Hughes 269B - History and technical description

Some historical notes

The Hughes 269B (also known with the commercial designation of Hughes 300), is an evolution of the 269A and 269A-1 models (for additional information about these versions please consult the in-depth article "hughes-269a") manufactured by the Aircraft Division of the Hughes Tool Company of Culver City (California).

Although it was expressly developed as a two-seater to meet the specific needs of the civil market, the 269A almost immediately underwent a makeover during which it was transformed from a two-seater into a three-seater.

To achieve this objective the American technicians slightly rearranged the inside part of the cabin.

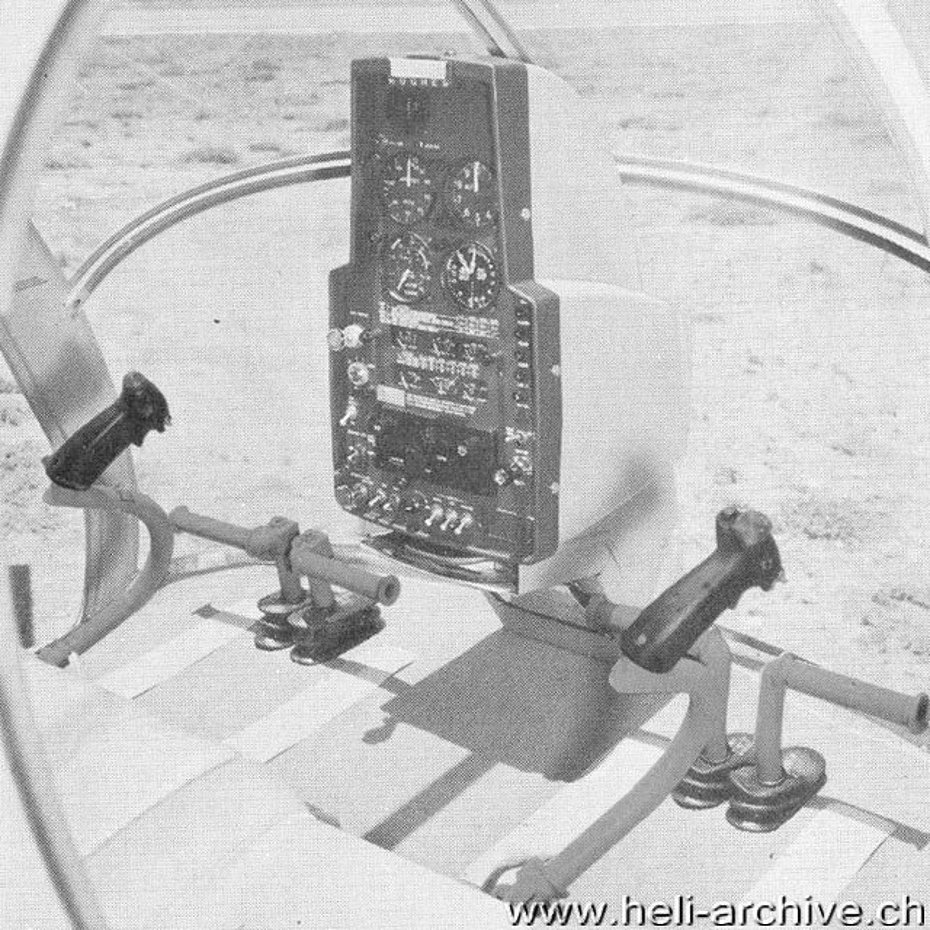

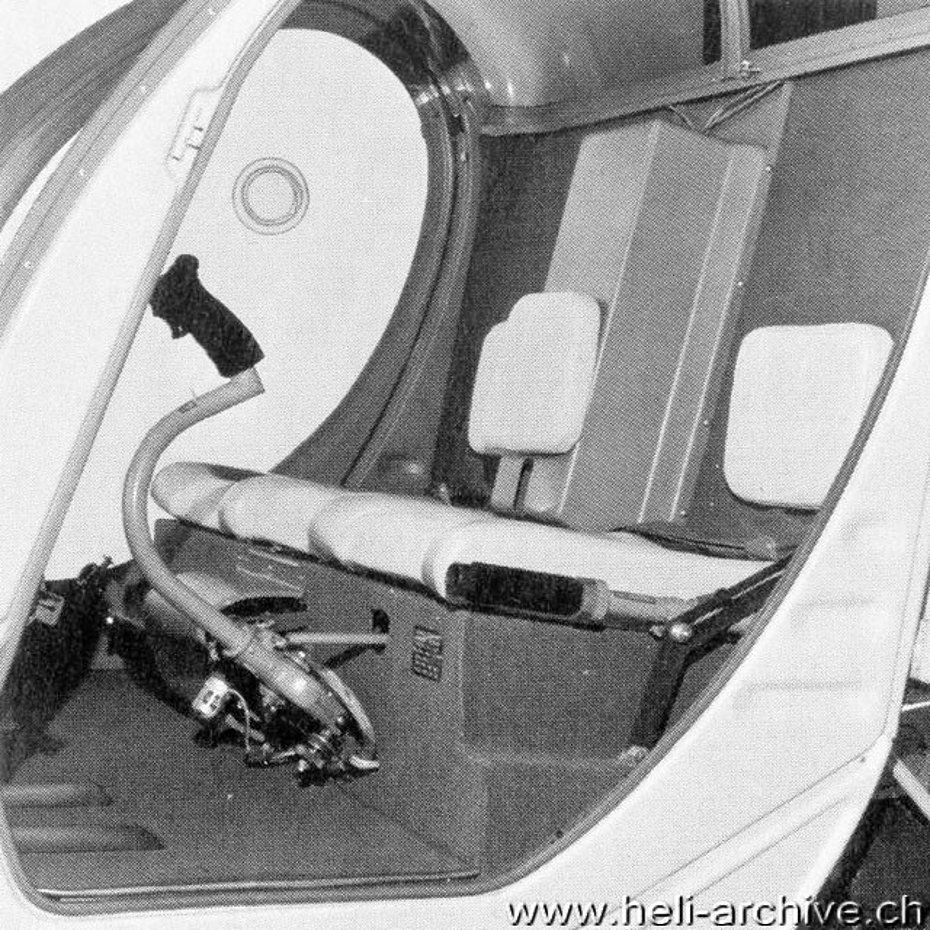

The instrument panel was redesigned and located further forward while the controls were relocated to create space for a second passenger who seats centrally, and whose position is slightly advanced to that of the pilot (seated to the left) and the right hand passenger.

Other new features of this model are the electric rotor engagment and the fuel injected Lycoming HIO-360 engine which offers many benefits, the first of which being undoubtedly the reduction of carburetor ice risk. Other advantages of the injection system are: improved engine response to pilot inputs, better combustion (and therefore reduction of pollutant emissions), uniformity in supplying the fuel mixture in the cylinders, which automatically leads to a reduction in fuel consumption in cruise flight and a better cooling.

On the aerodynamic side, Hughes have cleaned-up the blade profile, incorporated stainless steel, hard-anodized leading-edges and increased blade diameter but just over three inches, all of which give better lift and autorotational performance.

Handling has been improved by the incorporation of electrically controlled cyclic trimming in combination with simple friction dampers applied individually to lateral and longitudinal cyclic axes, as well to the lever and twist-grip.

To increase the versatility of the helicopter several new accessories such as floats for amphibian use, stretchers for the transport of lying injured, cargo-racks and cargo sling were developed.

The 269B version obtained FAA certification on December 30, 1963. At that time the American company was producing one 269 per working day.

Hughes also developed the model Hughes 300AG, a version of the 269B specially conceived for agricultural use. This model was fitted with two tanks (one on each side for a total of 227 liters of chemicals) and a spray bar with a working width of 10.67 m. Upon request the helicopter could be equipped with a cable cutter.

The American technicians developed for this version a special tail rotor which contributed to a reduction in noise emissions of up to 80%. The Quiet Tail Rotor (QTR) was installed in series from June 1967 onwards. At operators’ request helicopters which left the assembly line before that date could be modified with a retrofit kit.

According to data collected, a total of 461 units of this version were built. Production of the Hughes 269B ceased by the end of the Sixties when the Hughes 269C appeared.

In January 1964 the price of the 269B (standard version) was 29'875 US dollars (actually the equivalent of Sfr. 472'000 - year 2014*) while the cost of the Deluxe version (which included for example Deluxe interior upholstery, side fairings, control opening boots, ash tray and lighter) was offered for 31’500 US $ (Sfr. 497'700)*.

The price for the Hughes 300AG (equipped for spraying application) was 34’795 US $ (Sfr. 550'000)*.

Civil use

The Hughes 269B was mainly used for: flying school, business and private flights, photographic and observation missions. It could also be fitted with a special spray system for agricultural applications (e. g. crop spraying and dusting). Several (American) cities used it in law-enforcement roles. In this function as an "eye in the sky" it was used to patrol designated areas and support police units on the ground. Occasionally this aircraft was also used as an air ambulance.

Nowadays the Hughes 269B still flying are mostly used by private users. However there are some aviation schools which are still offering training courses on this historical helicopter.

Technical description

The Hughes 269B is a lightweight three-seater helicopter of standard configuration. The main rotor has three fully articulated blades; the two-bladed tail rotor is of the teetering type. Its exterior aspect may not appear particularly attractive. Design emphasis is on simplicity in order to keep purchase and operating cost to a minimum. Therefore most of the mechanical elements are exposed and easily replaced in case of necessity.

The Model 269B is powered by a four cylinders Lycoming HIO-360-A1A fuel injected engine producing a maximum take-off power of 134/180 kW/cv at 2'900 up to 3’900 ft. The air-cooled engine is mounted horizontally like in light aircraft.

The Hughes technicians have simplified transmission/rotor engagment by replacing the former manual lever system with an electric clutch servo. The main transmission drive belts are thus tensioned automatically to give a smoother engagment than formerly obtained by direct manual control. This simple solution offers some important advantages like for example the reduction of vibration level and the simplicity of construction.

The fuel tank has a capacity of 95.4 litres (25 USG) and is located behind the right passenger seat.

On the opposite side there is the support for the 72 litres (19 USG) auxiliary fuel tank.

Basic structure

The basic fuselage structure is made of welded steel tubes while the tail rotor is mounted on a one-piece small-diameter aluminium tube sustained by an A frame. The tail rotor shaft is mounted inside the tube.

The forward shift in center of gravity is allowed for by moving the battery back to a suspended cradle beneath the tail boom.

A small fin mounted on the starboard side of the boom directly opposite the tail rotor with about 30 degrees dihedral acts as a stabilizer surface. The dihedral eliminates sudden changes in pitch trim during transition from hover to forward flight. To improve the longitudinal stability the aircraft is fitted with a small triangular vertical stabilizer. The skid landing gear features four oleo-pneumatic shock absorbers which permit soft landings on flat or uneven terrain.

Ground handling can be easily accomplished by two people using two ground handling wheels.

Performance

In standard atmospheric conditions, at its maximum take-off weight of 757 kg (1'670 lbs), the helicopter has a cruising speed of 70 mph (112 km/h), while the never exceed speed at sea level is 87 mph (141 km/h).

Its service ceiling is about 13’000 ft (3’962 meters). In standard day conditions at sea level the initial rate of climb is about 1’540 ft/min (442 m/min).

Under the same flying conditions the helicopter hovers in ground effect at about 7’710 ft (2’350 meters), or 5’300 ft (1’615 meters) out of ground effect.

With an average hourly fuel consumption of 9-10 USG (30-37 litres), its range is about 200 miles (320 km), corresponding to about 3h20’of flight endurance.

Rotor and engine limitations

In flight the rotor rpm must be kept between 400 and 530 while the engine operating speed has to be kept between 2'700 and 2'900 rpm. Max permissible cylinder head temperature is 260°C.

Dimensions and weights

The main rotor of the Hughes 269B has a diameter of 7.71 m (disc rotor area 45 sm – 25ft 3.5in 503 sq ft), while its tail rotor has a diameter of 1.01 m (rotor disc area 0.8 sm – 3ft 4in 8.70 sq ft). The fuselage has a length of 6.78 m (21ft 10¾ in). The height to the top of the rotor hub is 2.40 m (7ft 11in). The landing gear track is 2.0 m (6ft 6 ½ in) while the cabin max width is 1.29 m (4ft 3in). The standard empty weight of the aircraft is about 431 kg (950 lbs), while its MTOW is 757 kg (1'670 lbs).

Allowing for a standard pilot weight (77 kg/170 lbs) and with a fuel and oil reserve for one hour of flight (28 kg/62 lbs) the helicopter has a payload of about 221 kg (487 lbs).

Options and accessories

Hughes developed a wide range of accessories to extend the aircraft’s versatility. The list of the main ones included: amphibious floats, litters, cargo rack, external load sling (272 kg – 600 lbs capacity), agricultural spray kit, 19 US gallons (72 litres) auxiliary fuel tank, dual controls, fire extinguisher, dual luggage case, night flying kit, skid plates, tinted glass, cabin heater.

The Hughes 269B in Switzerland

Four Hughes 269B were registered in Switzerland. The first received the registration HB-XCC (s/n 14-0012 b/y 1965) and entered service in summer 1966 with Rotorcraft SA, a firm based at Geneva airport and managed by American entrepreneur William Powell (Bill) Lear (who manufactured the famous Executive jet Learjet). This machine was mainly used by the local Aero Club for pilots' training. At that time one hour of instruction used to cost Sfr. 318.— (1'071.—)*.

XCC was destroyed in an accident on January 28, 1968. While flying over the “La Dôle” ski resort the inexperienced pilot lost control of the aircraft which subsequently crashed on a ski slope.

However in the subsequent recovery it went completely destroyed after being unhooked for safety reasons by the rescue helicopter from a height of about 200 meters!

The second Hughes 269B entered service almost at the same time but with Eliticino and received the registration HB-XCE. It was assembled and flown to Ticino by Willi Meier, at the time mechanic and pilot at Rotorcraft SA.

Despite its limited performance this aircraft was often used by Siegfried Stangier for the transport of passengers, goods and building materials. The helicopter was equipped with a cargo sling and could carry a suspended load of approx. 150 kg. For this kind of flights Eliticino charged Sfr . 8.—/min (27.—)*, or Sfr. 7.—/min (24.—)* for transfer, passengers, school or photographic flights.

The HB-XCE was repeatedly hired by a German company which used it for spraying applications and eventually decided to buy it. Therefore during 1970 this aircraft was cancelled from the Swiss aircraft register.

HB-XCR ( s/n 127-0346 b/y 1968) was used both by the Aero Club of Geneva to replace HB-XCC and by Trans-Heli. The latter company was founded in 1972 in Nyon by Marcel Gay, a winemaker with a flight passion. Mr. Gay fitted the aircraft with a spray kit and used HB-XCR to spray vineyards.