the many OKB, acronym for Opytnoe Konstructorskoe Bjuro, thus experimental design bureau.

Despite the opinion of other Russian and international experts who recommended a twin-rotor configuration for large helicopters, the Russian engineer retained the single-rotor configuration for the new project.

The design work began in 1952. Following the initial specification Mil began working at a helicopter that was initially designed to carry a useful payload of 6 tons.

While the work on the original project was going on, the military set a new requirement: the increase of the payload to 12 tons. This obviously involved radical changes, one of which was the transformation of the aircraft into a twin engine.

Given the enormous power required, Mil decided to power the new helicopter with turboshafts which were lighter and more powerful than conventional piston engines.

The preliminary design was completed by the end of 1953. On June 11, 1954 the USSR Council of Ministers authorized the development of the large helicopter which was named as V-6 (where V stands for Vertolyot ie helicopter)

Despite its huge size and the technical complexity, the design, construction and fine tuning went fairly quickly. At the end of 1954 the project was in an advanced state of development. On June 1, 1955 a special commission approved the construction of the mock-up which was then followed by the construction of the first prototype.

Usually the various OKBs worked together. Each group of engineers was specialized in a particular sector. There were for example teams of experts working on the development of turbines, others in rotor blades or transmissions. Once the prototypes were completed the acceptance test program succesfully, mass production in the large state-owned factories located throughout the country began.

In October 1956 the first prototype of the Mil Mi-6 was basically completed with the exception of the main rotor, the manufacturing of which was lagging behind. Its assembly was carried out in a hangar in Zakharkovo near Moscow.

The first of five prototypes made the maiden flight on June 5, 1957 with test pilot Rafael Ivanovich Kapreliants (1909-1984).

Test flights continued throughout the summer.

The prototype wore an overall silver colour paint scheme with no markings other than a large red star on the fuselage. The first official photos of the huge helicopter appeared in the press in the autumn 1957. In this period the engineer Mil released a series of interviews during which he spoke of the development of the Mi-6.

Various were the difficulties in the development phase. According to information gathered, the greatest challenge was the design and construction of the main rotor blades.

The huge rotor head for the first time on a Russian helicopter was equipped with hydraulic shock absorbers.

The Mil Mi-6 sets new records

Since the early public flights the Mil Mi-6 attracted wide international interest: given its dimensions it could not have been otherwise! At that time, the Soviet aircraft established the first of a series of world records approved by FAI (the acronym for International Aeronautical Federation). On October 30, 1957 it carried an internal load of 12,000 kg (26'470 lbs) to an altitude of 2'432 meters (7'980 ft). Thanks to its extraordinary performance all the previous records were outclassed.

The second prototype was completed in February 1958. It differed from the first in being fully equipped in accordance with the original project, that is to say, it was fitted with two stub wings, a barycentric hook for external loads, an autopilot and other equipment.

Stub wings to offload the main rotor

Up to 1966, the 15.30 meters wings span stub wings (total surface of 35 square meters (376.5 sq ft), had variable incidence. Due to the asymmetrical main rotor downwash each wing had a different angle of incidence. In autorotation the wings shifted to lower angles of setting. However, it was found that the flying properties of the helicopter changed slightly when gliding using the setting angles designed for flight with the engines operating, and that the stability and manouvrability were almost identical.

Therefore, in order to simplify the design and increase operating reliability, the stub wings were fixed rigidly to the fuselage (the right one with an incidence of 15.45 degree, 14.15 degree to the left).

Not all Mil Mi-6 had stub wings. During heavy-lift operations the latter were in fact often removed to give the aircraft greater payload capability.

Moreover, in hovering and at low flight speeds, the downwash on the stub wings surface created a drag. In hovering this drag was 2% of the total weight of the helicopter, i.e., about 800 kg (1,764 lb.). Obviously an increase in speed also increased the lift. According to precise aerodynamic calculations the stub wings increased the rotor lift by 14% at a speed of 200 km/h, and by 19% at 250 km/h. At the max. speed of 300 km/h the stub wings offloaded the main rotor by 25%.

In 1958 the two prototypes were presented at the annual military airshow in Tushino near Moscow.

In the course of the years the Mil Mi-6 set new records. In June 1961 the American Helicopter Society awarded Mil’s OKB the Igor I. Sikorsky international trophy as the first helicopter to exceed 300 km/h (186 mph) in level flight.

During the month of September 1962 some Mi-6 piloted by Vasily Koloshenko, Rafael Ivanovich Kapreliants and Boris Karpovich Galitsky established 11 new world records.

On September 13, Kapreliants reached an altitude of 2'738 meters (8'985 ft) with a payload of 20'117 kg (44,350 lbs).

The Soviet armed forces were so much in need of heavy helicopters that a Government decision on putting the Mi-6 into production was taken long before the completition of the official acceptance tests were completed (December 1962).

The Mil Mi-6 was also faster than any other helicopter. On August 26, 1964 Galitski established near Moscow an absolute world speed record flying at an average of speed 340.15 km/h (211.35 mph) over a 100 km course speed w/o payload.

The Mi-6 was exhibited for the first time at the Paris Air Show in 1965 where it attracted vast attention.

NATO assigned the Russian helicopter the distinctive code-name "Hook".

On the basis of data collected, a total of 928 Mil Mi-6 were manufactured. The majority was used by Soviet armed forces. Apart from an initial batch of about 50 aircraft, the rest was built in State-owned factory 168 in Rostov-on-Don between 1957 and 1980.

Over the years, the Mi-6 was gradually improved. A new general utility version which was externally very similar to the predecessor but designated Mil Mi-6A appeared in 1971. It differed in having components with a greater operational life and a new avionics system. The original hydraulic system for example, was modified and incorporated into a single system.

The Mil Mi-6A was capable to lift a greater slung load (up to 9,000/19,840 kg/lbs ) and had a maximum takeoff weight increased to 44,000/97,000 kg/lbs.

New components were developed in order to increase the performance and service life.

More than 60 aircraft were supplied to the armed forces of several countries around the world but all under the sphere of influence of the Soviet Union. Among these were the following in alphabetical order: Algeria, Belarus, Bulgaria, China, Egypt, Ethiopia, Indonesia, Iraq, Kazakhstan, Laos, Peru, Poland, Russia, Syria, Ukraine, Uzbekistan, Vietnam and Zimbabwe. Export deliveries began in 1964.

During its long career which lasted more than forty years the Mil Mi-6 was used for military operations (for example in Vietnam, Afghanistan, Chechnya, the Caucasus) and was the protagonist of historical events such as the occupation of Prague in 1968 where several were employed to transport Soviet commandos to the airport of Prague.

Production ceased in the early '80s to give way to the more modern Mil Mi-26 "Halo", which is similar in general appearance to its predecessor but bigger and more powerful.

Civilian uses of the Mil Mi-6

The Mil Mi-6 was extensively used by Aeroflot for the construction of oil and gas pipelines, power lines, bridges, antennas and masts-laying, the transportation of heavy equipments and vehicles, the supply of geologists in remote areas, etc.

The Russian aircraft was a real air truck, strong, robust and versatile.

A special version known as Mi-6P was expressly developed for Aeroflot in 1965. It had airline-style interiors and accomodated up to 70-80 passengers. In this version the rear clamshell doors and cargo ramp were replaced by an identically shaped fairing which incorporated retractable airstairs on the centerline.

A version known as the Mi-6PZh was expressly developed to be used for fire-fighting operations. It could carry up to 12,000 litres of water in an internal tank and drop them trough a ventral nozzle.

It was supplemented with a tank for foaming agents, pumps, and two tubes hinged to the forward fuselage, with transverse stiffening rods in between like the rungs of a ladder and a common ‘mouth-piece’ at the rear. The pumps were lowered by means of cables and pulleys for taking on water in the hover; when stowed under the fuselage, the ‘mouthpiece’ rested in an aperture formed by the removal of the cargo ramp. The helicopter could also deliver to the site of fire six bag-type tanks holding 1.5 tonnes (3.307 lb) of extinguishing agent each, packed into a special net on a sling.

General technical description

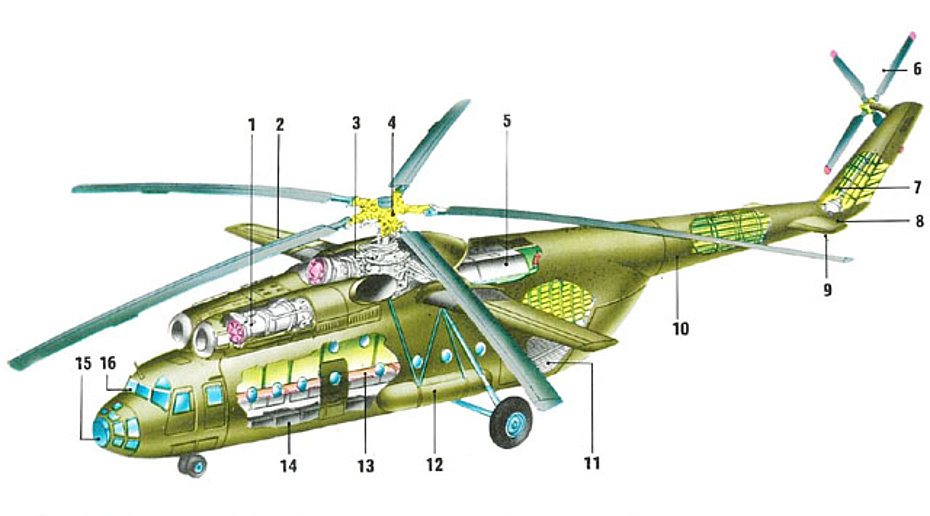

The Mil Mi-6 Hook is a multi-purpose heavy lift helicopter of a conventional design, ie with a single main rotor and an anti torque tail rotor. It was manufactured in several variants, each adapted for a specific use. However, the following description is general and refers to the basic Mil Mi-6 version.

The all-metal semi-monocoque fuselage consists of four sections: the nose, central, tail and tip beams. Materials used are mainly duralumin, aluminum alloys, magnesium alloys, titanium alloys and high-strength steel.

In the extensively glazed nose section of conical shape there is the the crew's cabin that usually comprised, in addition to the pilot in command (who sat on the left): a co-pilot, a navigator accommodated in the most advanced position, an engineer and a radio operator.

Some military Mi-6’s were equipped with a DShK 12.7 mm machine gun mounted in the nose handled by the navigator.

Access to the cockpit is through two lateral doors (jettisonable in the event of an emergency) with a ladder on the left side of the cabin and a third door on the right side.

On the right side of the navigator’s station (the latter has a small workstation and all the tools and equipment for all-weather navigation) there is and escape door. The navigator’s station is accessible either through this door, or from the cockpit through a passage placed between the pilot and co-pilot stations.

The lateral bulked windows of the cockpit improve visibility down and to the rear.

Given the size and technical complexity of the aircraft, pilot, navigator and engineer’s stations were provided with a lot of instruments grouped in a functional way. The flight controls are conventional.

Behind the pilot's seats there is a station for the flight engineer (or mechanic) and the one for the radio operator who sat in a small work station on either side of the aisle connecting the crew’s cabin with the cargo bay.

Alongside the usual instruments, the flight/navigation system included aids such as a short-range radio-altimeter, artificial horizons, gyro-compass, automatic radio compass and marker beacon. The system ensured all-weather blind flying and landings day and night. The directional gyro allowed navigational tasks to be solved when the helicopter flew in the Polar regions where magnetic and gyro-magnetic compassess were of no use.

The helicopter was provided with two radio sets: a communication set which ensured long-range two-way voice and key and short and medium wave communication, and a command set for VHF voice communication. There was also an interphone for intercommunication between crew members.

Access to the huge interior compartment (length 11.72 m, width 3.14 m and variable height from 2.64 to 2.01 m), was possible through two large hydraulically actuated clamshell doors and access ramps. The cargo compartment of approximately square section with frames, longerons and stringers structure has a floor stressed to 2,000 kg/sq metres. Features were added on the floor for special cargo tie-down rings. The Mi-6 could trasport inside its cabin bulky loads such as vehicles, equipments and arms up to a weight of 12,000/25,455 kg/lbs.

Loading immobile cargoes into the cabin was possible with the aid of an electrical winch and a cable hook with a driving power of 800 kg (1,764 lb.). To otain higher driving power, use was made of a pulley block system which was supplied as a standard equipment with the helicopter.

Beneath the floor containers for eight fuel tanks are found, (total capacity 8,150 litres or 2,153 USG) while the remaining three fuel tanks are placed in containers over the ceiling of the load-carrying cabin. Provisions were made for two external fuel tanks, each with a capacity of 2,250 litres (594 USG), which could be mounted on each side of the fuselage on special brackets.

When necessary, two additional identical fuel tanks could be installed inside the cargo cabin.

The automatic fuel-flow control system ensured such sequence of fuel consumption from the tanks at which the centre of gravity position shift was the minimum.

The turboshafts, main reducer and fuel compartments were equipped with a fire extinguishing system which operated automatically in response to signals from heat sensors or manually.

The cargo cabin with rounded panoramic windows is equipped with fold-up type seats along its sides. When necessary there were additional seats which could be installed in the centre of the cargo cabin. Thus the helicopter could easily be converted to carry 70-80 passengers. In this case, addional cargoes were placed in the aisles.

However, it is reported that in emergency situations the helicopter trasported as many as 150 people.

The helicopter was equipped with an external sling system. The sling cable whose lower end terminates in a hook has a special tip and its upper end which is held in the sling lock. The lock was operated by a hydraulic jack. The Mil Mi-6 was able to lift underslung loads up to a weight of 8,000/17,635 kg/lbs (Mi-6A 9,000/19’840 kg/lbs).

Some aircraft were equipped with an electrical winch lowered through the central cargo floor hatch used for example to load and unload small cargoes (500/1,100 kg/lbs lift capacity) or people during rescue missions.

1 turboshaft - 2 main rotor blade - 3 transmission - 4 rotor head - 5 cargo compartment - 6 tail rotor - 7 tail rotor pylon - 8 horizontal stabilizer - 9 tail bumper - 10 tailboom - 11 access ramp - 12 auxiliary fuel tank - 13 pax seats - 14 internal fuel tank - 15 navigator cabin - 16 pilots cabin

Simplicity in maintenance

To facilitate servicing and operation of the helicopter, especially in out of airfield conditions, provision were made for a number of devices and units.

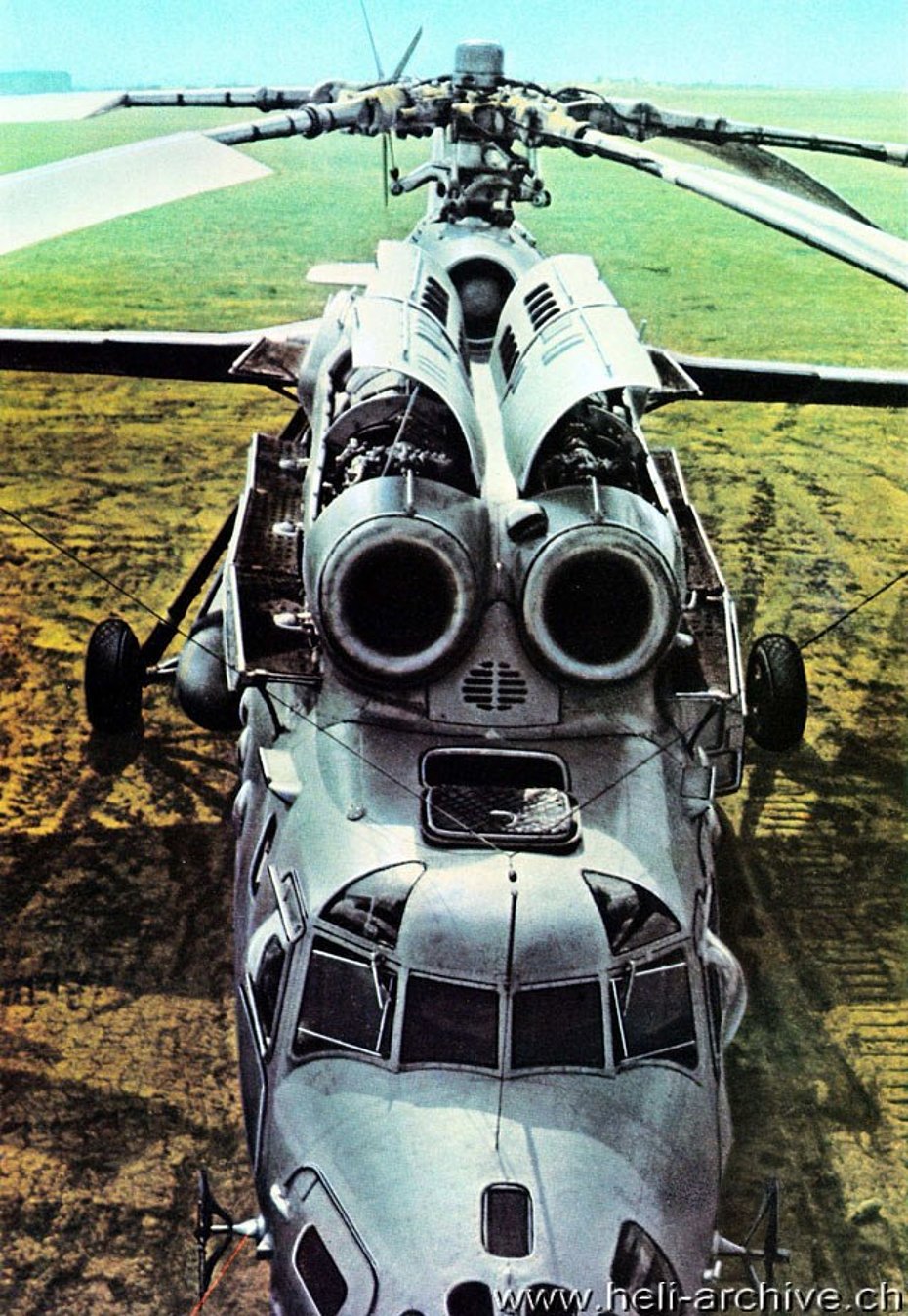

Therefore, the engines, the main gear box compartment, the swash plate and the main rotor hub could be inspected and serviced without special ground equipment, from the side panels of the engine cowlings, which were operated by hydraulic jacks and when open formed convenient service platforms. Access to these platforms was possible with the use of a ladder or through the hatch in the cabin of the crew.

Behind the clamshell doors enclosure, the tail boom assumes again a conic section and is joined to the centre fuselage by bolts at the end frame. It houses the tail rotor transmission shaft, tail rotor control cables, the stabilizer attachment, avionics and electric cables.

The tail rotor support acts as vertical stabiliser and carries the AV-63B variable pitch four blades tail rotor.

The tail rotor is protected against shocks by a tail bumper.

The Mi-6 helicopter carries a horizontal stabilizer (surface 4.87 sq meters) which could be controlled in flight to provide the necessary manouvrability and stability. The variable angle (from +5 to -13 degrees) of the stabilizer is combined with the "pitch-gas" lever: when the lever was moved upward, the angle of the stabilizer increased while when moved downwards, it decreased.

Rotors and transmission

The Mil Mi-6 has a 35 meters diameter five-blades fully articulated main rotor, a 6.30 meters four-blade tail rotor and a conventional transmission. The main reduction gearbox drives tail rotor, fan, generators and hydraulic pumps. Intermediate reduction gearbox is fitted with special fan.

The axis of main rotor is tilted 5 degrees forwards.

Early models had a main rotor with trapezoidal blades, but in 1965 new rectangular blades with a constant chord of 1,000 mm were introduced (each blades weighs 715/1,576 kg/lbs).

The load accepting element of the main rotor blades is a steel longeron, an all-metal cold-rolled tube of variable cross section 15,610 mm in length which is sealed and has a system for signaling damage. The blade frame, consisting of 20 sections, is fastened to the longeron by special fastening units. Each section consists of a nose and a tail portion and transmits the aerodynamic forces to the longeron. When the blades bend, the sections do not interact with each other, merely transmitting the aerodynamic and inertial forces directly to the longeron.

The tail portion of the blades has a honeycomb filler. They also have a geometric twist.

Due to its design specifics, rectangular blades had better aerodynamic qualities and generated a greater lift.

The rotating speed of the main rotor was around 120 rpm (a variation between 113 and 130 rpm was admitted).

Continuous improvements resulted in a better aerodynamic blade efficiency. Moreover, their service life was considerably increased from 50 hours in 1957 to 1,500 hours in 1971.

The 6.30 meters in diameter tail rotor has four blades made of plastic-impregnated wood built around steel spars.

The tail rotor rotated with a speed between 637 and 678 rpm. Each tail rotor blade weighs 60/132 kg/lbs, while the complete tail rotor weighs 570/1256 kg/lbs.

The total weight of the lifting rotor is 6,825/15,046 kg/lbs, or 16% of the maximum take-off weight of the helicopter.

De-icing system

The helicopter had a system signaling the beginning of icing. The electro-thermal de-icing system made it possible to perform prolonged flights under severe icing conditions.

The heating elements of the system were located in the main and tail rotor blade tips and on the nose section of the engine intakes.

The glazing of the pilot’s cabin and front window of the navigator’s cabin were also heated electrically. The degree of heating by the main and tail rotor de-icing elements depended upon the outside air temperatures and was controlled by changing the frequency of the operating cycles of these elements.

The anti-icing devices were powered by 280V three phase AC. This current was supplied by two SGS-90/360 generators. The compressor guide vanes were air-heated.

According to the information gathered, the tail rotor of the early Mil Mi-6 was de-iced by a system using an ethyl alcoholic/glycerine mixture contained in a 28 litres tank.

Landing gear

The helicopter has a tricycle landing gear with oleopneumatic shock-absorbers. The nose leg is steerable and carries two non-brake wheels measuring 720 x 310 mm. The main legs are fitted with brake wheels 1325 x 480 mm. The two (low pressure and high pressure) chambers in the main undercarriage shock-struts ensured smoth operation of the shock absorber and dampening of oscillations at a small undercarriage loading. The high pressure chambers of both shock struts were interconnected though an overflow system equipped with a spring damper. The damper permitted dampening of helicopter oscillations at the full undercarriage loading.

The combination of the two-chamber shock strutted with the overflow system eliminated almost completely ground resonance in taxiing, landing runs and other movements on the ground.

Only early production models were equipped with main landing gear wheels fairings.

Powerplant

The two turboshafts are located side by side above the cabin (a feature nowadays almost universally adopted) in front of the rotor shaft and are tilted downward at 5 degrees in relation to the longitudinal axis. The engines are fastened to the fuselage through brackets and adjustable uprights with rubber shock absorbers.

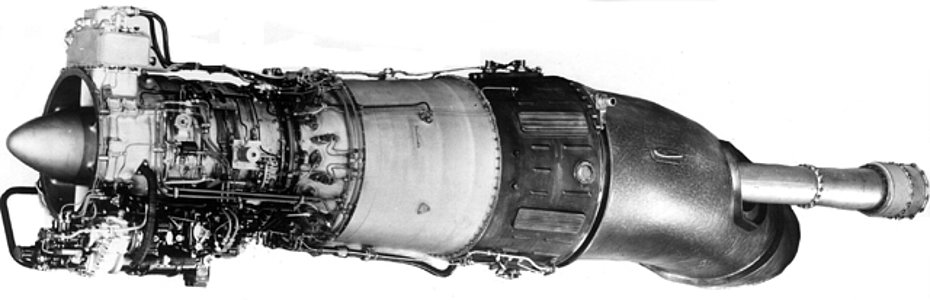

The first three prototypes were powered by two Soloviev TV-2VM each with a maximum take-off power of 4,100/5,500 kW/hp and a continuous power of 3'457/4'700 kW/hp.

These engines were replaced with the Soloviev D-25V of equal power but shorter and lighter (each weighing 1,243/2,740 kg/lb.). This led to various modifications because the new turbines rotated in the opposite direction. The first Mil Mi-6 powered by the new Soloviev D-25V was delivered in the spring 1959, even if acceptance tests were not yet completed. When the third prototype began test flights the first two were also modified.

The turboshaft (manufactured in two series, the second series had compressors that rotated faster) were equipped with a system for automatic start.

The engine had 1,800 hours interval between major maintenance work.

With a take-off weight of 40,000/88,183 kg/lb. in cruise flight at an altitude of 500 metres (1,640 ft) and with air temperature of 17°C the hourly fuel consumption indicated by the manufacturer for the Mil Mi-6 was about 2,450 litres (2,000 kg) with rectangular blades, and 2,700 litres (2,200 kg) with trapezoidal blades.

The helicopter was equipped with flight and navigational instruments, radio equipment and autopilot.

Initially it was equipped with an AP-31V three-channel autopilot which had been tested on the Mi-4. However, this equipment was judged unsatisfactory and therefore from 1962 onwards it was replaced by the improved AP-34V. As distinct from its predecessor, the AP-34V was incorporated into the control circuit, rather than in parallel, which considerably eased the piloting effort. The autopilot ensured the stability of the helicopter in yaw, roll, pitch and altitude.

Electrical instruments, radio equipment, and all electric mechanisms were fed with 27V current. The main DC sources were two 12kW starter-generators.

In the event that both generators failed, the batteries ensured operation of the required electrical equipment for about 30 minutes.

The helicopter was also provided with an AC 360V three-phase current system. The AC sources were two generators 90kVA each. This system was intended for feeding electro-thermical de-icing system and some radio equipment items operated on AC current.

Early Mi-6 did not have the APU and this caused starting problems especially in extreme weather conditions. This was extremely important, especially in remote areas. Therefore to overcome such inconvenient malfunctions they were equipped with an Ivchenko AI-8 74.6/100 kW/hp 24 kW trailer mounted generator. From 1967 onwards the APU was permanently installed inside the left clamshell door.

The current supplied by the auxiliary generator allowed the operation of electric and hydraulic mechanisms. Furthermore, personnel could perform the necessary tests, operate the winch, the radio system and in the event of a refueling requirement, pump and of course each tool or electrical equipment.

General performance

The table resumes the performances at the MTOW:

|

Vne |

300 km/h |

186 mph |

|

Cruising speed |

250 km/h |

155 mph |

|

Range with 8'000 kg payload |

620 km |

385 miles |

|

Practical service ceiling |

4'500 m |

14'770 ft. |

|

Service ceiling |

5'000 m |

16'410 ft. |

|

Hovering ceiling IGE |

1'000 m |

3'280 ft. |

With the auxiliary fuel tanks and a commercial load of 4,500/9,920 kg/lb. the maximum range was 1,000 km.

With a takeoff weight of 42,500/93,625 kg/lb. the maximum range was reduced to 220 km.

In ISA conditions and with a total weight of 37,400/82,450 kg/lb. the helicopter could hover out of ground effect (OGE) at 1,000/3,047 m/ft altitude. The mass of the helicopter had to be reduced to 33,500/73,850 kg/lb. to hover OGE at an altitude of 3,000/9,845 m/ft.

In ISA conditions and with a takeoff mass of 38,800/85,538 kg/lb. the initial rate of climb at sea level was about 360/1,180 m/ft min. The best rate of climb was obtained with an indicated airspeed of 140 km/h.

The theoretical ceiling of the Mi-6 helicopter was 5,000/16,410 m/ft and the practical ceiling was 4,500/14,770 m/ft. With a maximum weight of 42,500/93,695 kg/lbs, the maximum flying altitude was limited to 3,000/9,845 m/ft (rectangular blades) and 1,500/4,920 m/ft (trapezoidal blades).

The Mil Mi-6 in flight

The Mi-6 proved to be very stable and it was a pleasure to fly it at cruising speed. However at slow speeds undesired vibrations appeared. Moreover, at its max takeoff weight the helicopter was underpowered. Therefore pilots, when possible made rolling takeoff and roll-on landings. These flying techniques increased the max takeoff weight and overcome vibrations problems quicker.

The Mi-6 differred from its predecessor in its piloting technique. It reacted in fact slower to pilot’s input.

Many complaints were caused by the main hydraulic system, the AP-31V autopilot and the D-25V turboshafts which were prone to the dangerous overspeed problem which could literally disintegrate the engine with tragic consequences. This problem was solved with a system which controlled the engine RPM and automatically shut the engine down.

Thanks to continuous improvements, the Mi-6 became a reliable aircraft well liked by its crews and capable to fullfill its missions succesfully.

Aeroflot pilots logged considerably more flight hours per year than their military colleagues. Civil pilots were often engaged in the transportation of large diameter steel tubes measuring each more than 30 meters in lenght (100 ft) and weighting nearly 7 tons (about 15,400 lb.) used for the construction of oil or gas pipelines.

Dimensions, weights, payload

The main rotor of the Mil Mi-6 Hook has a diameter of 35.00 m (main rotor disc area 962 sq meters), while the tail rotor has a diameter of 6.30 m.

The fuselage has a length of 33.18 m, while the height measured to the mast is 6.71 m.

The standard empty weight of the aircraft was about 27,240 kg (60,050 lb.). The max weight for vertical takeoff was 42,500 kg (93,700 lb.) with internal load in the cabin and 37,500 kg (82,675 lb.) with slung loads.

The Mil Mi-6 could carry internally a max payload of 12,000 kg (26,455 lb.) or slung loads up to 8,000 – 9,000 kg (17,637 – 19,841 lb.) depending on the version.

The Mi-6A had a max takeoff weight of 44,000 kg (97,000 lb.).

The Mil Mi-6 Hook in Switzerland

In his book "Blick zurück - Mein Leben als Flieger im letzten Jahrhundert" (A look back – My life as pilot in the last century) author Walter Tschumi, former chief pilot of Heliswiss wrote in detail the circumstances in which the Mil Mi-6 arrived in Switzerland.

In the '60s, an attaché of the Russian consulate named Golischkin repeatedly visited the offices of Heliswiss in Bern in order to advertise the employment of Russian helicopters.

In March 1966 Golischkin informed Heliswis that a helicopter Mil Mi-6 would be transferred in the south of France to be used on behalf of civil defence (Protection civile) as a fire-fighter. At the same time the Russian attaché handed out some brochures that contained some technical information on the helicopter. It was quite evident that the Russian helicopter was too large for the needs of Heliswiss.

However, the board of directors accepted the insistent proposal of Golischkin to test the Mil Mi-6. Therefore Heliswiss prepared a program that included the transport of one of the two new cabins of the Schilthorn cable car (weight 5,000/11,800 kg/lb.), the transport and the positionning of 40 concrete masts in Herisau weighing each 7,000/15,430 kg/lb. and last but not least the transportation and installation of a truss weighing 5,000/11,020 kg/lb. for a new building of the Federal Office of Metrology located in Wabern near Bern.

Heliswiss spent several days to obtain countless permissions from civil and military authorities. It should not be in fact forgotten that those were the years of the so-called Cold War.

By the end, all burocratic problems were solved and the Mil Mi-6 obtained the green light and was officially authorised to enter into Swiss territory.

However, the Swiss Army obliged the Russian helicopter crew to follow precise routes in order to avoid installation protected by "military secrecy".

The Russian helicopter arrived in Bern-Belp from Nice (France) in the early afternoon of April 18, 1966. At the controls of the aircraft registered CCCP-06174 there were pilots Vasily Koloschenko and Yuri Alexandrovich Garnaev, another famous test pilot as well as "great hero of the Soviet Union". With them there were also an engineer, a radiotelephonist, a navigator, a load master, a group of 16 flight assistants, an interpreter, Heliswiss chief-pilot Walter Demuth and finally a member of the Communist party who was always anxious because he probably carried on his shoulders the responsibility of the entire helicopter program.

The following day Tschumi flew with the Russian pilots to construction sites for a reconnaisance flight.

Tschumi had the impression that the Russian crew was far from being enthusiastic with its hard tasks but obviously it could not publicly express its discontent.

In the following days men and loads were prepared carefully. Given the enormous downwash created by the rotor (someone described it like an hurricane) it was necessary to secure the construction sites area.

Finally on April 21 everything was ready. The helicopter took off from Belp and flew to the Lauterbrunnen valley. After the short trip it landed in the small rural village of Stechelberg where the cable car cabin of the Schilthorn was ready to be airlifted.

The transport of the cabin weighing 5,000/11,022 kg/lb. was executed without great difficulty.

However while the helicopter was hovering with the heavy cabin suspended to the barycentric hook, the roofs of some barns were partially unroofed. Fortunately no one was injured! In a matter of minutes the load was transported to its destination.

The rapresentative of the Communist Party was greatly relieved but didn’t want to go further. "You have seen how it works, you don’t need other demonstrations, it is not necessary, is it?" he insistently repeated, hoping that someone would listen. However, the crew of the Mi-6 proud of the result continued its challenging program.

After that first aerial transportation one thing was already clear: Heliswiss would have never been able to start the activity with a helicopter of such dimensions. The Russian helicopter was simply too large for the need of Heliswiss customers. Moreover, the helicopter company based in Belp was confronted with many difficulties (lack of financial resources was on the top of the list).

On April 23 Tschumi had the opportunity to fly as "co-pilot" with Koloshenko who had invited him for the flight to Herisau (Canton Appenzell Ausserrhoden). Tschumi was surprised by the huge space in the cabin. "The impression was to be on board of a large bus" he wrote in his book.

The helicopter landed in a field and slowly began to sink under its its enormous weight. To try to remedy the problem at first were laid in metal grids used in military airports, but even these were too weak. The problem was finally solved with the laying of massive wooden beams.

This was another inconvenient connected with the use of this helicopter.

Apparently the Russian pilots installed the concrete pylons without major problems, although it took a bit longer than expected.

On April 24, the helicopter transported a truss weighing 5,000/11,022 kg/lb. destined to a new building belonging to the Swiss Federal Institute of Metrology situated in Wabern near Bern. The helicopter hoovered for 20 minutes above the building, but even this delicate work was completed without major problems, although men working on the roof were described by Tschumi as sailors in the middle of a hurricane.

The next day the Mil-6 was presented to the Swiss Army. During the presentation, it took-off with an internal payload of 11 tons.

At the end of the test flights the Russians offered the chance to buy the helicopter with a series of spare parts for 7 million Swiss francs.

For the reasons already mentioned Heliswiss kindly refused the offer.

The "Helvetic tour" of the Mil Mi-6 CCCP-06174 ended with a dinner and it seems that the people who were present that evening still remember it! The Russians (but I imagine the Swiss too) celebrated the completition of their challenging job by opening various bottles of vodka.

The Mil Mi-6 left Switzerland two days later after completition of the last customs formalities at the airport of Altenrhein.

A tragic epilogue

The following year, the Mil Mi-6 CCCP-06174 which was in the meantime modified to be employed as a "flying fireman", arrived in France to be employed during the summer season as a firefighter with the Civil Defence.

On 6 August 1967, during a firefighting operation, the helicopter hit the wires of a power line in Ensues-La Redonne, near Marseille and crashed.

In the tragic incident (someone affirm that a sabotage was the cause of the incident) all the nine occupants including pilot Garnaev lost their lives.

The end of the career of the Mil Mi-6

On July 10, 2002 a tragic accident occurred in the Taymyr Peninsula (north of Central Siberia). In that accident which involved aircraft registered RA-21074 on behalf of a geological expedition 21 people lost their lives (5 crew man and 16 passengers).

Consequently the Interstate aviation Committee (IAC), institution that manages and oversees the activities of civil aviation in the Commonwealth of Independent States, consisting of 10 of the 15 republics of the former Soviet Union, decided to revoke the type certificate of the Mil Mi-6 series.

Interesting facts…

Several Mi-6s were abandoned in the village of Rassokha in a graveyard of vehicles and equipment contaminated by radiation after the Chernobyl nuclear disaster of April 26, 1986. In the days following the accident several large helicopters were employed to pour thousands of tons of sand and boron on the reactor debris. The sand was to stop the fire and columns of radioactive vapors and additional releases of radioactive material; the boron was to prevent additional nuclear reactions.

Among the most delicate mission assigned to Mi-6 crews there was the transportation of nuclear warheads from the deposits to the launch sites and airfield where the missile strike aircraft were deployed.

The flying cranes Mi-10 and the Mi-10K are derived directly from the Mi-6. The Mil Mi-26 Halo is an evolution of the Mi-6 and actually the largest helicopter in service in the world.

Interesting videos

Here is a short list of videos found on youtube:

https://www.youtube.com/watch?v=EE7nS4LqKOs

https://www.youtube.com/watch?v=-6Jk5cD547o&list=PLtN068P-iOyNoUDpQh00wpTVCFsDXSglv&index=3

https://www.youtube.com/watch?v=f_8RnKqxPBo&index=17&list=PL2j0YGJt-ljWFJ5p7iVyPQkoB226zRCPO

https://www.youtube.com/watch?v=c2PpxzvMcbE&list=PL2j0YGJt-ljWFJ5p7iVyPQkoB226zRCPO&index=26

https://www.youtube.com/watch?v=QbpOHHmb1xU&index=28&list=PL2j0YGJt-ljWFJ5p7iVyPQkoB226zRCPO

Recommended Books

Mil's heavylift helicopters Mi-6/Mi-10/V-12/Mi-26 written by Yefim Gordon, Dmitriy and Sergey Komissarov (ISBN 86 780 1 206 3) is a highly recommended book for all helicopter fans who desire detailed information on these models.

HAB 12/2014