Like the alchemist, Sikorsky in 1970 gave the S-58 the elixir of long life - the Pratt & Whitney Canada PT6T-3 Twin Pac transformed it into the S-58T making it one of the longest-lived operational helicopters.

Origins and development

As previously written in the article devoted to the Sikorsky S-58, on January 30, 1957, Sikorsky made fly a prototype known as the HSS-1F equipped with two General Electric T58 turbines instead of the original Wright R-1820 radial engine. Tested by the U.S. Navy as a flying test bed, the twin-engine "Seabat" was not as successful as hoped.

Several years elapsed before the U.S. manufacturer decided to re-engine its workhorse with a more modern, high-performance powerplant.

Underlying this decision was Sikorsky Aircraft's willingness to accommodate requests from various civilian operators to explore the possibility of equipping their S-58s with turbine engines to improve its performance and give it a new lease in life. Sikorsky Aircraft which stopped the production in series of the S-58 in 1969 (the last one left the assembly line in January that year), launched a series of test and studies that showed that the idea was both economically and operationally interesting.

After a technical evaluation of the engines available that met the power, configuration and reliability requirements, the Pratt & Whitney Canada PT6T-3 Twin Pac turboshaft engine was selected. The Twin Pac turboshaft engine was unique providing more than sufficient power required with the additional feature of twin engine reliability.

At the annual meeting of the Helicopter Association of America held in Las Vegas between January 11 and 14, 1970, Sikorsky Aircraft president Wesley A. Kuhrt, publicly announced its intention to produce and market a retrofit kit (initial estimated cost 250,000 USD).

The decision was obviously greeted with lively enthusiasm: thus the Sikorsky S-58T was born.

For studying the installation of the new power unit, an S-58 previously in service with Carson Helicopters of Perkasie, Pennsylvania, was stripped of the radial engine and its accessories and readied to be modified according to the blueprints and a mock-up of the S-58T previously prepared by Sikorsky technicians.

By January 1970 an engineering design group, averaging ten people, was given full autonomy to design, build, test, develop, and certify the S-58T.

Existing engine mounting points were used to hold a cantiveler platform for the Twin-Pac in the S-58T’s elongated nose. To connect the PT6T-3 to the main transmission a new 154 kg (341 lbs) angle change gearbox was designed. This component, which adapts the engine drive shaft to the existing S-58 main drive shaft, replaced the original hydraulic clutch and cooling fan of the R-1820 engine – the latter absorbed about 55 shp on the S-58 – had an initial 1,000 hours overhaul period (the TBO of this component was later augmented to 2’500 hours).

Since the weight difference between the radial engine and the new PT6T-3 caused a change in the CG (in total to convert an S-58 into a S-58T involved replacing 2,456 pounds with 2,020 pounds, resulting in a weight saving of 198 kg ore 436 pounds), the nose was extended by about 65 cm (26 in.) to balance the loss of weight. New clamshell doors made of fiberglass were designed above which stood out the two large air intakes that together with the engine exhaust made the S-58T version immediately distinguishable.

The two engine sections were separated and enclosed by firewalls. The fuel system was changed to feed both engines.

The engine installation requirements of structural mounting, controls, fuel, lubrication, instrumentation, accessories, fire protection, inlet and exhaust systems were designed and manufactured as a conversion kit to be installed at Sikorsky or at customer’s facilities.

To monitor the functioning of the new powerplant and accessories, the instrument panel was redesigned. Modifications in the cockpit included a new collective pitch control. The engine controls incorporate twist grips for engine starting and emergency manual fuel control operation. A beeper control on the collective is used for power turbine speed control. The engine control is designed to permit normal operation by a single pilot.

The other main components having a TBO ranging between 1,000 and 2,500 hours retained their potential.

As program director Robert F. Daniell stated, engineers during the conversion retained the standard S-58 where possible.

Beginning in May 1970 and throughout the summer, the small team made the necessary modifications.

The first test flight of the prototype registered N8478 was made on August 26, 1970.

By January 1971, while awaiting FAA certification, the first S-58s were converted to be delivered to customers.

Unfortunately on January 22, 1971 the prototype of the Sikorsky S-58T was damaged during an attempted autorotational landing near Richmond (VA). The aircraft was enroute from Stratford to Los Angeles where it was to be demonstrated at the Helicopter Assn. of America convention. Investigation indicated the aircraft lost power after its fuel was exhausted. None of the five-man crew was injured.

After an extensive series of tests conducted at the Stratford plant, Sikorsky Aircraft was granted a supplemental type certificate (SH71EA) on April 15, 1971, to install the Pratt & Whitney Aircraft PT6T-3 engine in the S-58B and S-58E.

According to information gathered, Sikorsky spent about 4 millions dollars developing the helicopter, which was almost identical to the standard S-58 from the clutch onwards.

A few weeks earlier Sikorsky Aircraft reported that the fleet of S-58/H-34s had accumulated about 7 million flight hours.

First deliveries

Even before obtaining FAA certification Sikorsky Aircraft began a series of demonstration promotional tours, the first of which took place in March/April 1971. The prototype registered N8478 in the "executive" version was presented in various American cities, among them Pittsburgh, Chicago, Denver, New Orleans, Dallas, Houston, St. Louis, Detroit and New York.

In a release issued by the manufacturer on April 19, 1971, stated that the first mass-produced conversion kit was shipped to Udorn/Thailand airport for installation by Air America mechanics.

The first S-58Ts left the assembly line (although it would be more correct to speak of conversion line) for delivery to operators in June 1971.

That month, 8 S-58Ts had already been completed, 16 were awaiting conversion while another 16 kits were about to be provided to those operators eager to convert their S-58s.s

Owners who wished to do so could send their S-58s to the manufacturer.

For the conversion, Sikorsky employed about seventy people who were able to prepare two aircraft per month.

The company was able to custom tailor an S-58T to the operator’s need, giving him the exact interior configuration, avionics or the features he desired.

Contrary to what was anticipated, the cost of a “new” S-58T rose to $485,000, thus slightly more than originally planned (425,000 USD), while the cost of the upgrade kit alone was 285,000 USD.

The mothballing of many armed forces H-34s made available a large quantity of airframes and spare parts lying in military warehouses in addition, of course, to those of the manufacturer.

According to Sikorsky Aircraft approximately 40 S-58s and conversion kits were forecasted to be delivered in 1971.

For this reason 30 H-34s were purchased from the French armed forces and 21 from the Israeli armed forces for conversion. These were joined in 1973/1974 by 24 H-34s mostly from the ranks of the army of the Federal Republic of Germany. As stated in documents of the time, the Bundeswehr considered converting its H-34s, but after an evaluation they preferred to purchase the new Bell UH-1Ds and Sikorsky CH-53Gs.

The aircraft from Europe, after being loaded aboard cargo ships, were shipped to Newark, New Jersey, and from there conveyed to the manufacturer. Some of the German aircraft were converted at Sikorsky Aircraft, while others were offered for sale to be converted.

Beginning in the early 1970s, the Sikorsky S-58T thus returned to live a second youth.

Among the first customers to purchase the S-58T were Okanagan Helicopters, which in June accomplished near Vancouver what was called the first serious attempt at logging by helicopter in Canada. The S-58T picked logs weighting up to 2’268 kg (5,000 pounds), flew then down a steep mountainside and then dropped them into the water. The logs were then conveyed to Vancouver.

Another major operator was the aforementioned Air America.

On January 15, 1973, during the annual meeting of the Helicopter Association of America (HAA), the American manufacturer announced that 40 kits and aircraft had been supplied. Sales were broken down as follows: 15 aircraft delivered complete from Sikorsky Aircraft, 8 built from Sikorsky-supplied fuselages with the turbine retrofit kits installed by the customers and 17 with the kits installed by the customers in their own S-58s.

The list of S-58T operators included: Airfast Helicopter Utilities (2), Ontario Hydro (2), Okanagan Helicopters (7), Heliswiss (1), Chevron Oil (1), Cordon International (5), Quasar (1), Thai Agricolture (1), Greenlandair (1), Carson Helicopters (3), Helicol (1), Air America (7), United Aircraft Corp. (1) and Jelco (1).

In January 1975 at HAA's 27th Annual Meeting held in Anaheim, Sikorsky Aircraft announced that it would produce a new upgraded version of the S-58T initially called the "Super T" starting later that year. Better known later as the S-58T Mark II, it was equipped with the more powerful Pratt & Whitney PT6T-6 a main rotor-mounted vibration damper (known as bifilar main rotor vibration absorber it improved pilot and passenger comfort and reduced aircraft maintenance), a reinforced tail rotor pylon, and optionally a protective stainless steel protection strip on the leading edge of the main rotor blades. The strip provides a sacrificial wear surface which is repairable during the service life of the blade, and is expected to produce the following three results:

- extend the time between repairs required due to leading edge abrasive wear;

- maintain consistant performance of the blades because of little, if any, changes in airfoil characteristics due to erosion or abrasion;

- increase potential rotor blade life;

With these modifications, the helicopter's overall performance (including one engine inoperative capabilities) and occupants comfort were further improved. As an example compared to the Dash three version, the PT6T-6 Dash Six could deliver its full power up to an altitude of 2,165 meters (7,100 feet) instead of 1,220 meters (4,000 feet).

By July 1975 the base selling price of the converted aircraft fitted with standard equipment had meanwhile risen to 685,500 USD, while that of the kit was offered at 404,500 USD.

In the same year the cost of a Bell 205A-1 was 525,000 USD. A comparable, though slightly smaller brand new Bell 212 powered by the same Pratt & Whitney PT6-T cost 695,000 USD.

Compared to these models the S-58T, at least on paper, could carry the same weight at higher altitudes as well as offering more cabin space.

During the 1970s and 1980s Orlando/Florida-based Orlando Helicopter Airways Inc. converted 17 aircraft to S-58Ts. This company also designed a new configuration known as OHA S-58T Viking.

At least 18 conversions were made by Chicago Helicopter Airways, 12 by Carson Helicopters Inc. and 3 by Imperial Airways Inc.

The agreement between Sikorsky Aircraft Division and California Helicopters

In 1981 California Helicopters located in the Los Angeles suburb of Sun Valley purchased the support program for the S-58/S-58T from Sikorsky Aircraft Division of United Technologies Corporation. California Helicopters was founded in 1958 to provide support for the commercial helicopter industry. From 1970 it specialized in the Sikorsky S-58 and S-58T series.

The deal included the rights to build the S-58T conversion kits, the manufacturer’s tooling, blueprints, technical documentation and an estimated 25 million USD in spare parts.

Along with these items came the responsibility of supporting the worldwide feet of S-58s and S-58s and H-34s. At that time the American company had the largest inventory of certified commercial parts in the world for the S-58/S-58 T helicopters. In addition it had the FAA Parts Manufacturer Approval to manufacture all of the parts for the S-58/S-58T except the rotor blades and engines. Through its wholly-owned subsidiary California Helicopter Airways Inc. a licensed FAA repair station, CH provided overhaul services for dynamic components completed to O.E.M. standards and in full compliance with Sikorsky overhaul procedures.

As part of its ongoing activities CH refurbished S-58T airframes to an overhauled condition, either on contract basis with operators or for resale.

According to an article published in the July-August 1986 edition of the Vertiflite magazine at that time California Helicopter International supported a worldwide fleet of 110 S-58Ts and was the only authorized manufacturer of these aircraft and its spare parts.

Five years later, in January 1991 Interavia magazine stated that there were about 80 S-58Ts in service.

Nowadays the type certificate for the S-58 series is in the hands of Centerpointe Aerospace, Inc. based in Royse City, Texas. Founded in 2004, this company is an FAA 145 repair station, possessing the ability to perform comprehensive maintenance on all Sikorsky and MD civil helicopter models. Its services range from scheduled (and unscheduled) maintenance to depot level repair and overhaul to logistics and engineering services. Centerpointe Aerospace specializes in legacy aircraft, proudly holding the Type Certificates for the Sikorsky S-55, S-58 and S-62 models. The company provides broad support functions throughout the world in both domestic and international markets. By embracing the core values of its parent company Aviation Resources Holding LLC, it strive to embody their motto of “Effective and Efficient” support services.

Centerpointe Aerospace is currently working several initiatives designed to breathe extended life into the S-58T. Expected soon is the “S-58T3B” STC allowing installation of the PT6T-3B engine. Once finalized this STC will allow the S-58T operators to incorporate the PT6-3B engines, take full advantage of current in-production engines, and allow participation in P&WC power by the hour (ESP) program.

Additionally, new replacement metal rotor blades will be available followed closely by composite blades, projecting a 21% increase in lift.

Nowadays, the S-58T is still used for commercial operations, but it is difficult to exactly establish how many are operational. Among the US operators there are for example:

- 5 State Helicopters based in Royse City, Texas;

- Midwest Helicopter Airways in Willowbrook, Illinois;

- Aris Helicopters based in Riverside, California, which advertises on its website, among other things, that it has an extensive inventory of spare parts for the S-58T and other Sikorsky models;

- Aircrane Inc. based in Winder, Georgia;

These operators use them to accomplish aerial operations of all kinds. They are often employed to lift heavy air conditioners onto the roofs of buildings.

It is also difficult to establish with precision how many S-58s have been converted over the years. An article in July 1975 stated that more than 100 conversions had been made up to that time.

More than one source indicates that there should be about 160 in total. Of these about 120 for civilian use, the remainder for military forces. Major military operators included Royal Thai Air Force and Indonesian Air Force. Among the military operators there were: Argentina (2), Costa Rica (2), Haiti (2) e Nicaragua (?).

Conversion

At Sikorsky Aircraft's conversion line at Stratford (later the line was moved to Bridgeport), S-58s were stripped of every component. The airframe was partially disassembled, sanded and inspected for any areas of corrosion, lose or missing rivets, dents, cracks or wrinkled skin. Where necessary it was repaired before the installation of the new engine started. On average the installation of the Twin Pac required:

- 800 hours for sheet metal and structural work

- 550 hours for the electrical system

- 100 hours for plumbing

- 250 hours for fabrication and installation of components

- 300 hours for checks out and test

The transformation thus required approximately 2,000 hours of work, while preparing a complete S-58T required 4,750 hours. Sikorsky Aircraft was able to customize an S-58T according to the operator's needs.

The Pratt Whitney PT6T-3 Twin Pac

United Aircraft Canada developed this power unit during 1959-1964. As of January 1, 1970, it was reported that 3,411 had been built that had accumulated a total of 3,429,276 operating hours.

The Pratt & Whitney T-400 Twin Pac (this is the original US military designation), commercially known as PT6T-3 includes two power units, each consisting of T-74 (PT6) turboshaft engines and a combining gearbox having a single common output shaft.

Although capable of producing 1,323/1,800 kW/shp (the radial Wright R-1820-84 produces 1,137/1,525 kW/shp), the engines are limited to 1,107/1,505 kW/shp (1,195/1,625 kW/shp for the PT6T-6) through a torque limiter installed on the combining gearbox. The system is thus never operated above the torques approved for the S-58T drive system. Maximum continuous power is limited at 1’195/1’262 kW/shp.

The engine aerodynamic components are identical to the PT-6 engines except that the gas generator turbine nozzle vanes are cooled, thus permitting the high temperature required for the increased power level without effect on life. The combining gearbox reduces the full speed output of the PT-6 gas generators to a single output speed through a pair of overrunning clutches and a 5:1 reduction ratio. The gearbox also contains a torquemeter for each engine and an independent oil system for maximum safety during emergency single engine operation.

During normal operations with maximum continuous power, fuel consumption is about 435 litres/hour (115 USG).

To date, this power unit has been produced in 11 variants, and its versatility has been demonstrated in a wide range of applications around the world.

Commercial employment

Like its predecessor, the Sikorsky S-58T has been used almost everywhere in the world by helicopter operator for offshore services.

As an aerial crane and flying fire fighter the helicopter has also experienced some success. During the 1980s and 1990s New York Helicopter employed a fleet of S-58Ts to provide scheduled service connecting Manhattan with three major New York airports, Kennedy International (KJFK), LaGuardia (KLGA) and Newark International (KEWR), all three are served from the East 34th Street heliport on the East River. The company also provided sightseeing and private charter operations.

In the 1990s, the list of S-58Ts users included the Los Angeles County Sheriff's Department (N724SB, N392JK, N64CH), which previously employed some H-34s in the 1970s and early 1980s.

Technical Description

With the exception of the Pratt & Whitney PT6T-3 Twin Pac power plant and related instrumentation and power supply, the helicopter is almost identical to the S-58s. Fuel is carried in three multi-cell fuel tanks located in the forward fuselage section below the cabin floor. The forward tank consists of six interconnected cells, the center and aft of three interconnected cells. The forward tank provides fuel to the number one engine, and the center and aft tanks provide fuel to the number two engine. A cross feed capability system has been installed to provide a balancing of fuel between the two separate systems. Each tank has a filler unit on the right side of the fuselage.

Accessories

The Sikorsky S-58T could be equipped with various accessories. The list depending on the intended use initially included for example: rescue hoist, 2’268 kg (5,000 lbs) capacity cargo sling, 150 USG external auxiliary fuel tanks, floats (pop out emergency flotation gear or fixed also called "donut"), quilted blanket interior, 16 seats, 8 stretchers, additional instrumentation.

Added to this list later were: strengthened tail gear box housing, addition of 8 windows in cabin, pilot and co-pilot bubble windows, outside step for pilot and co-pilot above landing gear V support, addition of access door to number one engine fuel control, addition of pylon access steps, 16 airline-type passenger seats, side walls and improved cabin lighting, improved fuel boost pumps, removal of main gear box fairing and relocation of fairing, EAPS option, air conditioning.

According to a Sikorsky Aircraft newsletter dated January 15, 1973 conversion from the Wright R-1820 engine to the PT6T reduced the aircraft’s empty weight and increased altitude lifting capacity by 680 kg (1,500 lbs) or permitted the carrying of the same load 1,280 metres (4,200 ft) higher, and provided a drastically quieter helicopter.

The installation of the new PT6T allowed the transportable load to be increased by 313 kg (691 lbs), which was roughly the weight difference between the Wright R-1820 engine or 646 kg (1,424 lbs) and the P&W PT6T-3 (321 kg - 707 lbs).

On the practical side, however, this difference was tapered off when the Bifilar vibration absorber, the special vibration damper mounted on the rotor head, was fitted.

Although in sea-level cruise flight the turbines consume 22 gallons more, the extra 110 knots of cruise (as opposed to the 85 kts of the S-58) means that the range is nearly identical for the two models. Hoovering performance in ground effect on a hot day (ISA +20) increased from 790 metres (2,600 feet) to 2,350 (7,700 feet) in the S-58T.

The Sikorsky S-58T in Switzerland

Starting from 1963, with the purchase of the two new Agusta-Bell 204Bs (HB-XBN and HB-XBO), the lifting capacity of Heliswiss' helicopters was considerably increased from 200-250 kg (440-550 lbs), this was generally the useful load of the Bell 47G2s, to 1'000 kg (2,200 lbs). In 1967, thanks to a series of important structural modifications made on the helicopter registered HB-XBO (among them a new and more powerful Bristol Siddeley Gnôme H.1200 turbine and longer main rotor blades) the lifting capacity of the helicopter was increased from 1'000 to 1'500 kg (2,200 to 3,205 lbs).

Thanks to the memories left to us by Walter Tschumi (1931-2003), ex chief-pilot of Heliswiss, and author of the book "Blick zurück, mein Leben als Flieger im letzten Jahrhundert - Ed. Jordi, 2003 ISBN: 3-906562-35-2" (A look back, my life as aviator in the last century) we can reconstruct in detail the history of the HB-XDT, the first Sikorsky S-58T to be imported in Europe, and the first (and only) registered in Switzerland.

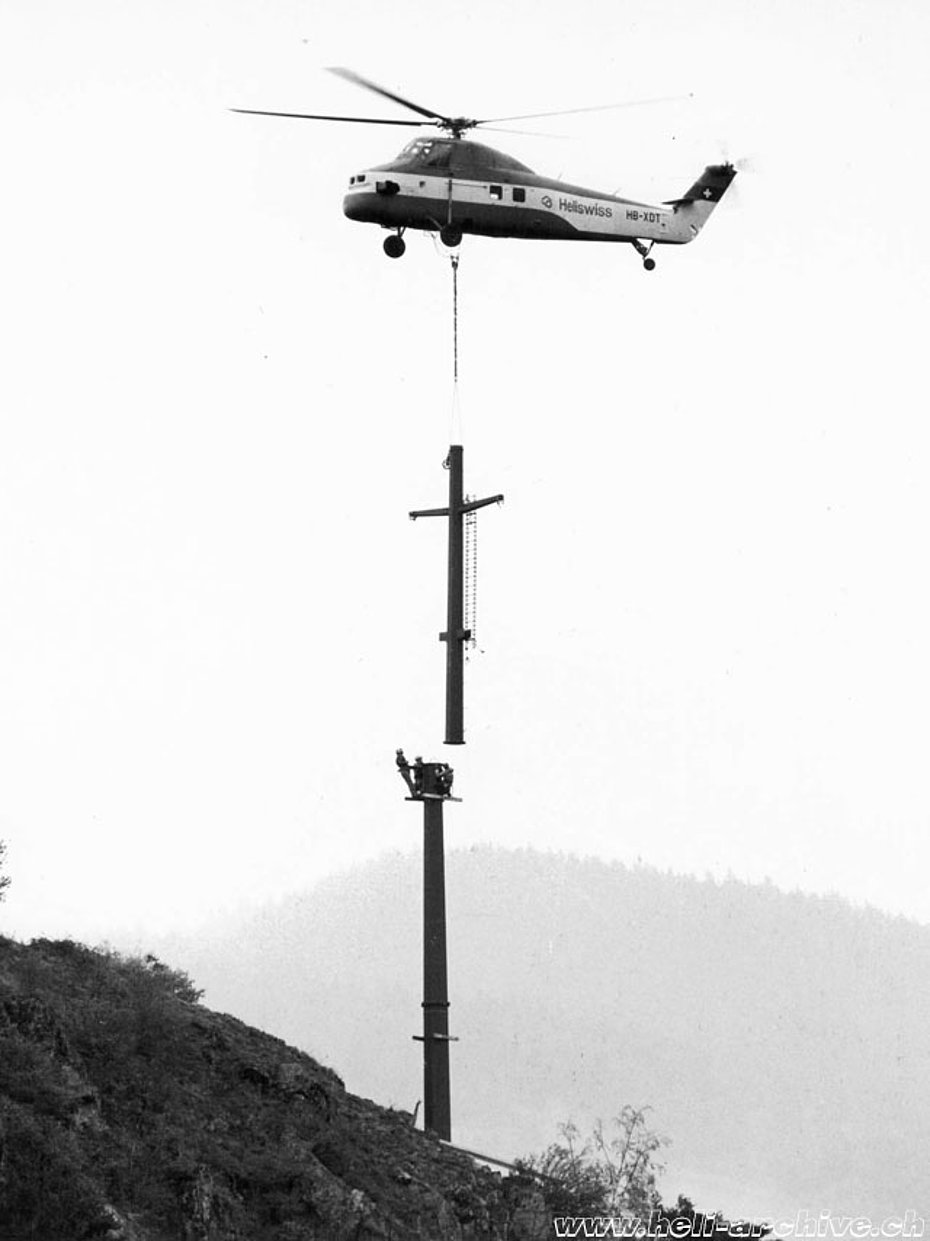

Towards the end of the 1960s, Heliswiss started a new type of activity, the aerial assembly of antennas and high-voltage pylons.

In Valtellina (a valley in the Lombardy region of northern Italy, bordering Switzerland) in April 1969, a crew of the Heliswiss assembled 120 pylons on behalf of ENEL (an Italian multinational manufacturer and distributor of electricity and gas), some of which were over 40 metres (130 ft) high.

These spectacular flights attracted enormous national and international interest. For the pilots, it was a job that required great experience and steel nerves, not least because at the time, in the absence of an effective stabilisation system and an adequate radio communication between the members of the crew, the pilot received instructions from a mechanic who hanged outside the cabin and gave him the necessary instructions with hand signs. Although primitive, thanks to a perfect understanding between pilot, observer and ground crew, the system worked.

Heliswiss’ operations centre began to receive more and more requests for all kinds of aerial assemblies. It was then that the need emerged for a more powerful helicopter with a greater lifting capacity.

In August 1970 the SA 330 Puma F-ZWWR with a lifting capacity of about 2,500 kg (5,510 lbs) was tested at Tann in Germany. However, the rental of this aircraft was quite expensive, and its purchase price of 7 million Swiss Francs out of reach for Heliswiss' finances.

The Sikorsky S-58T, the economical alternative

In June 1971, at the end of the Paris - Le Bourget airshow, the Sikorsky S-58T N8478 made a 34-day promotional tour of Europe during which it accumulated about 75 flight hours. Various demonstrations were carried out in Germany, France, Holland, Belgium and Switzerland, giving some 70 pilots the opportunity to sit at the controls. In Belp (Canton of Berne - Switzerland), one of the ten locations where the helicopter was officially presented, it captured the attention of Heliswiss.

With similar performance to the SA 330 Puma, the Sikorsky S-58T cost less than half, or about 2.4 million Swiss Francs.

For this reason Walter Demuth, at the time company's chief-pilot, and his deputy Walter Tschumi, travelled to the USA to meet the manufacturer, test the helicopter and obtain more technical information. At the end of the test flights the results were deemed positive. The helicopter tested was equipped with various optional equipment and electronic that in the one to be delivered would not have been fitted, so the empty weight would have been lower, and therefore the performance even better.

The management, informed about the results of the tests, decided to purchase the new helicopter (for its purchase the shareholders on June 7, 1972 voted a capital increase from 1.4 to 3.7 million francs).

On April 26, 1972 the helicopter was ready to be delivered and therefore Walter Demuth, Walter Tschumi and Jean-Bernhard Schmid went to the USA to take officially delivery. As it turned out from the flight books the HB-XDT (this was the Swiss call sign assigned) with serial number 58-328 had previously been a CH-34A used by the French armed forces which had employed the aircraft during the conflict in Algeria.

While Demuth took care of the technical (before becoming a pilot he had been one of the first helicopter mechanics in Switzerland at the time of Air Import) and bureaucratic aspects, Tschumi and Schmid attended the theoretical and practical training course together with Sikorsky flight instructor James Kay. After four hours of flight, the latter considered that the two Swiss pilots were sufficiently trained. On this regard, Tschumi wrote that “we would have preferred to train more, especially with regard to emergency procedures”. On May 8, the two pilots passed the examination and received their type-rating. The following day, the trio returned to Switzerland on a Swissair flight.

Dispatched by ship from New York the helicopter arrived in the harbor of Antwerp (Belgium) on May 21, where it was taken over by Tschumi and Demuth.

The helicopter landed in Belp the following day after a short stopover in Luxembourg. The employees organized a small party to celebrate the arrival of the new aircraft.

In view of its entry into service a group of mechanics which included Willi Meyer, Konrad Niederberger, Edi Krebs, Hansruedi Gasser and Ueli Huber (along with them there was also Matthey Grünenfelder, at the time apprentice mechanic) attended a four weeks maintenance course in Belp.

On May 26, on the occasion of the Alpar company open day, the HB-XDT carried out passenger flights and lifted a VW minivan. The programme also included the drop of 10 parachutists from an altitude of 2,000 metres (6,550 ft). About four minutes after taking off, the cockpit and cabin were suddenly invaded by thick smoke. Tschumi, startled, opened the window and was reaching for the fire extinguisher when the mechanic Ueli Huber, who was in the back, leaned in between the two cockpits and shouted "nothing is burning, nothing is burning, a parachutist has inadvertently lit a smoke grenade!".

Tschumi probably feared for a moment that he would burst into flames at the controls of the new helicopter! It took him a long moment before the fright passed. As we will see, others soon followed this first misadventure.

Failures and surprises

Since its arrival in Switzerland, the “Delta-Tango” was employed as a “workhorse” to perform transportation of building materials in the Swiss Alps. In addition to these, it was also used to carry out aerial erection of antennas, avalanche shelters, laying of bridges, footbridges and prefabricated structures.

In 1973, between July and October, it transported thousands of tonnes of concrete for the construction of the 10-kilometre-long power line Riddes-Verbier-Le Châble. The concrete was transported in a 800 litres (28,25 cubic feet) capacity bucket. Depending on the altitude, the helicopter lifted between 1,500 (3,300 lbs) and 1,700 kg 3,750 lbs).

On August 8, 1972, Tschumi lived a bad experience while setting in position about fifty poles in the Schwyberg region, west of the Schwarzsee. Each pole weighed 1,600 (3,520 lbs) to 2,000 kg (4,410 lbs) and had to be laid directly into the foundation. Assistance from the ground was provided by Hansruedi Gasser and Ueli Huber, while Willy Wägli gave him the necessary instruction by hand signs. After setting in position some poles suddenly the engine fire warning light lit. On the strength of his experience Tschumi hesitated a moment before pulling the famous T handle. A quick check of the instruments confirmed that everything was normally functioning. Further confirmation came from Willy Wägli and by radio from Gasser who told him that he could see no smoke coming out. A technical check revealed nothing abnormal, what further unnerved the pilot "but how reliable are these instruments?" asked himself.

As he prepared to set in position another pole Tschumi was again surprised when the “prim servo press” warning light lighted. Shortly after the flight controls stiffened and required great force to be moved.

Unable to keep the helicopter in a stable hoovering Tschumi moved to the side and released the load, hoping not to hit anyone. In those frantic moments he informed by radio Gasser of the problem, knowing however that he could not do much to help him. Using all his muscle force Tschumi managed to land without damages. After shutting down the turbines and getting out of the cabin, he noticed that the helicopter was dirty with hydraulic oil. The two mechanics after opening the cowlings noticed that the hydraulic oil tank was almost empty and a hose was broken. After its replacement accomplished on the spot, work resumed the next day.

Tschumi then slowly gained again confidence in the S-58T, but it did not last long. A few hours later he was again surprised by the same problem when another tube broke. Although discouraged the pilot was left with nothing to do but resume his work.

During a subsequent inspection it emerged for whatever reason the tubes had broken. During the overhaul work done in the United States, perhaps to save money, the old tubes of the hydraulic system had been disassembled and then reassembled. The pilot about this episode wrote, "With this badly done work then they send us pilots into the air!" (from the German language - mit einem solche Pfusch schickte man uns Piloten in die Lüfte!).

Of an entirely different kind was the problem experienced the following October during the construction of a ski lift in Cervinia (Aosta Valley). At the end of a long day's work the helicopter during the overnight was left outdoors and covered. The blades were secured as usual with ropes. The next morning upon their arrival Tschumi and the mechanics had a shock when they saw that one of the main rotor blades was completely bent and was touching the ground! Speculations about what had happened piled up, but the responsible were never identified.

All that was left for the crew to do was to call the office in Belp and arrange to send a spare blade that arrived on site the same day. Immediately repaired, the helicopter resumed the work the next day.

That same year (1972) HB-XDT was used in the canton of Graubünden to experimentally perform logging transports, the results of which, for various reasons, did not fully convinced the contractor.

On June 15, 1974, the Sikorsky S-58T was deployed for a truly delicate mission. The German railways asked Heliswiss to provide the installation of 24 new lighting masts for the Frankfurt station. Each weighing 3.6 tons, they first had to be cut in two and then reassembled.

The work, which was carried out without interrupting the trains traffic, would have taken several weeks by conventional means.

Thanks to a perfect teamwork, the assignment was completed in only 5h45' to the great satisfaction of the customer. The flights, which were followed with great interest by the press, allowed Heliswiss to gain excellent publicity.

According to a fee schedule published on June 30, 1974, the operational costs of the Sikorsky S-58T HB-XDT are resumed as follows:

- CHF 41.00/min flight training;

- CHF 51.00/min transfer, passengers and rescue flights;

- CHF 61.00/min material transportation;

- CHF 71.00/min aerial assemblies (+ 300.00 CHF/day for a supplemental mechanic)

Employement in the Swiss Alps

During the frequent mountain employments the S-58T's performance proved to be below those forecasted by the charts provided by the manufacturer in the flight manual. On this regard Tschumi wrote, "the S-58T was fitted with an old type of rotor, certainly not designed for the great altitudes of the Swiss Alps. The empty weight of our aircraft was also not that the American engineers had forecasted. Because of its lack of power I got my first gray hairs!" he used to recall.

Hansruedi Gasser remembers that one of the first episodes that evidenced this problem occurred on the Kleine-Scheidegg when the helicopter carried a large tank with difficulty. To try somehow to overcome the problem sometimes transports were scheduled early in the morning, or during the winter period when the air temperature was colder and thus the helicopter performance better.

After gaining sufficient flight experience on this model, on June 12-13, 1974 at the urging of Heliswiss, Sikorsky Aircraft sent test pilot Armstrong to Switzerland to accompany Tschumi to perform some high-altitude tests. These took place on the Männlichen (Bernese pre-Alps) at an altitude of 2,300 meters. At the end of the tests the laconic answer of the American pilot was the following: “I know about the problem”. It thus emerged that someone had tinkered with the performance charts for the purpose of embellishing them and making it more attractive in the eyes of potential customers who wanted to buy the helicopter. Armstrong, who lost his life a short time later in an aviation accident, had a copy of the original performance graphics with him (someone joked that these were secretly kept in Stratford) and as Tschumi wrote they were decidedly less attractive than those supplied with the helicopter!

This explains why in Heliswiss advertisements the maximum lifting capacity of the helicopter was corrected several times: from the initial 2,300 kg (5,070 lbs) it was reduced to 2,200 (4,850 lbs) later 2,000 (4,410 lbs) and by the end to 1,960 kg (4,320 lbs).

Resigned to the evidence, Heliswiss decided to find more suited jobs to the S-58T's characteristics. Not finding them in Switzerland the helicopter was therefore deployed abroad, for example in Tunisia, Egypt, Algeria and Saudi Arabia, where among other things it operated with a Muslim pilot trained by Heliswiss because flying activities in the Mecca region were forbidden to Christians.

For offshore operations HB-XDT was fitted with IFR instrumentation and equipped with special pop up self-inflating emergency floats mounted on the wheel hubs, while a permanently inflated float was mounted in the tail cone.

As pointed out by Hansruedi Gasser in the deployment in desert climates and during offshore operations the compressor blades, which were particularly prone to surface deposition of impurities such as dust and saltiness, required periodic washing to restore their normal efficiency.

In fact the compressor is the component that affects turbine performance the most. Therefore, it is very important that it is always perfectly efficient.

At the end of 1975 it was necessary to overhaul the two engines.

During the first five years the helicopter logged a total of 1,682 flight hours, with an annual average of 336 hours, few considering the investment.

In 1976 the helicopter was used for a special assignment, the transportation of U.S. Secretary of State Henry Kissinger.

The HB-XDT was employed almost everywhere in Europe. For example it was used for offshore operations in the Bay of Biscay with crews from the Spanish company Helicsa. In Norway it was stationed at Bödo airport and briefly used to perform passenger transportation between the islands Varoe and Røstlandet in Nordland county.

In addition to Walter Tschumi and Jean Bernhard Schmid over the years several pilots flew at the controls of the HB-XDT, among them French-Canadian Mike Zimmer, Pierre Dumont, and Austrian Heinz Kollowrath employed by Heli Austria.

The daring escape from Egypt

The HB-XDT in March 1980 was stationed at Cairo International Airport where it was scheduled to be used to make scenic flights around the pyramids of Giza, Egypt's most important and oldest monument. Having gone into business with a phantom airline company known as Gramco Airways, Heliswiss ran the risk of never seeing his aircraft again.

Sniffing out the fraudulent intentions (the Egyptians accused Heliswiss of illegally importing the helicopter without clearing customs) the operator’s executives organized an escape plan to get it out of the country as quickly as possible.

Heliswiss pilot Jacques Lampérière asked an Egyptian pilot friend to help him in the undertaking worthy of an action movie. The crew, violating the instructions, took off and headed for the harbor of Alexandria where a ship bound for France was waiting for them.

Despite the understandable apprehension (Hansruedi Gasser who was on board recalls that the military scrambled jets that intercepted the helicopter and somehow tried to intimidate them into landing) everything went smoothly.

Two other SA 315B Lama that had also been sent in the region to perform aerial treatments, and to direct the ships in the harbor, with a pretext were disassembled in a hurry and after being loaded onto a Herkules C-130 were brought back to Switzerland.

In 1981 the outbreak of war in Lebanon led to the cancellation of a contract.

In that difficult period following the oil crisis that began in 1979, where among other things there was growing international competition, the Swiss operator decided to focus more on the domestic market.

It was therefore increasingly difficult to find new employments for the large helicopter, which continued to operate under Swiss registration until the summer of 1983 when it was sold to its new owner in the United States. On July 6 it was deleted from the Swiss aircraft register.

Used by California-based Aris Helicopter, it flew for some time with the same color scheme (and the Swiss flag!) and new registration N58AH.

In 1979 Heliswiss purchased the Bell 214B-1 Big Lifter HB-XKH of which Walter Tschumi in his book speaks with great enthusiasm, but that of course is another story!

Did you know…

Westland Helicopters also developed a turbine-powered helicopter from the S-58 airframe: the first Westland Wessex HAS.1 for the Royal Navy fitted with a Napier Gazelle turboshaft first flew on June 20, 1958. Westland built a total of 356 Wessex helicopters in the various versions.

On October 5, 1962, Sud Aviation flew an S-58 experimentally equipped with two Turboméca Bastan IV turboshaft.

The prototype of the S-58T registered N8478 begun its operational career in February 1958 with call sign N421A and was used to make, among other things, a demonstration tour in Europe in 1958. It was then registered in Italy as I-AGMI for Agip Mineraria. On August 18, 1983 this helicopter while operated by Argentinian company Helicópteros Marinos S.A (LV-AOA) had an accident at Aguas Blancas, Orán, Salta. Six people lost their lives.

The Sikorsky S-58T has appeared in many movies and television series. The most famous is the pink-painted one registered N698 nicknamed "Screaming Mimi" that appeared in the U.S. police television series "Riptide," produced by NBC from 1983 to 1986 over three seasons. Link

In the early 1950s, manufacturers understood that, with the possible exception of light 2-3-seat helicopters, the turbine would supplant heavy and cumbersome piston engines. Sikorsky, eager to gain experience with this new type of engine, modified an S-52-2 by replacing the original engine with a Continental/Artouste II turbine. The new prototype, now housed at the New England Air Museum in Windsor Locks, Connecticut thus assumed the designation S-59 (or XH-39) and made its first flight on June 1, 1954. While fast and innovative, this model was not successful. In fact, the US Army chose the XH-40, otherwise known as the Bell UH-1 Huey.

During the summer of 1976, Carson Helicopters was contracted by the Saudi Arabian government to unload more than 200 ships clogging the main harbor of Jeddah on the Red Sea carrying building materials in support of the largest peacetime construction program ever attempted in the region. The turnaround time for unloading a ship was 40 days at best, with some ships sitting in the harbor waiting 2 to 3 months. Forty percent of the cargo to be unloaded was bags of cement.

Carson operation launched 6 to 8 S-58T in the air operating 6 days a week, weather permitting. The aircraft were operated 12 hours per day in removing high priority cargo from the ship which were clogging the harbor. Three aircraft were in the air at all times carring 1'905 kg (4’200 lbs) of cargo on 30 meters (100 foot) slings. The helicopter made a round trip evey 3 to 4 minutes from cargo hold pickup to dock drop off.

On September 8, 1976 while this extensive operation was underway the aircraft with call sign N4371S crashed after the cargo it was lifting became entangled. In the accident the pilot unfortunately lost his life.

According to an article published in the Vertical Magazine on January 3, 2017 Brad Ladue, California Helicopter’s CEO, has over 26,000 hours of flight on the S-58/S-58T.

Acknowledgements

The author thanks Heliswiss mechanics Hansuedi Gasser, Rudolf Renggli and Matthey Grünenfelder for their valuable cooperation in providing information and documentation for the preparation of this article.

Last but not least the author apologizes for any errors or inaccuracies in any way attributable, at least in part, to documentation published more than fifty years ago. Any corrections or historical contribution are of course welcome!