Bristol 171 Sycamore - History and technical description

In England the Bristol Type 171 was the first helicopter to be granted a civil certificate of airworthiness and also the first to be manufactured in series.

By autumn 1944 it had been developed by a team of technicians led by Raoul Hafner (1905-1980), a brilliant Austrian designer and helicopter pioneer who moved from Austria to England in the early 1930s of the twentieth century to pursue his dream of vertical flight.

The first prototype flew in 1947 and the first aircraft entered service for military and civilian tasks by the early 1950s.

Origins

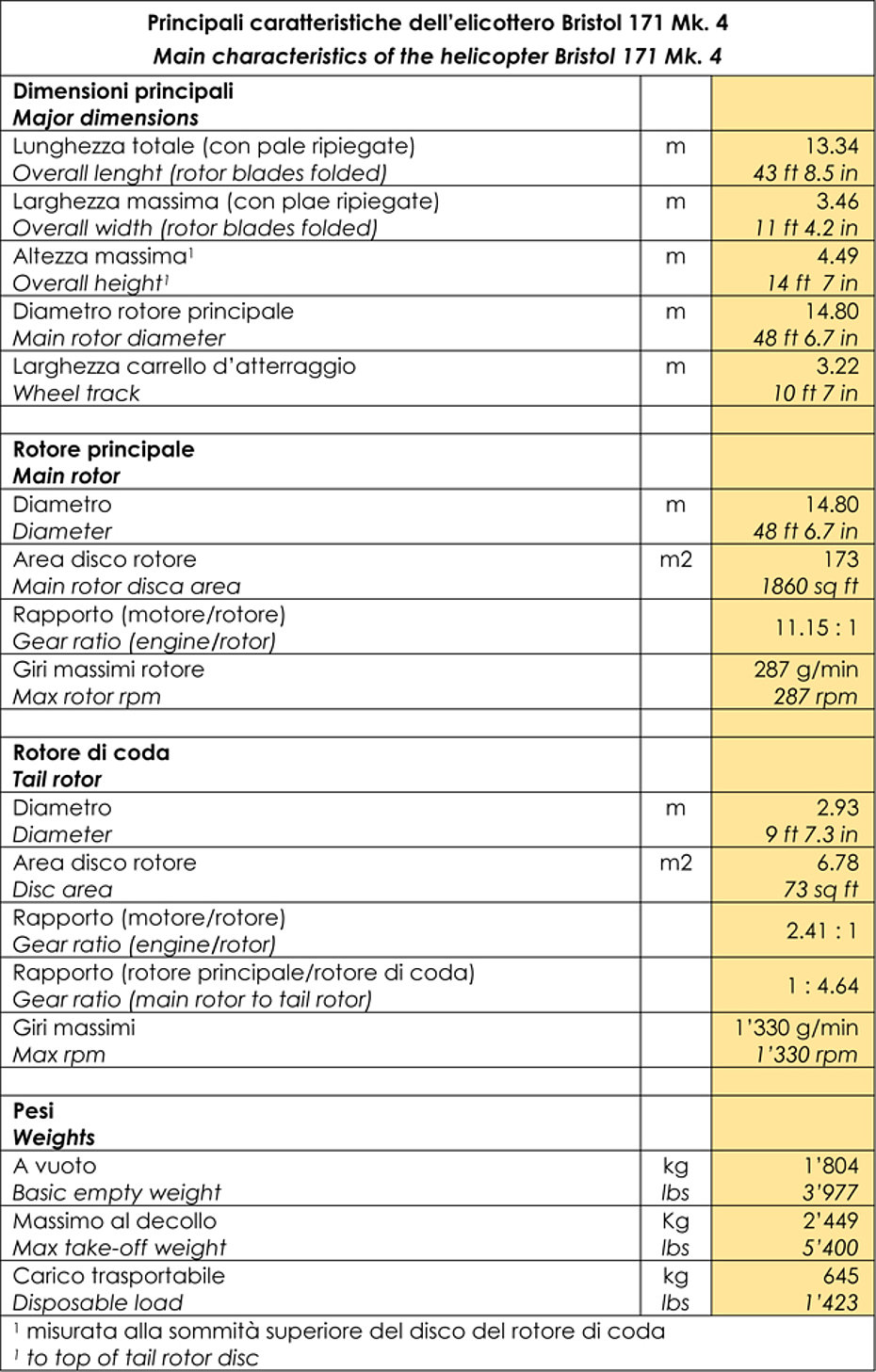

Hafner’s interest in the rotary-wing dates back to 1929 when, along with his friend Bruno Nagler, he started in Austria the construction of helicopter known as the Hafner R. I “Revoplane”. Built in Vienna, this model figured a three-blade main rotor with a cyclic and collective pitch control driven by an ABC Scorpion 22/30 kW/hp engine.

The helicopter was fitted with a pair of controllable vertical surfaces that should have, at least in the intentions of the designers, act as anti-torque control. This model was followed a year later by the Hafner R. II powered by a more powerful Salmson 9 ADr 33.5/45 kW/hp. Even with the R. II, which was essentially an improved version of the predecessor, Hafner was only able to make short jumps using the kinetic energy of the rotor.

In 1932 the Austrian manufacturer, who since 1930 received the financial support from Jack Coates, a rich Scotsman who made his fortune in the cotton industry, at the latter's request moved the R. II to the airport of Heston (England) to continue tests.

In 1934 seeing the scarce results obtained during the flight tests (for the chronicle the Hafner R. II is now preserved at "The helicopter museum" of Weston-super-Mare) Hafner took the decision to temporarily abandon the construction of helicopters and devote himself to the design and construction of a gyroplane known as the Hafner A.R. III (AR designation stood for Auto Rotation). During those years Hafner lodged several patents related to helicopters or gyroplanes designs in Austria, England and in the United States. Some were (and are still) registered in his name, others along with Bruno Nagler and Walton Victor D'Arcy Rutherford who was, it is assumed, a new financier.

The Hafner A. R. III made its maiden flight in September 1935 at the aerodrome of Heston piloted by Captain VH Baker. This aircraft according to reports and articles of that period proved good flight characteristics. Therefore Hafner decided to establish the A.R. III Construction Company based in Denham and planned its construction in series.

The small one-seater was also able to perform the so-called “jump takeoff”. During this maneuver the pilot accelerated the rotor to high RPMs with very low pitch. Then the drive was disengaged, and the rotor pitch suddenly increased. The aircraft jumped in the air up to 4-5 meters, using the stored energy, and then continued to fly in autorotation.

However the kinetic energy was sufficient to make a leap over an obstacle of some meters high in the immediate vicinity of the take-off point like for example a row of cars. This technique indeed, as well as presenting some risks, was not of much utility. More interesting were in contrast the general flight characteristics and some innovative technical solutions.

In the gyroplane designed by Raoul Hafner the three blades were allowed a restricted degree of freedom in pitch, being attached to the hub hinge by relatively thin tie-rods which the pilot’s control could easily twist sufficiently to give the necessary pitch variation. Above the rotor head there was a three-legged spider linked to the blades roots. Bodily vertical movement of the spider caused by the pilot’s control, increased or decreased the pitch angle of all three blades, while tilting the spider axis caused the blades to perform a cyclic and differential incidence variation. One objective of attaching the blades to the head by tie-rods and tilting the spider only instead of the entire rotor head was to reduce the load on the pilot’s control stick. Hafner A.R. III was said by pilots to be very light on the controls, and this was another characteristic very much appreciated by the pilots.

With the outbreak of World War II Hafner, who was still at that time an Austrian citizen, was temporary forced to suspend his aviation activity which he resumed only after obtaining British citizenship. During the war Hafner (now Mr. and no longer Herr Hafner) designed and built some autogyros known as the "Rotachute" and "Rotabuggy". However the advent of large gliders towed by aeroplanes put to an end Hafner’s unsuccessful experiments and consequently he resumed work on the design of a new helicopter.

The birth of the Bristol Type 171

The Bristol Aeroplane Company, originally known as British and Colonial Aeroplane Company, was one of the first (it was founded in 1910) and the most important manufacturer of airplanes and engines in the United Kingdom.

This society like others such as for example the historical Cierva (absorbed by Saunders-Roe in 1951), Westland, Fairey and much later Percival took the challenges and opportunities that the helicopter apparently offered and thus contributed to the creation and subsequent development of a new sector of the aviation industry.

Unlike Westland who decided to manufacture the Sikorsky S-51 under license, limiting at least from a technical viewpoint the possible risks of failure, or Fairey and Cierva who instead chose to build prototypes of radically new design (Fairey FB-1 Gyrodyne Cierva W.9 respectively), which, however, did not proceed beyond that stage, Bristol chose a third alternative, i.e. the design of a new helicopter but of standard configuration or with main and tail rotor.

During 1944 Bristol began to organize its Helicopter Division with the aim to build a four-seater helicopter in order to meet the specification E.20/45 issued by the Ministry of Supply.

Because of his extensive experience in the rotary-wing field, Raoul Hafner was chosen as project manager. To beginn with his team of technicians studied in detail the construction and flying characteristics of the helicopter Sikorsky R-4B known in the UK as the Hoverfly I.

Construction of the new helicopter, which received the designation of Bristol Type 171 Mark 1, commenced shortly after but for various reasons proceeded slowly.

At their facility in Filton, Gloucestershire county, the Bristol’s technicians built a series of test beds to examine the behavior and characteristics of the different components.

One of these installations was for example used to observe the functioning of the main rotor which was driven by a powerful electric motor, others to measure the levels of the vibrations, the balancing of the blades, or the behavior of the building materials. Thanks to these installations and equipment it was possible to accumulate many operating hours on each single component. The latter were then assembled so that the helicopter was ready for the first tests which began on May 8, 1947 with the helicopter fixed to the ground.

The first of two prototypes registered VL 958 made its maiden flight July 27, 1947 in Filton piloted by Alan Henry Marsh, an expert pilot who had been among the very first helicopter pilots in the UK. Next to him there was Eric Swiss, who later became chief-pilot of the whole test-flight program.

Unmistakable lines

The Bristol Type 171 Mk. 1 was an aircraft of classical configuration with tricycle landing gear. The characteristic that made it instantly recognizable was the long tail boom tilted down that held the three-blade tail rotor, and the unusually short shaft driving a three-blade fully articulated rotor.

The first two prototypes (the second registered VL 963 flew in February 1948) were powered by the nine-cylinder radial engine Pratt & Whitney Wasp Junior R-985-AN-1 with a maximum take-off power of 336/450 kW/hp.

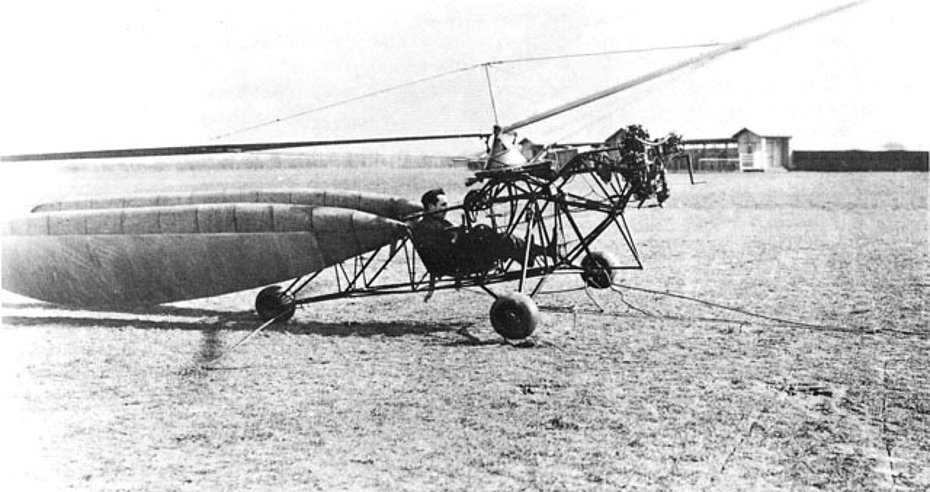

The incidence of the rotor blades manufactured by the firm H. Morris & Co. of Glasgow, was controlled by the same mechanism developed by Hafner for the autogyro A.R. III.

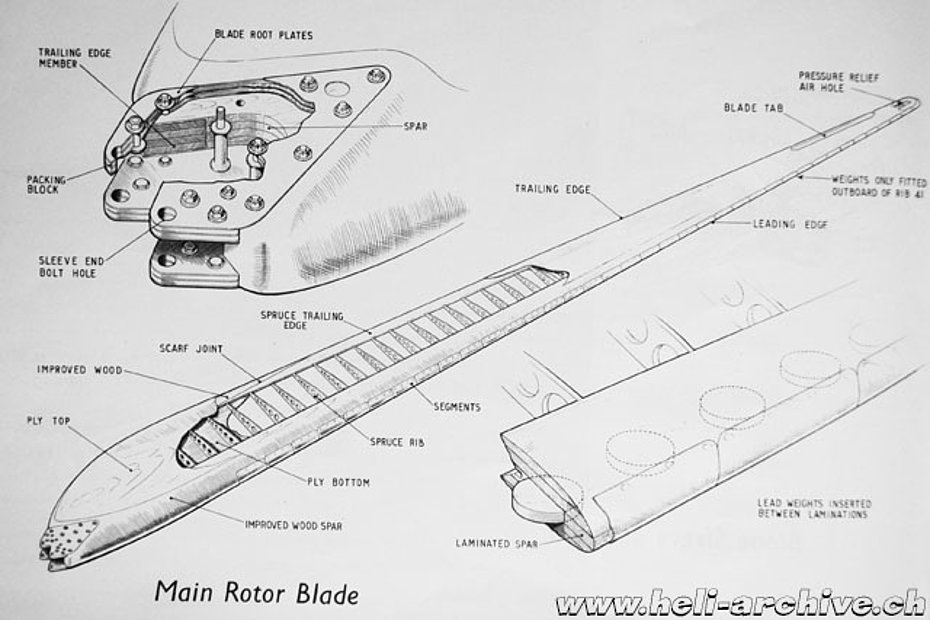

The construction of the main rotor blades and tail rotor was strongly influenced by the experience made earlier on autogyros and some technical solutions discovered on models captured from the Germans.

On May 26, 1949 the second prototype of the Bristol 171 Sycamore Mk. 1 received the first certificate of airworthiness issued by the British authorities and received the new civil registration G-ALOU. That same day, piloted by Eric Swiss, it also became the first British-designed helicopter to fly across the English Channel.

On September 29, 1948 prototype VL 958 took part in a speed race. The organizer’s intention was to deliver in the shortest possible time a greeting card sent by the Mayor of London to the Mayor of Paris. A relay consisting of two helicopters and a jet delivered the message in the record time of 46'29". Evidently the e-mail era was still far away!

The first two prototypes were followed by a new version known as Bristol 171 Mk. 2, which was powered by the new British-made 404/550 kW/hp Alvis Leonides LE 21 HM engine to specification E. 34/46 issued by the Ministry of Supply.

The new prototype registered VW 905, made its first flight on September 2, 1949 piloted by Eric Swiss and differed substantially from its predecessors mainly by the fact that the engine was installed horizontally with the crankshaft running vertically.

This solution eliminated the lower gearbox, and not only saved weight but also made the engine more accessible for inspections and repairs.

The next day, while Swiss was about to take-off for a new test flight, suddenly the wooden blades of the main rotor disintegrated. By chance nobody was hit by the debris, but this accident put the development project back some months.

As we will learn, the construction of the blades caused much later some serious accidents.

The availability of the more compact Alvis Leonides LE 21 HM engine (about 20 cm shorter) and with pumps and accessories such as the generator, vacuum pump, etc. driven by the main gearbox and not by the engine (thus functioning also in case of engine failure), led to the construction of a new version known as Bristol 171 Mk. 3. This model also incorporated other changes such as for example the relocation of the instruments, the adoption of rear sliding doors, a shortened nose to improve visual and the possibility of transporting three passengers in the rear seat thanks to increased cabin width.

By 1949 this version was the first to be built in series. Bristol also developed the Mk. 3A version which had a more spacious luggage compartment in order to meet the needs of British European Airways (BEA) who ordered two aircraft mainly employed for the transportation of passengers.

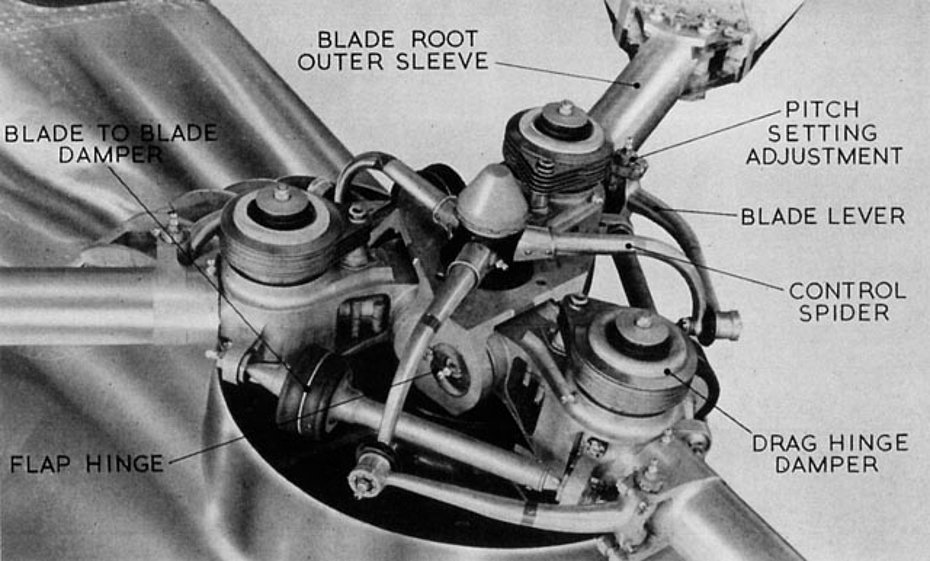

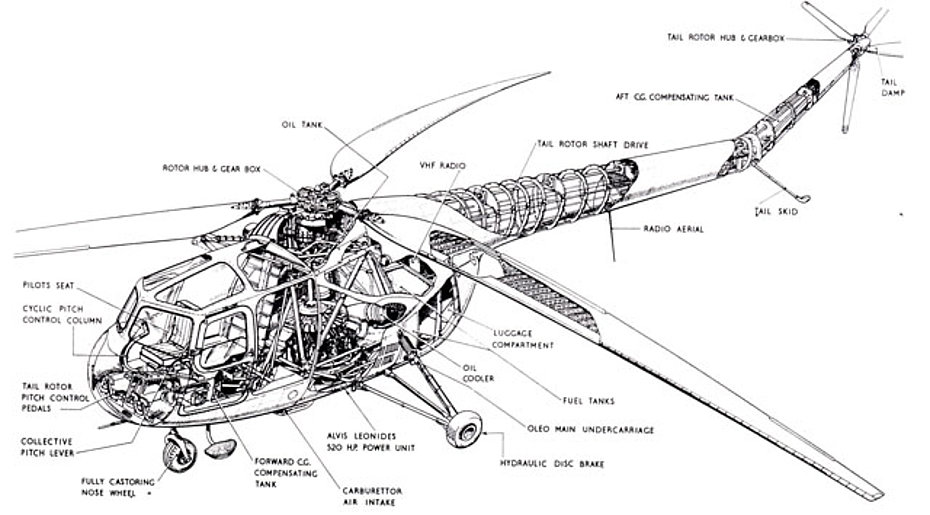

By the end of 1952 Bristol developed a new model known as Bristol 171 Mk. 4 which was the main version manufactured in series.

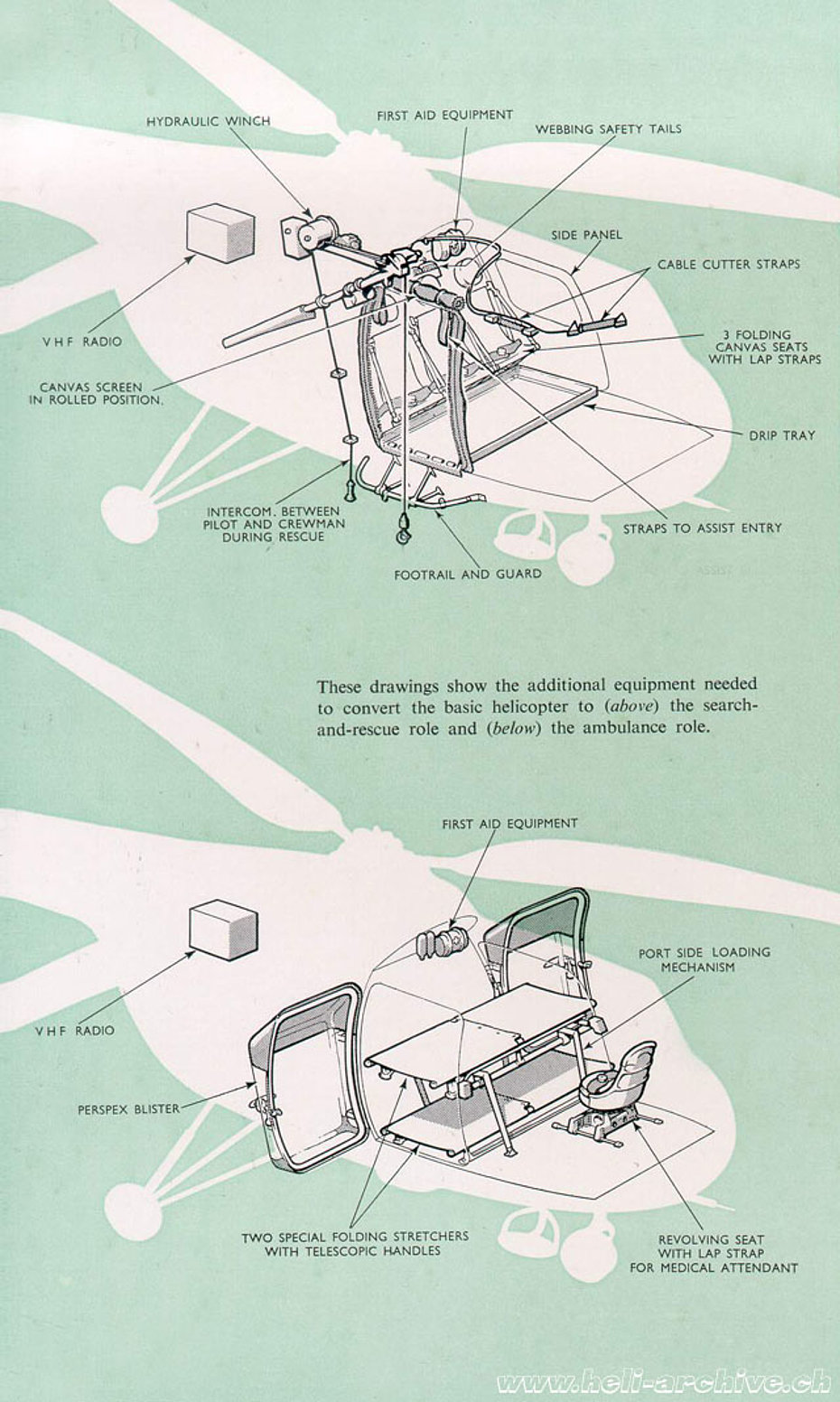

It differed from its predecessors in having a higher landing gear, more spacious luggage compartment and an increased maximum takeoff weight. The pilot position of this version was moved to the right. For search and rescue duties it could be equipped with a winch actuated by an hydraulic pump connected to the main transmission and bulked rear doors which allowed the transportation of two stretchers.

Altogether Bristol built 178 aircraft, of which 95 were manufactured in Filton and 83 in the factory of Old Mixon located in Weston-super-Mare. The last manufactured aircraft left the assembly line on December 5, 1958.

Military employment

Although this helicopter was built to meet both military and civil needs it was mainly used in the ranks of the army.

The first to receive the new helicopter was the Royal Air Force (April 1953). Among military users were the Royal Australian Navy and Air Force, the Belgian Air Force and the Bundeswehr (Luftwaffe and Marine). The latter ordered 50 aircraft which were designated Bristol Type 171 Sycamore Mk. 52. The first deliveries to the Federal Republic of Germany took place on May 31, 1957.

According to information gathered these deliveries occasionally created some resentment among certain workers that only a few years before were employed in the same factory for the construction of airplanes destined to defeat the Third Reich. The presence of the German uniforms was not greeted with particular enthusiasm by some subjects of Her Majesty the Queen.

Only ten years had passed since the end of WW2, but the global stability had again changed in the meantime.

Most part of the Bristol 171 (officially designated “Sycamore” by the Army and the Navy), was used for reconnaissance, light transport, flight training, observation, search and rescue on land and at sea duties.

Extensive modifications were carried out to enable the helicopter to accommodate two stretchers, which were carried one above the other athwart the machine. To house the stretchers two large “Perspex” blisters were incorporated one on each side of the fuselage. These special doors were detachable and could be replaced by ordinary faired doors when the aircraft was flying in a normal configuration.

In the ambulance role the passenger’s seat beside the pilot was installed facing aft for the medical attendant (if required a swivel seat could be provided).

The helicopter was used everywhere in the world, from northern Canada to Tasmania, from the Alps to the Southeast Asia's forests.

In the 1950s and early 1960s several Sycamore were employed for military operations in the former British colonies such as Malaysia, Borneo, Brunei, but also in Congo, on the island of Cyprus and during the crisis of the Suez Canal (1953) or the Aden Emergency (1963).

Environmental effects on the blades

Unfortunately in Malaysia a very serious problem surfaced.

Under the extreme hot and humid climatic conditions the wooden blades deteriorated due to moisture absorption, which caused swelling and consequent decay of the (already not very brilliant) helicopter’s performance.

Dynamic imbalance of the main rotor was another common problem which seriously affected the first generation of helicopter rotor blades like those of the Bristol 171.

However the most serious problem was another: with the humidity the glue joints started to fail and this led to the deposit of moisture in the internal structure of the blades and consequently dry rot.

On February 21, 1959 near Kuala Lumpur the aircraft registered XE 319 crashed from an altitude of about 100 meters after one of its blades disintegrated. The two occupants were killed in the accident.

Following this accident the Sycamore fleet was grounded. The problem was only partially overcome when blade-spar and external glued joints were sealed as suggested by the technicians to prevent the internal deposit of moisture. Initially heavy mass-balance weights were added to the blade tips to correctly reposition the centre of gravity. This improved the dynamic balancing and reduced vibrations. Finally the aircraft resumed normal duties in February 1960.

Unfortunately however the same kind of incident occurred on March 31, 1960 when one of the three Bristol 171 Sycamore Mk. 14 (registration OT-ZKC) purchased by the Belgian Government to serve with the Belgian military forces in Congo crashed near the airport of Kamina killing the three men onboard.

Again a similar accident took place on March 25, 1964 at the airport of Ternhill, Shropshire involving XL820. Both occupants lost their life.

Apparently this serious problem was never solved, perhaps because in the meantime, as we have seen, series production had already ceased and many Sycamores were already out of service.

Many in fact were damaged or lost during their service with the army. As for those employed on behalf of the British armed forces in the period between 1954 and 1966 around 70 accidents occurred. About half of these were attributed to pilot mistakes with some ten to failures or malfunctioning of the engine. Other incidents were caused by tail rotor damage.

Because of the long tailboom autorotation exercises required extreme caution. The Sycamore was not particularly suited for mountain operations due to its limited power reserve. It was also prone to ground resonance problems and as training helicopter it was penalized for the fact that it had only one collective pitch control lever.

While in Bundeswehr service some 13 accidents occurred with at least 3 attributed to engine malfunction.

All things considered it could be said that the Bristol 171 Sycamore for its design features, its mediocre performance and the reduced number of aircraft produced was not a great commercial success.

In addition, unlike other helicopters, its operational career was rather limited, lasting an average of 12-15 years only (the majority involving armed forces between the late 1960s and the early 1970s). By comparison it is interesting to note that some of its successors like the Bell UH-1D or SA 341 Gazelle are still operational after more than forty years of honorable service.

Civil employment

Among early civil operators, actually a few only, there were British European Airways (BEA), Autair, Australian National Airways/Ansett-ANA, Jayrow Helicopters which began its activities in 1965 and J. Rose Motors Ltd. also based in Australia. In Africa a Sycamore was used by Williamson Diamonds Ltd. located in Nairobi/Kenya.

Bristol 171 specifically manufactured for the civilian market were used for passenger and freight transportation, search and rescue flights, supply, observation and photo surveys and in some rare cases in agriculture for aerial spraying.

Apparently one of the reasons that limited its sales success was its high purchase price. Moreover considering its technical characteristics it is very probable that even operating costs were quite expensive.

At the end of their military service several Sycamores were donated to museums while others were used by civilian operators.

Since 1970/1971 Sycamores were employed in Germany by Feuerwehr-Flugdienst Niedersachsen (fire department Lower Saxony), North-Helikopter based in Edemissen (near Brunswick), Hubschrauber-Flugdienst based in Mellinghausen (near Bremen) and Luftrettungsdienst (air rescue service) based in Dusseldorf which used several aircraft. The last Sycamores employed for civil activities ended their activities in Germany in June 1988.

Technical description

The following description concerns the Bristol 171 Mk. 4 which is a five-seater helicopter of standard configuration of the so-called first generation. Its general look is very similar to other designs of the late 1940s such as the American Sikorsky S-51 and the Soviet Mil Mi-1 Hare.

The fuselage, entirely built in metal, is composed of four sections: the front one with the cabin, the center one that accommodates the engine and the transmission, the intermediate section and the tail boom. Cabin, intermediate section and tail boom are built with a monocoque structure. The center section is made of welded steel-tubes. Detachable metal panel cowlings protect the engine.

Cabin

Access to the cabin is enabled through four doors. The two front doors are hinged and open forward as in cars while the rear doors open backward. The pilot sits on the right and has conventional controls. Despite the large size of the main rotor, which has a diameter of 14.8 meters, the helicopter is not equipped with hydraulic controls, so the piloting required muscular arms.

To ease the efforts of the pilot, on the center console there are two wheels between the two seats that act as mechanical trim. The pilot could use them to correct the attitude of the helicopter, therefore the force required was lower and this made the piloting less strenuous.

Next to the pilot's seat there is the co-pilot (or front passenger) seat and behind there are three folding passenger seats.

Due to the considerable height of the floor from the ground, to facilitate entry of the occupants in the cabin, the helicopter is provided with a foot rest. Pilot and passengers have a good visual in all directions.

CG compensation system

Even if none of the publication consulted mention it, early Bristol 171 must have been somehow very sensible to weight and thus CG variations. This would explain the introduction of a mechanism used to keep the center of gravity (CG) within the limits.

The CG compensating system was introduced for the first time on Mk. 3 series which had a shorter cabin than its predecessors in order to improve the pilot’s visual. According to the publication "Pilot's notes - Sycamore HR Mk. 14" published in February 1958 it was quite easy to exceed the longitudinal CG limits, so the pilot had to pay great attention to calculate with care weight and disposition of the load transported. The mechanism incorporates two tanks. The first with a capacity of 25 litres mounted under the floor of the cockpit (left side) and the second with 26 litres capacity mounted in the pylon supporting the tail rotor. The two tanks are interconnected by means of two electrical pumps mounted in parallel. The transfer of all the fluid (water mixed with antifreezing) from one tank to the other required about 3.5 minutes and shifted the CG by 4.7 inches (12 cm). Since the two fuel tanks are located behind the CG, in flight the CG moved forward as fuel was used, and for every 5 Imp gallons (23 litres) of fuel used, 3 lbs (1,5 kg) of CG compensator fluid should be moved aft in order to keep the CG position constant. In the hover or cruising flight the compensator should be adjusted to maintain a cyclic stick position between 0° and 2° forward respectively.

For each passenger seated in the cabin it was necessary to pump 1,5 gallon (7 kg) of fluid to the rear tank.

Engine

In the center section of the fuselage, inside a cubic structure constructed with welded steel tubes, there is the engine with its accessories (like for example the oil tank and the oil pump). Detachable metal panels protect the engine.

The Bristol 171 Mk. 4 is powered by a 9-cylinder radial aircooled 718.6 cu.in. (11.78 litres) Alvis Leonides LE 23 HMV (civil 524/1, military Mk. 17302) engine.

This engine weighing 331 kg is installed horizontally. Maximum take-off power at sea level is 386/401 kW (525/545 hp) at 3,200 rpm (46.0 in Hg) limited to 5 min.

In cruise flight rpm are reduced to 2,800 with a an admission pressure of 34' inHg. With these parameters the engine developed about 345/254 hp/kW.

The average hourly consumption in cruise flight was about 120 litres.

The crankshaft carries a single-plate centrifugal clutch and the engagement of the two shafts (the motor gearbox shaft and the rotor mast) starts at approximately 950 rpm and is completed at about 1’200 rpm. The clutch casing provides a hub for the cooling fan blades.

Cooling air enters the engine compartment through a grille immediately in front of the main rotor hub and helps to cool the rotor gearbox before passing through the engine compartment and leaving the fuselage though the outlet below the engine compartment.

Engine driven cooling fans draws air through the intake above the cabin. Air is ducted from the fan past the fully-cowled and baffled engine and exhausted through a grille at the bottom of the fuselage centre-section. Steel cowlings above the cylinders and steel bulkheads below enclose the engine into a fireproof box.

The entire power unit is isolated in a fireproof casing, and the fire extinguisher equipment is provided in accordance with standard requirements.

Fire in the engine bay is detected by 11 non-resetting flame-switches, 6 around the engine and 5 around the accessories gearbox. Operation of any flame-switch illuminated a warning light in a fire-extinguisher push-button on the instrument panel. The light which could be tested by pressing an adjacent switch remained on after the fire was extinguished.

In case of fire emergency in the engine bay the pilot pushed a button on the control panel that operated a Graviner spray-ring fire-extinguisher that sprayed methyl bromide (a highly toxic substance banned in the ‘60s) around the engine.

The engine exhaust is located on the right hand side. However initially this sometimes created problems, especially when the helicopter was equipped with a winch for SAR operations. The person hoisted on board was in fact at times exposed to the hot exhaust gases which could also enter the cabin, dangerously raising the level of carbon monoxide. To overcome these problems the exhaust pipe was modified to divert the gas flow backwards.

The helicopter is provided with two flexible fuel tanks aft of the engine. The fuel tanks (the engine uses 100/130 octane fuel) were filled separately. The main tank with a capacity of 295 liters (65 Imp gallons) is mounted above the 109 liters auxiliary fuel tank. The fuel is transferred from the auxiliary tank into the main tank by means of an electric pump.

A 29V 1’500W DC generator supplies power for the electrical services and charges a 24V 25Ah battery mounted under the cabin floor, aft of the observer’s seat. The main gearbox driven generator is combined with a vacuum pump providing instrument suction and generator cooling.

The socket for the external power supply is located on the right side in the intermediate section.

The luggage compartment has a volume of 0.56 m3; it’s access door is located on RH side. Based on CG specifications up to 90 kg of baggage can be loaded. The radio equipment was also originally installed in the intermediate section.

The helicopter can also be used as an aerial crane and depending on the cargo hook installed (model 800 or 806) it could carry up to 227 kg (models 800 and 806) or up to 454 kg with cargo hook model 952.

The Mk. 4 has a longer-stroke tricycle landing gear, with fully-castoring self-centering nosewheel, and hydraulically-operated brake units on the main wheels only. The brakes are operated by a lever on the starboard side of the console.

Tail boom

The long metal monocoque tail boom holds the three-blade tail rotor whose blades are also made of wood except for a steel rod on the leading-edge of the spar to increase strength.

A tail boom bumper protects the tail rotor from undesired contact with the ground. In fact considering the length and the particular form of the tail boom, which is slightly inclined downwards, the pilot had to be very careful when maneuvering at low altitude.

The helicopter is fitted with a small horizontal stabilizer mounted on the structure of the tail rotor gearbox.

Rotor system

As previously described, the Bristol 171 is equipped with a three-bladed fully articulated main rotor and three blades tail rotor.

The blades, of trapezoidal shape are of Bristol design, wooden construction with Hydulignum spar along the leading edge, spruce and ply ribs and plywood covering. Two sheet metal tabs, one in the vicinity of the blade tip and the other near the root, correct aerodynamic balance. There is also of the trim tab for the alignment of the blades (tracking).

The main portion of the blade is attached to the metal root by a series of plates interleaved with spar laminations at one end and a pick-up with two bolts in the metal root portion at the other end. By removing one bolt from each blade it can be folded back and secured to save hangar space.

Wooden rotor blades were a common feature distinguishing helicopters of the so called first generation.

Contrary to metal or composite blades, which are more solid and have a longer service life, wooden blades were not usually interchangeable, whereby damage to one blade invariably replacement of the other blades. This evidently meant a lot of money for the operator!

The helicopter was equipped with a rotor brake mounted behind the main transmission. Depending on the model it could be mechanical or hydraulic.

Performance

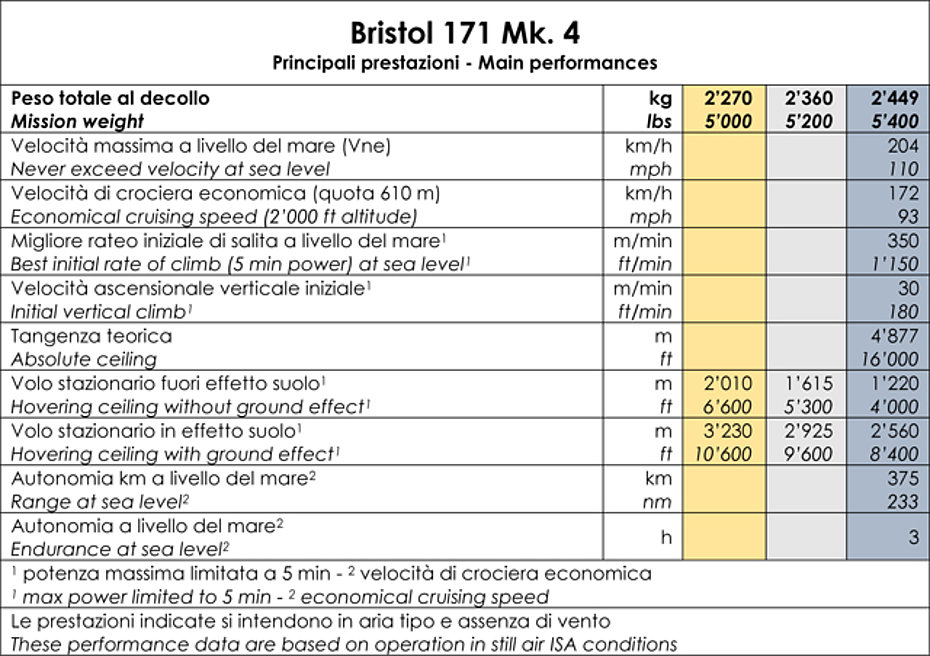

Below is a table with the performance data of the helicopter:

Engine and rotor limitations

At sea level the maximum take-off power (limited to 5 minutes) was obtained at 3’200 rpm and 44 inHg (inches of mercury) PSI (Pounds per Square Inch - PSI). The economic cruise speed was obtained with 2’800 rpm and 34 inHg PSI.

In flight the maximum permissible rotor speed was 287 rpm, while the minimum rotor speed was 245 rpm.

Autorotation

In the event of an engine or tail rotor failure during the cruise flight (at an altitude higher than 120 meters above ground) it was necessary to execute an autorotation by reducing the collective pitch to the minimum and simultaneously stop the engine. During the autorotative flight it was necessary to maintain a constant speed of approximately 50 knots (92.5 km/h).

The maximum glide distance in autorotation was obtained with a speed of approximately 70 knots and 245 rpm.

Optional equipment

The list of additional accessories available for the Bristol 171 Mk. 4 included: hydraulically-powered hoist for search and rescue operations, single point suspension system hook for external loads, two litters and medical attendant seat in the cabin for aerial ambulance operations, bulged doors, spray or dusting kit.

The Bristol 171 in Switzerland

During the summer of 1953 Mr. E. Asper, the Swiss representative of the Bristol Aeroplane Company, informed the technical service of the Swiss Army that the British manufacturer desired to present its new helicopter in Switzerland.

At that time the company was promoting its sales. For this reason one of its aircraft was specifically designated for this purpose. The helicopter concerned was the Bristol 171 Mk. 4 registered G-AMWI on December 1, 1952. The invitation was extended to all potential customers.

The newly-founded Schweizerische Helikopter AG (SHAG - Heliswiss) was of course invited to attend the flight test program planned for the month of September.

The latter helicopter operator (to note that at that time there were only two civil helicopter companies in Switzerland, SAHG and Air Import) conducted a series of evaluations in order to identify the most suitable helicopter to its needs.

Bristol embraced with enthusiasm the idea to test its new helicopter in the Swiss Alps, a destination very popular and appreciated by the British who are known for their passion for mountaineering. In 1865 the Englishman Edward Whymper had been the first to make a successful ascent of the Matterhorn (4'478 meters – 14'692 ft), the most famous mountain of the Swiss Alps.

G-AMWI left the Filton factory, arriving in Switzerland on September 19, piloted by Peter Wilson who was accompanied by Mr. Lewis RAM as observer and A. Luscombe as flight engineer.

The next day the English pilot carried out a reconnaissance flight on board of a Piper Cub piloted by Raymond Gerber. The latter gave his passenger a series of practical indications, especially concerning the flying techniques in the Alps.

Gerber was the first helicopter pilot employed by Schweizerische Helikopter AG. It should also be recalled that in February of that year Gerber spent a short period in England to attend a helicopter pilot course, and while there he also had the opportunity to fly along with Captain Jock Cameron with one of the Bristol 171 Mk. 3 in service with the Experimental Helicopter Unit of British European Airways (BEA).

Unfortunately the Swiss pilot died a few weeks later in a helicopter accident when his helicopter hit a power line in the vicinity of the airport of Belp/Berne.

Tests with the Bristol 171 began on September 21 when Wilson made the first landings in Zimmerwald, a village located in the hills south-east of Belp at an altitude of about 850 meters (2’800 feet). That same day the helicopter carried out a series of passenger flights in the Bütschelegg region (1’050 meters/3’550 ft).

Mountain air rescues

The second day of demonstration was certainly the most challenging for the English crew. The helicopter was in fact used in the Gantrisch region situated in the Pre-Alps of the Canton Berne at an altitude of approximately 1’650 meters/5’400 feet. The program included handling demonstrations, transportation of underslung loads of about 150 lb, stretcher loading and unloading, removal of the Perspex blisters, passenger flights. The helicopter was also employed for some air rescue exercises using the winch.

Apparently according to Wilson’s report the helicopter landed several times without difficulty at its maximun take-off weight of 2’449 kg (5’400 lbs).

The Bristol 171 was then tested on the lake of Thun where it was used for some rescue exercises carried out with the assistance of the Swiss Life Saving Society.

The last evaluation flights were planned on the Sanetsch Pass (2'250 meters) region where a new power line was under construction.

Wilson wanted to show the helicopter’s ability carrying supplies and building equipment directly to the construction site from a nearby base. Unfortunately a sudden snowfall forced the helicopter on the ground during the morning. When the weather eventually cleared, it was too late to complete the program, but Wilson decided to land at least one time on the Sanetsch Pass showing the helicopter capabilities to operate at high altitude.

The tests enabled to establish that the helicopter could carry a payload of about 250-300 kg up to an altitude of about 2'100 meters (6’900 ft).

The test flights were observed with great interest by members of the Schweizerische Helikopter AG, representatives of the Army, and personalities in the Swiss aviation world.

However, contrary to Bristol’s expectations the enthusiastic report written by Wilson didn’t infected any Swiss potential customer.

The helicopter G-AMWI continued to be used as a demonstrator during the following years. In 1961 it was converted into Mk. HR.51 version for the Royal Australian Navy and sent to Australia. There it was used for about a decade before being definitively withdrawn from service.

Today it is exhibited at the Museum of Aviation Camden, Narellan near Sidney.

The Bristol 171 comes back to Switzerland

In June 1988 Peter Schmid, a farmer and wine producer living in Berneck, Canton St Gallen, and a passionate private helicopter pilot, decided to purchase some Bristol 171 based in Germany. During the summer he did the transition course with the flight instructor Alfred Winderlich on the helicopter registered D-HALD. Schmid transferred this helicopter to the airport of Altenrhein/SG where he founded the "Sycamore Flyers Switzerland". This first helicopter was soon joined by another one registered D-HELM. Both were used for private flights. In August 1989 the first of the two Sycamores received the special Swiss registration HB-RXA while the other one was subsequently registered HB-RXB. During 1991/1992 the latter underwent major maintenance work and received a new livery in the colors of the last Sycamore used by Squadron 32 of the Royal Air Force for VIP transports. Unfortunately on August 19, 1992 at Widnau/SG the HB-RXA began to vibrate so strongly after landing in a meadow that the pilot lost control. Shortly afterwards the main rotor blades hit the ground and the helicopter toppled over on its right side causing significant damage. Fortunately in the accident, due to the ground resonance phenomenon, no occupant was injured. For about twenty years the HB-RXB remained in the Swiss register.

In August 1989 D-HELM received the Swiss registration HB-RXA while the second was much later registered HB-RXB. During 1991/1992 HB-RXB underwent a complete overhaul and received a new RAF VIP livery like XG544, the last Sycamore flying with Squadron no. 32 of the Royal Air Force.

Unfortunately, on August 19, 1992 in Widnau/SG shortly after landing in a meadow HB-RXA began to shake so hard that the pilot lost control and the main rotor blades hit the ground. The helicopter rolled over on its right side and was seriously damaged. Fortunately during this the accident attributed to a ground resonance, nobody was injured.

HB-RXB remained in the Swiss aircraft register for about twenty years.

In June 2010 it was sold along with all spare parts to the “The Flying Bulls” (a company of Red Bull) based in Salzburg (Austria). Following an overhaul this Bristol 171 is flying again to the delight of all the “old timers” enthusiasts. Meanwhile it has received the new Austrian registration OE-XSY.

Did you know that…

The helicopter as we have seen received the military designation Sycamore. Someone in fact, perhaps mindful of the childhood games, compared the (rotor of) the helicopter to the seeds of the Sycamore maple (Acer pseudoplatanus) tree whose seeds rotate when falling. This helps them to spread further from the parent tree.

Raoul Hafner worked as technical director for Westland Aircraft until 1970. After his retirement he continued to work on helicopters cultivating another great passion, the one for sailing boats which unfortunately cost him his life. On November 14, 1980 Hafner was fatally injured in a yachting accident in the Bristol Channel.

Westland developed a helicopter derived from the WS-51 1A known as Westland Widgeon which had performance and characteristics very similar to those of the Bristol Sycamore. The prototype G-ALIK made its first flight on August 23, 1955. This helicopter had limited success: only 15 were manufactured between 1955 and 1959.

Videos

This rare document shows the Hafner R. II Revoplane during a test flight: https://www.youtube.com/watch?v=FIt1XnZJZK

Interesting links

Have a look to this interesting link: "Bristol 171 Sycamores in Australia - A listing compiled by Geoff Goodall": http://www.goodall.com.au/australian-aviation/sycamore/bristol-sycamore.htm

Special thanks

A special thank goes to Dieter Hasebrink, Michael Mau, Ken Elliott and Geoff Goodall who provided historical and technical documentation used to prepare this article.

HAB 12/2015