The origins of the Hughes 500 series helicopters are described in detail in a separate article.

The birth of the Hughes 500D is directly linked to a helicopter developed by the Hughes Tool Company during the final stages of the Vietnam war to meet a particular request of the CIA.

The helicopter in question is known as the Hughes OH-6A/NOH-6A (later Model 500P where the P meant "Penetrator") nicknamed "The Quiet One".

This model, designed to reduce noise emissions as much as possible, was used to carry out a highly secretive telephone interception mission in North Vietnam on behalf of the CIA (photo) on December 5-6, 1971. The helicopter was equipped with a five-blade rotor, a more powerful turbine and a four-bladed tail rotor.

Later on two new versions were derived from this model both known as OH-6C, which stood out for having a five-blade rotor (for this reason the noise was considerably reduced), a new "T" vertical stabilizer, a more powerful Allison 250-C20 turbine developing 294/400 kW/shp, thanks to which the helicopter improved both the overall performance and the transportation capacity. These improvements led to the birth of the Hughes 500D whose prototype made its first test flight in August 1974, while the first production model was tested on October 9, 1975.

Differences from predecessor

The new version similar in size and characteristics to its predecessor received the commercial designation Hughes 500D (on the original type certificate number H3WE issued by the Federal Aviation Agency - FAA - the helicopter is designated Hughes Model 369) and was publicly announced in February 1975 at the Helicopter Association International (HAI) meeting in Anaheim, California.

The helicopter stood out from its predecessors for having a new five-blade main rotor, a more powerful version of the Allison 250 turbomotor (C20B) capable of delivering a maximum take-off power of 309/420 kW/shp, a new transmission capable of absorbing a maximum take-off power of 275/375 kW/shp and a maximum continuous power of 257/350 kW/shp. To improve stability the "V" shaped asymmetrical canter stabilizers were replaced.

The new D’s T tail eliminated the pitch-down noticed by the military pilots in Vietnam as well as by agricultural operators of the earlier 500s. As the helicopter banked sharply to the left, the tail tilted horizontally producting an apparent nose-down trim change.

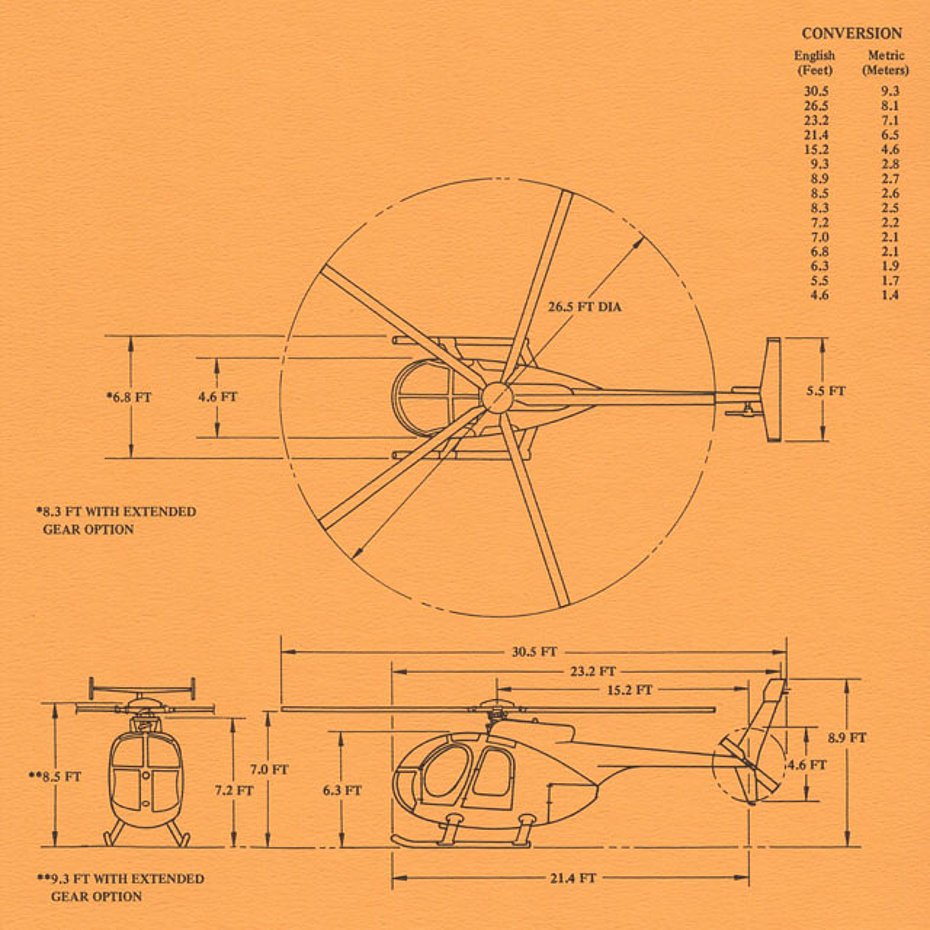

In order to ensure adequate torque control due to the increased power and the new rotor, the tail boom was strengthened and lengthened by 2 inches (about 5 cm) and the tail rotor diameter increased by 4 inches (about 10 cm) from 51 to 55 inches.

The lower part of the characteristic egg-shaped cabin was reinforced and so were the struts of the landing gear whose oleopneumatic shock absorbers were redesigned. Their pressure was increased to compensate for the increased weight. The Plexiglas panel supports in the cabin and the same panels were also strengthened as a result of speed increase.

With the same take-off weight, the new five-blade rotor proved to be quieter than the 500C model.

This quality was duly advertised by the manufacturer to promote sales in urban areas for the classic surveillance tasks carried out for example by the American Police Departments.

It is interesting to remember that by the time the new model arrived on the market, the 369/500 series had accumulated a total of more than 4 million hours of flight time, many of which had been carried out during the Vietnam conflict under very difficult operational conditions.

People at Hughes mistakenly believed that the certification of the new helicopter would not take long.

In fact unfortunate concomitant and unexpected technical problems delayed their plans.

The first big delay was caused by the accident that occurred on March 3, 1974 to a Mc Donnell Douglas DC-10 operated by Turkish Airlines departing from Paris, which caused the death of the entire crew and passengers (346 occupants in total). The plane crash, among the most serious ever happened in the aviation history, absorbed a large part of the resources of the Western Region's FAA staff and prompted the FAA to carry out even more stringent certification parameters.

On the technical side an accident occurred during transmission operation tests. Due to the failure of an incorrectly machined gear this failed, so that the 150-hour running test had to be repeated.

After successful completion of the certification program, the FAA granted the Hughes 500D the type certificate on December 8, 1976.

In February 1977, the American manufacturer announced that it had already received 250 orders. At that time the production rate was 15 aircraft per month.

On the civilian market, the Hughes 500D was in direct competition with its historic rival, the Bell 206B Jet Ranger.

In Spring of 1979 the Hughes 500D was sold at a price of USD 232,000, while the cost of a Bell 206B Jet Ranger III (produced since 1977 with the same Allison 250 C20B turbine) was USD 225,000. The 500D direct costs per hour of flight in that period were quantified by the manufacturer at USD 51.97.

Production under license

Hughes granted the construction licence for this model to the Italian manufacturer Nardi (later Breda Nardi), to the Japanese manufacturer Kawasaki (the first 500D “made in Japan” flew on December 2, 1977), to the Argentine manufacturer RACA (Representaciones Aero Commerciales Argentinas SA which, however, according to information gathered, was limited to the assembly of helicopters with components manufactured in the United States) and to the South Korean Korean Air Lines.

The latter company initially handled the assembly of civil and military models built in the United States, although the agreement provided for mass production. By early 1980's KAL had completed over one hundred helicopters. These included 75 500MD Standard Scout models (a military version of the 500D) and 25 500MD/TOW, plus a few 500D for South Korean civilian operators.

Later the East Asian company began mass production of these models and others of the 369/500 series following new agreements with Mc Donnell Douglas Helicopter Co.

By the end of 1987 over 450 units had been delivered, some of which were exported.

The Hughes 500D had a good commercial success: in June 1981 Hughes delivered the 1,000th unit.

This version remained in production for a limited period as the next version named 500E took over in 1982, while in 1983 the 530F version, very similar to the 500E but equipped with a more powerful Allison 250 C30 turbine, appeared on the market.

The MD530F was engineered to meet the requirements for hot-day, high-altitude aerial operation and according to its manufacturer operates more effectively than other helicopters in its class.

The Hughes 500 has also been produced in various armed versions for military use designated 500MD/ASW/TOW/Defender.

In January 1984 Hughes Helicopter Inc. sold its helicopters business to McDonnell Douglas, then in 1997, McDonnell Douglas merged with Boeing to become The Boeing Company.

In 1999, Boeing sold the former MD commercial helicopter lines to MD Helicopter Holdings Inc., an indirect subsidiary of the Dutch company, RDM Holding Inc. Included in the sale were the MD 500E and MD 530F single-engine helicopters with conventional tail rotors, the MD 520N and MD 600N single-engine helicopters with the Boeing exclusive NOTAR no tail rotor system for anti-torque and directional control, and the MD Explorer series of twin-engine, eight-place helicopters.

MD Helicopters Holdings Inc. was acquired in July 2005 by Lynn Tilton, founder and owner of Patriarch Partners, LLC, a family office/private investment firm.

The company was recapitalized as an independent company, MD Helicopters Inc. based in Mesa, Arizona, the current product line includes the MD 500E, MD 530F, MD 520N, MD 600N and the MD 902 Explorer for commercial applications, as well as the MD 530F Cayuse Warrior, MD 530G Scout Attack, and MD 969 Twin Attack platforms for military and paramilitary customers.

Technical description

The Hughes 500D is a five-place, single-engine, multipurpose helicopter. It has a fully articulated five-blade main rotor system and uses a two-blade tail rotor for anti-torque. An optional four-blade tail rotor is available for noise reduction. Power from the turboshaft engine is transmitted through the main drive shaft to the main rotor transmission, and from the main rotor transmission through a drive shaft to the tail rotor. A one-way clutch between the engine and main rotor transmission permits main-rotor freewheeling during auto-rotation.

The rotor is supported by a hollow static mast mounted to the primary structure that absorbs all the flight loads, allowing the transmission to provide torque only.

The characteristic "egg" shaped fuselage is a semi-monocoque structure that is divided into three main sections: forward section, cargo/passenger center section, aft or engine section.

The forward section is comprised of a pilot compartment with seats for the pilot and either one or two passengers.

The fuselage has been carefully designed to be as aerodynamic as possible.

In the front, under the floor, there is a space housing the electrical system, the battery and part of the avionics.

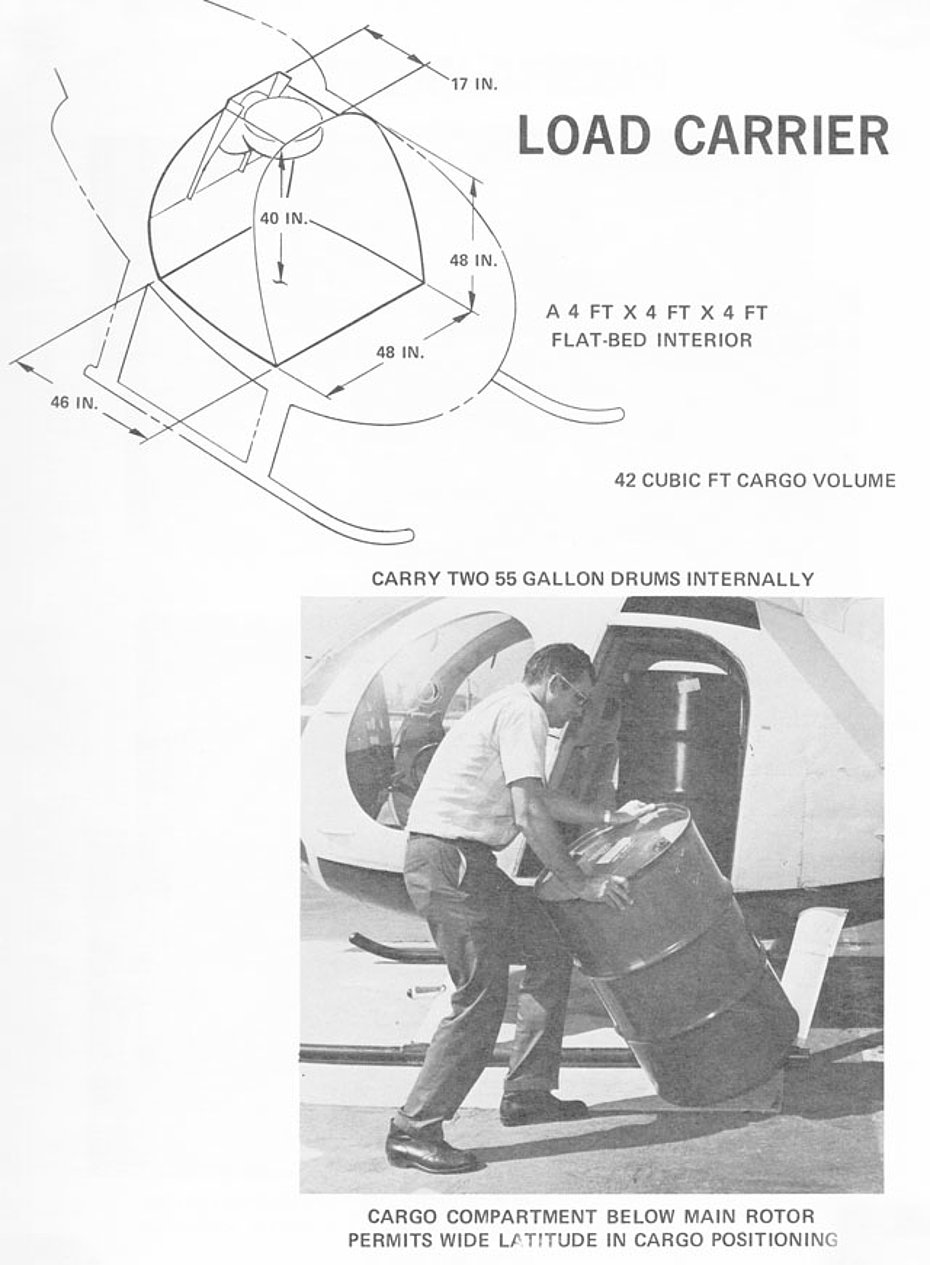

The second section is the central cargo/passengers compartment whith a volume of 1.18 m3 which offers space for two passengers.

To highlight available internal volume, advertising photographs released during the 1970s often show two standard 208 litres (55 gallons) fuel drums in this compartment.

In this section, upon request, a special platform could be installed, to carry, for example, four workers or four firefighters placed one in front of the other with crossed legs.

Below this compartment there is the 242 litres capacity double wall fuel tank.

The engine section houses the turbine and is separated from the passenger compartment by a firewall.

The semi-monocoque fuselage is manufactured primarily of aluminum alloy. The basic structure is formed by a sturdy central A-frame truss with integral seat which provides “roll bar” protection for passegers, crew and cargo.

The landing gear legs equipped with shock absorbers are fixed directly to this structure.

Access to the cabin is possible through four doors, two on each side. The instrument panel is centrally mounted at the front and houses the flight instruments and radio equipment.

Ventilation of the cabin is manually controlled through a vane valve located in front of the cabin. Openings in each door allow airflow to be controlled.

On this model the new soundproof coating helps to reduce internal noise. Thanks to the elimination of the internal cooling of the transmission, passenger comfort is also improved by the fact that they have slightly more headroom.

A device for heating and defrosting the cabin windows is available upon request.

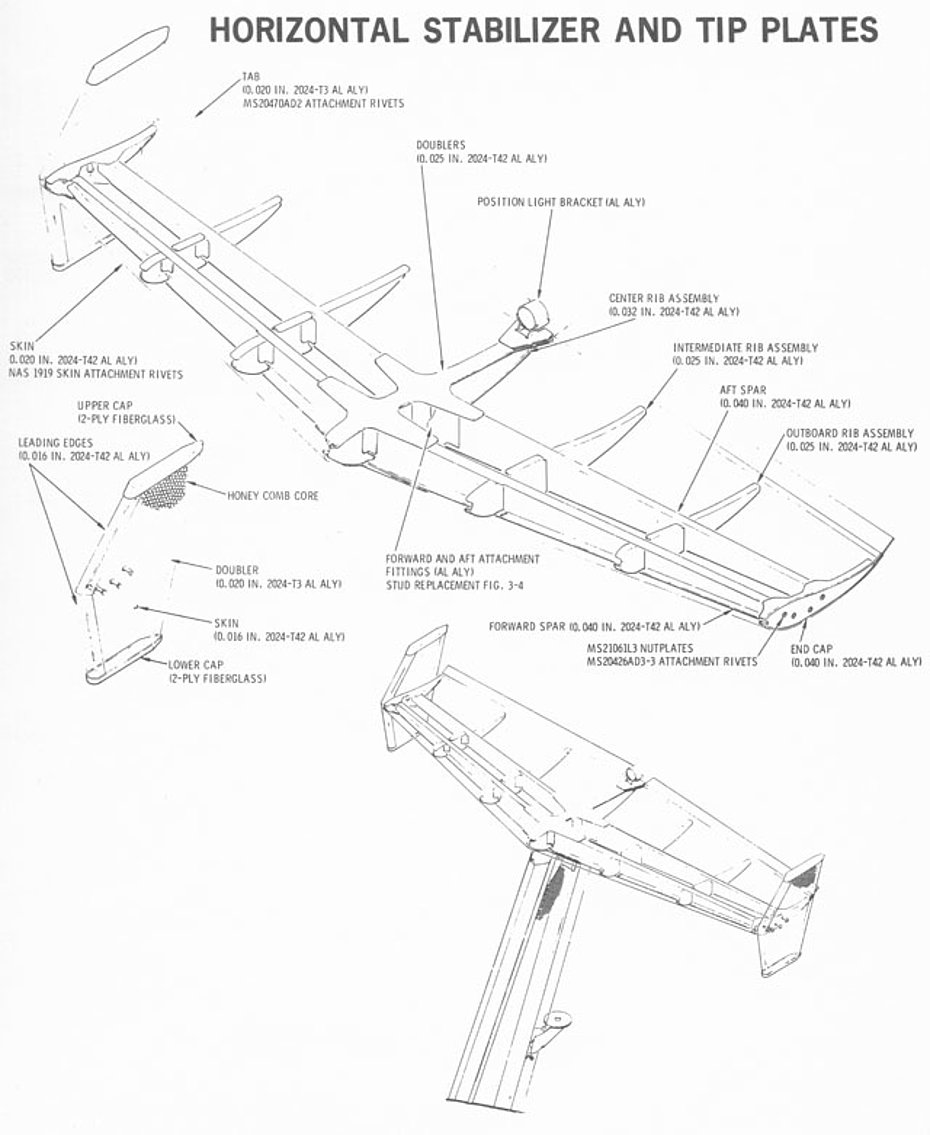

The tail boom is attached to the centre section and supports the tail rotor and T-tail. The latter has an aluminium-coated honeycomb core structure. On the bottom there is a bumper. The horizontal stabilizer is of conventional wing design with ribs and spars, and is set at a positive 5 degrees, but providing negative lift. Between the stabilizer and the tip plates there are two weights used to detune the tail. The tip plates have a honeycomb core with a fiberglass cover.

The legs of the landing gear (high or low at customer’s choice) are fitted with aluminium aerodynamic fairings.

The skid tubes are heavier wall (0.090 inches thick) and incorporate a new pivotal mounts at the aft strut attachment points. This prevents torsional twist of the landing gear skid tube and aids in prevention of a tail boom chop during excessively hard landings. Steel plates underneath the skids prevent excessive abrasion.

Rotor, transmission and controls

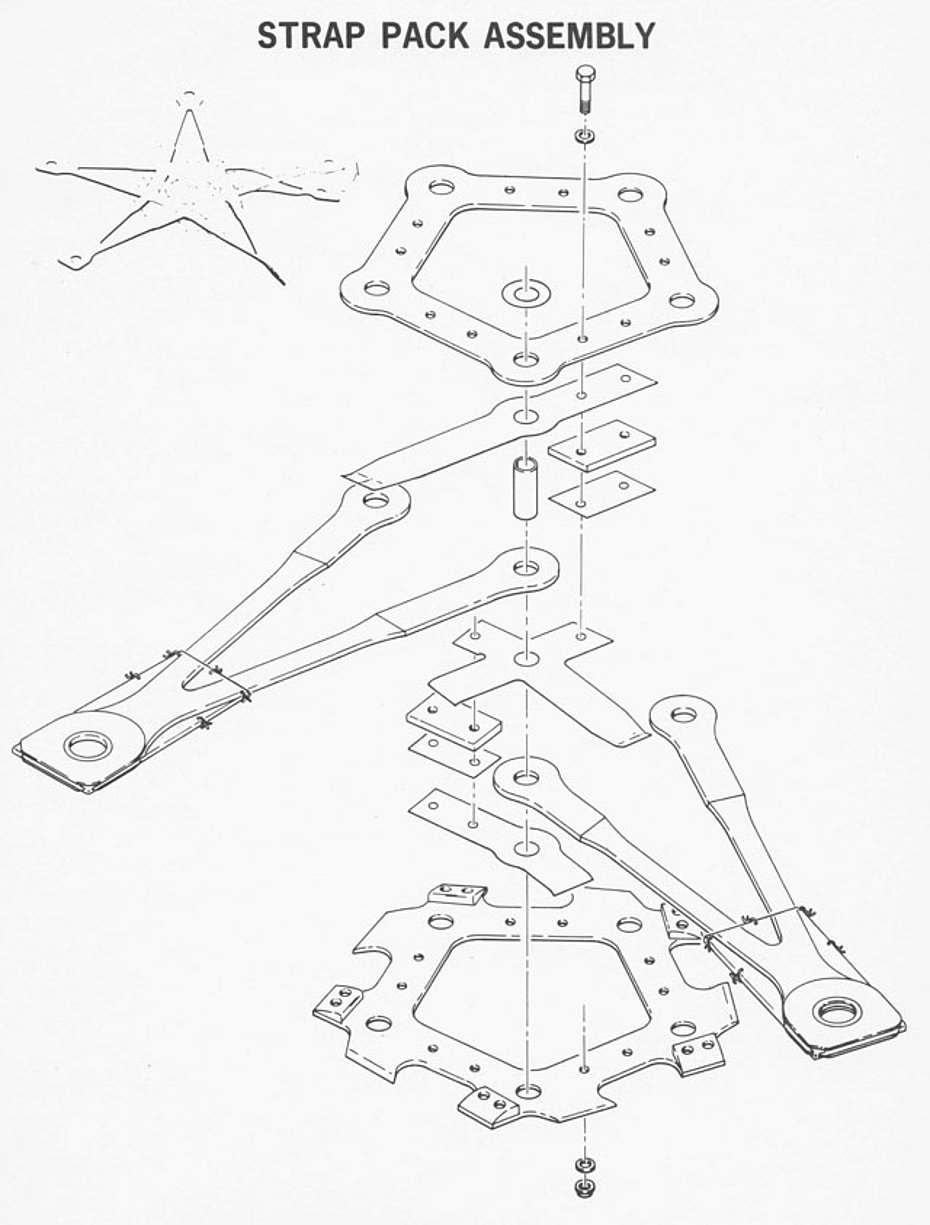

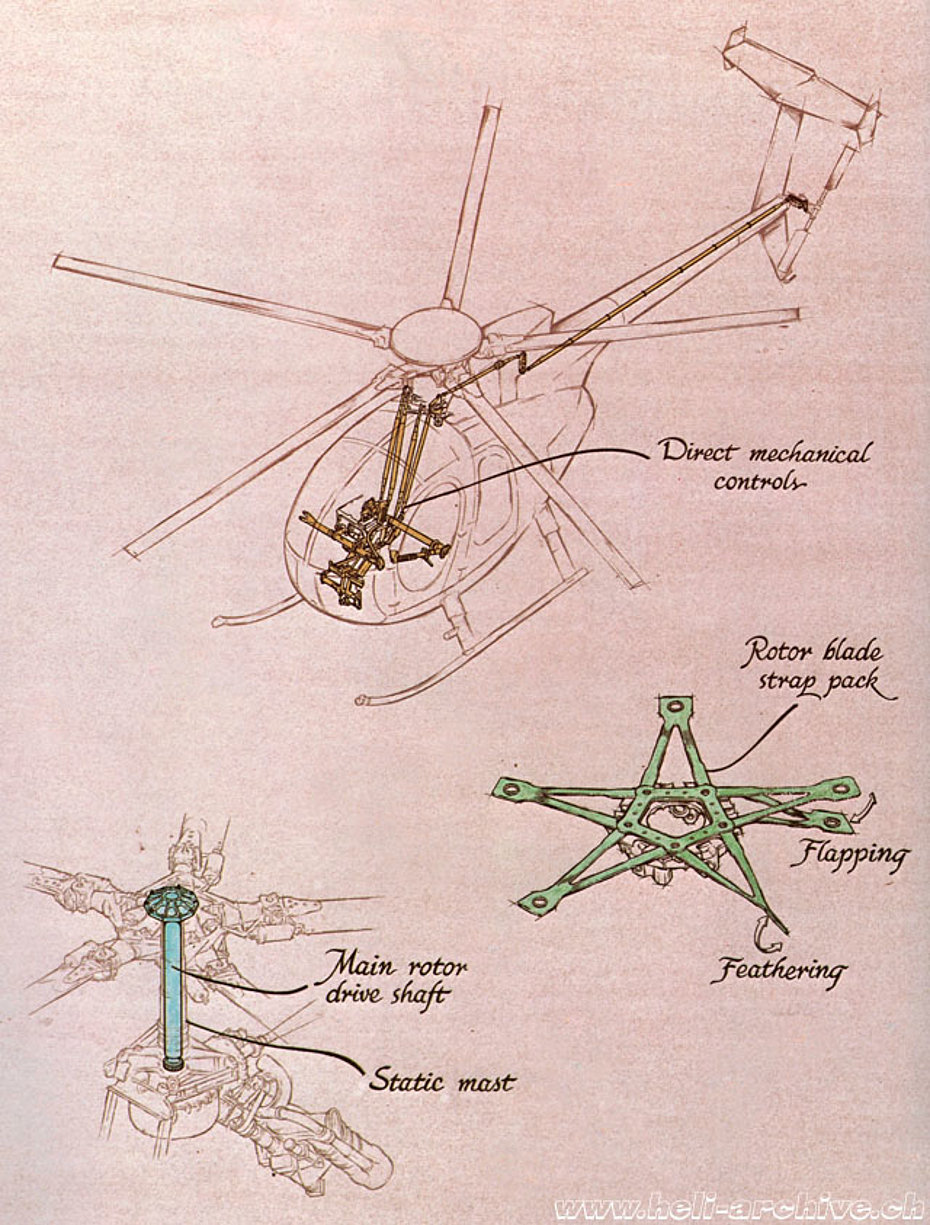

The Hughes 500D utilizes a fully articulated five-blade rotor hub retaining the strap pack concept but having five individual “V” shaped strap packs, main rotor assembly. Rotor blades, pitch housings, and links are secured to the hub by laminated steel strap sets.

These sets are used in place of typical thrust bearing stacks to contain blade centrifugal loading and allow feathering.

This system known as the "Flexrotor" was developed by Hughes' engineers and uses flexible strap packs each containing high-strength stainless steel straps to support the rotor blades. These straps allow the blades to flap or to vary in pitch angle as illustrated.

This design had already given excellent results in terms of simplicity of construction and maintenance on the 500C series.

Also with regard to the rotor, it is interesting to note that the change from four to five blades did not lead to an increase in weight because the original shock absorbers were replaced by other lighter elastomeric lead-lag dampers in place of the heavier friction dampers employed in earlier 500 models.

The slight increase in rotor diameter is due to the fact that the main rotor hub is one inch wider.

In cruise flight the fully articulated main rotor turns at about 490 rpm and emits a noise (or a sound dependending from the point of view!) that makes it immediately recognizable.

The main rotor blades (originally their TBO was 2,500 hours) have been modified compared to previous models. Internal ribs have been added.

The static mast-hub support system, unique to the Hughes 500 series, uses a static mast, rigidly attached to the fuselage.

All dynamic loads are transmitted through the mast, rather than through the transmission. The primary structure absorbs all the flight loads, allowing the transmission to provide only torque. A separate, inner drive shaft transmits engine torque to the main rotor hub. This feature offers improved flight control integrity and helps retain rotor system components in the event of a main rotor blade strike. Additionally, this approach allows for the design of a main transmission that is lighter in weight and can be removed without disturbing the hub or control system.

The main transmission has been redesigned and incorporates stronger gears and housings, new oil pumps and bearings. The cooling system has also been changed and does not require a separate radiator.

The cooling fan conveys more cooling air (about 40% more) to the engine and transmission oil cooler.

New air inlet fairings are without air scoop that formerly were used to cool the main transmission. The cooling air is intaked aft of the mast support structure.

The engine cowlings were notched to evacuate air from the engine compartment.

The oil cooler blower has wider belt and pulleys and a new ducting fan.

The two-blade tail rotor, with metal blades, is driven by a single transmission without bevel gearboxes, couplings or intermediate bearings. Mechanical complexity, weight and obviously maintenance are therefore reduced as already mentioned.

By the mid-1980s, the manufacturer gave operators the option of mounting a four-blade “scissors type” tail rotor for quieter performance.

By reducing the rpm by 25%, the noise was reduced by almost 50%.

The flight control system consists of a conventional helicopter control system for collective, cyclic, and anti-torque tail rotor control. The cyclic and collective control sticks incorporate friction devices as a method for the pilot to vary movement friction and the amount of effort required to move the control sticks. The cyclic stick lateral and longitudinal movement friction is adjustable. The collective stick vertical movement friction and the throttle twist grip movement friction are adjustable. The collective stick throttle twist grip can also be locked when the operational gas producer turbine speed is attained. The copilot flight controls can be easily removed to provide room for passengers or cargo.

The range of the controls is significantly greater than the previous version and this is due to the increase in speed, weight and the addition of a blade.

Engine and transmission

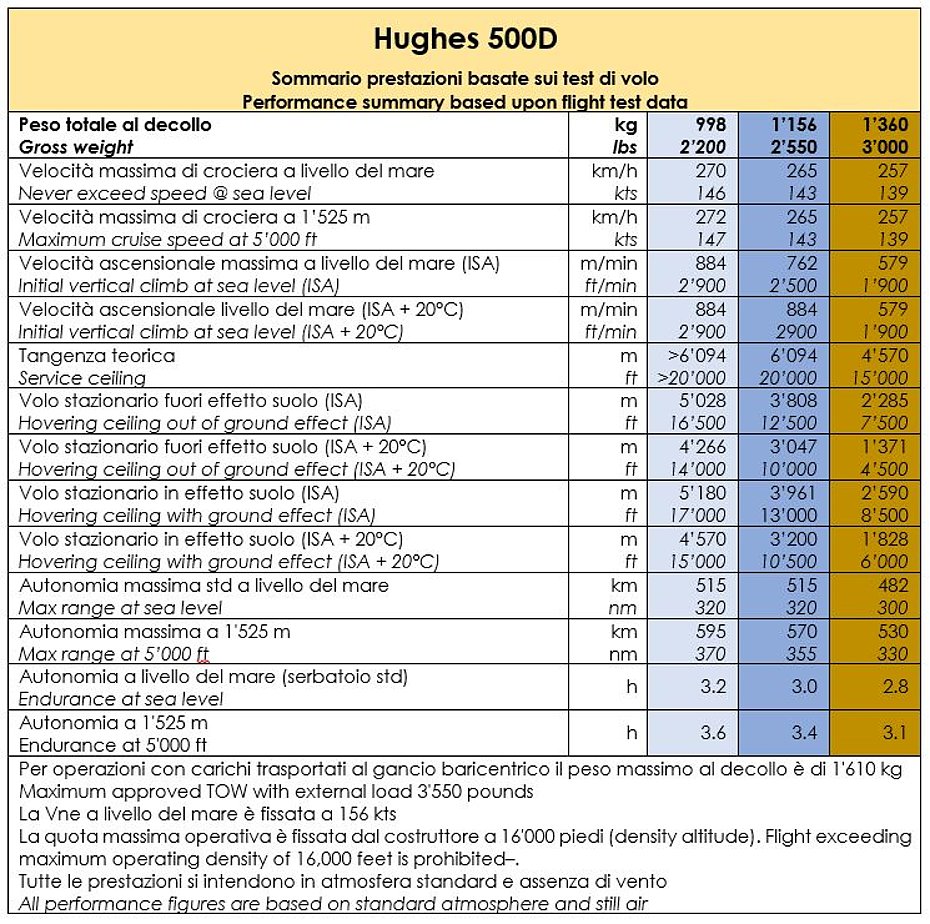

The engine used in the Hughes 500D is the Rolls-Royce (Allison) Model 250-C20B gas turbine engine that produces 309/420 kW/shp, derated to 275/375 kW/shp for takeoff, and 257/350 kW/shp at maximum continuous operation. It is equipped with a Bendix fuel control unit.

This compact and lightweight engine, weighing approximately 72/158 kg/lbs, is an evolution of the previous models of the C18/C20 series, which in turn were derived from the T63-A-5 developed on behalf of the US Army from June 1958 for the new LOH helicopter.

The helicopter incorporates a modified auto-relight ignition system (in case of flame out).

The hourly average fuel (kerosene) consumption is about 100 liters/26.4 USG.

The turboshaft is mounted at the rear with an upward inclination of about 45 degrees. It is protected by two hinged doors that can be opened outwards. In this way it is not necessary to climb up the fuselage for engine inspection. If necessary, the engine can be replaced without the aid of a crane.

The tail rotor transmission is heavier and incorporates new shafts, gears and new seals that are easily replaced. Bearings were upgraded.

At customer’s choice the Hughes 500D can alternatively be equipped with a 335/450 kW/shp Allison 250 C20R/2 turboshaft.

Optional equipment

The Hughes 500D can be equipped with various optional equipments. The list includes: optional seats for the transportation of 7 occupants (four seats with safety belts on the floor), 2 individual rear folding seats, dual controls, 272/600 kg/lbs cargo racks on both sides of the fuselage, 227/500 kg/lbs cargo pod, cargo hook for the transport of suspended loads (maximum capacity 907/2,000 kg/lbs), various agricultural equipments (Chadwick, Simplex, Transland), internal auxiliary tank (capacity 35/132 USG/litres add 55% more range and endurance), external tank (capacity 44/166 USG/litres), self-sealing fuel tank, engine air filter, litter kit with two stretchers, extended landing gear, snow skis, utility floats, emergency floats, law enforcement kit, rotor brake, electric hoist (136/300 kg/lbs lifting capacity), blade folding kit, Chadwick fire fighting kit, additional instrumentation and avionics, on-board computer (originally the helicopter was equipped with an HCS-500 computer that monitored the aircraft data during flight), heating and defrosting system.

Civil use

The great versatility and the excellent flight performance of the Hughes 500D has allowed it to achieve good commercial success. Among the main tasks performed by this machine are: transportation of passengers and freight, surveillance and patrols (in Italy users include the State Forestry Corps – Corpo Forestale dello Stato and the Guardia di Finanza), aerial treatment of cultures, aerial photography and filming and pilot training.

Among those who chose this versatile helicopter for their commercial services in addition to operators offering the classical services were large oil companies offering offshore services.

In the meantime, some of these helicopters have been replaced by others better-performing and with more cabin space, such as those in the AS 350 Ecureuil series.

The empty weight in the standard configuration is 617 kg (1,360 lbs). The maximum take-off weight with internal load is 1,360 kg (3,000 lbs), while with a slung load the maximum take-off weight is 1,610 kg (3,350 lbs.). Although some advertising photos show the helicopter lifting a car weighing one ton, the helicopter usually carries loads weighing approximately 500 kg (1,000 lbs).

The Hughes 500D in Switzerland

The first Hughes 500D arrived in Switzerland in 1977. The first to receive a Swiss call sign was the Hotel Fox Romeo (HB-XFR) purchased by Robert Fuchs.

From February 6, 1976, this historic operator was authorised by the Federal Office of Civil Aviation (FOCA) to carry out commercial transportation and the maintenance of its aircraft. In addition to the aerial transportation of passengers and freights, the Swiss operator started almost immediately to act as the general representative for Switzerland, the Principality of Liechtenstein and Austria for the Hughes 269 and 369 series.

Almost all the helicopters in this series registered in Switzerland therefore passed through the heliport of Schindellegi and this was certainly no coincidence. Several helicopters were registered for a short time (in some cases even a few days or weeks) before being sold in Italy as “second-hand” aircraft (the list includes I-MONG, I-SMAR, I-GETI, I-KURZ, I-METT, I-EVIT, I-ELIP, I-DEBO, I-COLA carried previously a Swiss registration), and this in order to circumvent a constraint according to which new aircraft could only be delivered in Italy by Breda Nardi Costruzioni Aeronautiche SpA based at Milan-Linate airport (otherwise known as Forlanini Airport in homage to the Italian aviation pioneer Enrico Forlanini 1848-1930) which manufactured under license this series.

One might therefore think that the price of the aircraft sold in Italy was higher or that the delivery times were too long, that's why it was more advantageous to buy one from Switzerland.

Transportations

Fuchs Hughes 500Ds were mainly used to perform classic tasks such as pilot training, transportation of people and freight, aerial photography and television filming between the late 1970s and 1980s. They were later replaced by the new 500E and 530F version manufactured by McDonnell Douglas.

Heli Tamina

Founded in 2014, this young company headed by Remo Niederer uses the Hughes 500D HB-ZRL to provide a multitude of aerial services in Central and Eastern Switzerland.

Based at Mollis/GL airport, the helicopter generally piloted by Niederer himself is used for general aerial services. Among the main operations carried out are: transportation of people and materials, supply of huts and mountain pastures and aerial assembly.

The "Zebra" (nickname given to the helicopter because of its paint scheme) is also used for somewhat special missions such as artificial avalanche detachment or forest fire fighting.

Reto Niederer in very proud of his Hughes 500D and says that the performances of the helicopter are really remarkable considering the power developed by the Allison 250 C20B. The helicopter can carry slung loads of about 500 kg.

A dynamic team and competitive prices have allowed Heli Tamina to grow and gain the trust of a crescent number of customers.

For more information about this Swiss operator please visit the website www.helitamina.ch

Breda Nardi Costruzioni Aeronautiche SpA

The Hughes 500 was marketed in Italy by Fratelli Nardi SA Costruzioni Aeronautiche, an Italian aeronautical company founded in 1934 in Milan by the brothers Euste, Elio, Elto and Luigi Nardi. The company was based at Milan-Linate airport.

In 1969 thanks to an agreement with the American manufacturer, the Italian company obtained the manufacturing license for the 369/500 and the 269/300 series helicopters. In order to promote the sales, in 1967 Hughes sent to Italy a demonstration aircraft that received the call-sign I-NARD.

Initially, the Italian manufacturer was mainly involved in the assembly, maintenance and repair of American-made aircraft.

Production of the Hughes 500D was scheduled to start in 1978 in both commercial and military versions.

The construction of the 500C and 300C models was undertaken in a factory with a surface of 20,000 square meters in Monteprandone near Ascoli-Piceno. Here were manufactured under the designation Nardi-Hughes, the 500Ds supplied to the State Forestry Corps and the Guardia di Finanza.

In the 1980s the activity and its structures became part of the Agusta Helicopter Division. Once the deliveries were completed, the production ceased and the company was forced to close its doors in autumn 1991. From one day to the next about 500 employees lost their job.

The opinion of an expert…

According to the eminent aerodynamic expert Raymond W. Prouty, author of many books (among them Helicopter Aerodynamics) and articles related to the complex topic of helicopter aerodynamics, the T-tail used on the Hughes 500D is structurally inefficient. Furthermore, because of its weight and location, the T-tail is subject to different vibrations generated (or excited) in forward flight by the main rotor downwash.

When the 500D was being designed it was decided to use a T-tail primarely because it looks better. The T-tail has proved to be satisfactory on this model because of the rotor disc load being relatively low.

The Hughes 500D on video and television

Probably the most famous Hughes 500D is the one that appears in the popular 1980s television series "Magnum P. I.". - www.youtube.com/watch

Due to its small size and manoeuvrability the Hughes 500D is used in the construction and maintenance of power lines, a stressful and dangerous job that requires nerves of steel: https://www.youtube.com/watch?v=6_NEAEGeFIw

Alpenair's Hughes 500D piloted by Werner Kurz at work in the Austrian Alps in 1991 on behalf of the Austrian Television Company ORF during the FIS Alpine World Ski Championships in Saalbach: https://www.youtube.com/watch?v=sPg3zHQXTb8

In 1983 the Hughes 500D piloted by Jim Fowler is used to draw red deers from an overcrowded area in New Zealand: https://www.youtube.com/watch?v=iTNxKwrKpUw

Recommended readings

Loach! The story of the H-6/Model 500 helicopter by Wayne Mutza - ISBN 0-7643-2343-1

The book traces the history of the OH-6/500 series helicopters and contains many interesting and historical photos.

Did you know that...

In 1981 Hughes Helicopters announced at the Paris Air Show that it was seriously considering adding a new 6 seats helicopter derived from the 500D. However a final decision had not yet been taken.

According to the data disclosed, the autonomy would have been increased by almost 50%.

The model 600X retained the power plant and transmission of the Moel 500 D but the airframe incorporated a 38 cm (15 inc) widening of the standard cabin, providing 75 percent more headroom. It was estimated that range and endurance would be 49 percent greater than the 500D.

HAB 04/2020