Hiller UH-12B - History and technical description

Origins and development

Toward the end of September 1950 in Palo Alto (California) Major John Oswald on behalf of the Army Field Forces, officially accepted the delivery of the first Hiller helicopter (s/n 50-1254) to be operated by US armed forces.

The aircraft redesignated YH-23 was transferred to Fort Bragg (North Carolina) for a series of tests conducted in view of its use in the Korean conflict that broke out in June of that year.

The success achieved during the evaluations resulted in a total order of 105 aircraft that received the designation H-23A.

In Patuxent River (Maryland) the US Navy also made its own evaluation of an H-23A and favorably impressed by the qualities of this model ordered 16 for the primary training which were designated Hiller HTE-1.

Except for floor mounted controls (replacing the T-bar directly connected to the swash-plate), the Hiller HTE-1 and H-23A were substantially civilian UH-12A in military colors.

The civilian series of the Hiller 360/UH-12A, once some of the so-called "childhood problems" were resolved, altogether proved to be good helicopters, cheap, versatile and reliable. Their commercial success was also due in part to the fact that their initial sale price of 19'995 USD was lower than that of its direct competitor, namely the Bell 47 which was sold in 1949 at about 23,500 USD (Bell 47D1).

Unfortunately the same cannot be said of the H-23A which arrived in Korea in November 1950.

From the early stages of the conflict that lasted until July 1953, the harsh operating conditions, the overwork due to the continuous flight activity and the overload of the helicopter by military equipment such as for example radio, new flight controls, additional electronic equipment and stretchers, and a relatively light construction soon pointed out the limits of the aircraft used primarily for the transportation of injured soldiers, personnel and reconnaissance flights.

These were essentially the tasks assigned to light helicopters operating in a region characterized by mountainous areas where the air support from the beginning of the conflict turned out to be of relevant importance.

In addition to the problems aforementioned, others soon appeared, such as for example the lack of spare parts and specialized personnel available on site to assist military mechanics, to coordinate supplies and supervise operations.

To try to sort out a part of these difficulties, the number of employees of the American manufacturer in that period grew from just under 100 to over 700, with the arrival of managers and specialized personnel from other large companies such as Convair, which during the World War II mass produced aircraft for the USAAF.

A part of the troubles was attributed to the fact that at the time of the outbreak of the Korean conflict, Hiller had started the series production of helicopters only just one year earlier. The first deliveries of civil helicopters manufactured in series were made in April 1949.

In order to manage this delicate situation and improve the qualities of its helicopter, Palo Alto’s engineers in collaboration with the US Army and US Navy experts at the beginning of 1951 started to redesign the Hiller H-23A and some 50 other major modifications were incorporated. A part of them was suggested by military pilots.

In order to meet the needs of the US armed forces, the production of helicopters (and spare parts) for the civil market took second place. Of course this decision had a heavy impact on civil operators. In that difficult period some of them were forced to close the doors and stop their business.

The first tests of the new Hiller H-23B began in July 1951, while the first test flights took place in September. The first deliveries took place two months later.

In the edition of the famous English magazine Flight International dated November 30, 1951 readers found an article entitled "Helicopters in uniform" where the journalist presented in detail the changes introduced on the model H-23B, and the same did the magazine Aviation week in the edition dated December 3, 1951 with the article "Hiller copter has a new look".

That year, the American manufacturer whose shareholders approved the change in the company's name from United Helicopter Inc. to Hiller Helicopters at the annual shareholder meeting, produced altogether 273 "B Models".

With the outbreak of the war in Korea and supplies for the armed forces, the turnover grew from 557,000 USD in 1949 to 14,399,000 USD in 1952.

By July 1952 the increase in production capacity allowed the American manufacturer to return to dealing with the orders of civilian and foreign military customers. As we will see later in this article among the first to receive the new helicopter there were also the Swiss armed forces.

In the period between 1952 and 1955 (the year of the appearance of the new C version), 453 helicopters of the H-23B/HTE-2/UH-12B series came out of the assembly line.

In September 1953 Hiller Helicopters celebrated the delivery of its 500th helicopter.

The Hiller UH-12B

The long wait of the civil operators was somehow rewarded by the appearance on the market of the UH-12B model resulting from the experience gained on the military model H-23B and 354,000 hours of engineering research, design and testing.

Compared to its predecessors this model incorporated several technical improvements such as for example a more powerful engine, a new transmission, improved robustness and a new skid landing gear with two jockey wheels fitted to facilitate ground handling.

It is significant to note that metal skids were first tested experimentally by the US Coast Guard in 1945.

Pilots preferred this solution that in addition to simplicity of construction and lightness also offered greater stability on the ground, especially in the case of an emergency landing.

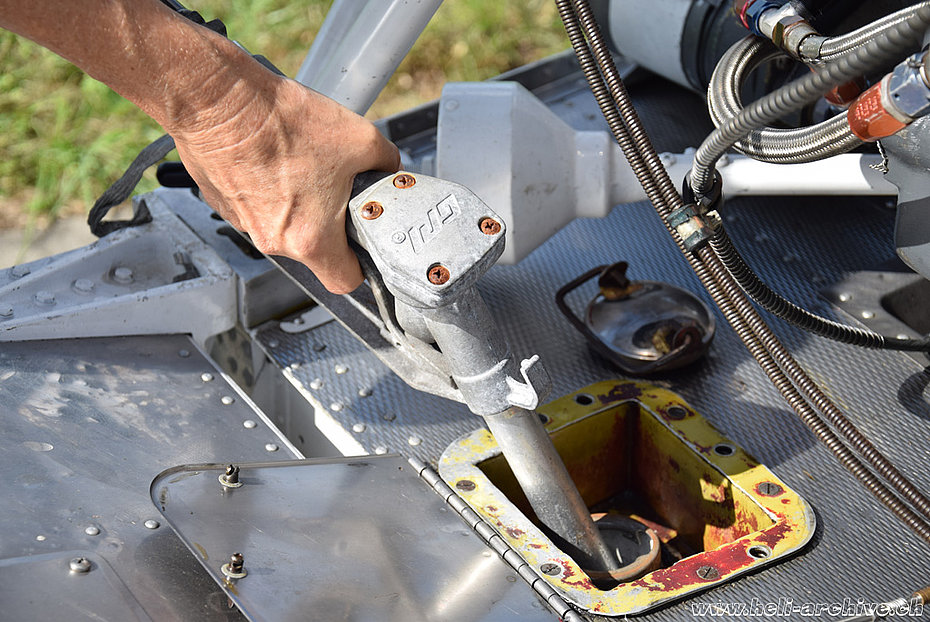

The new flying controls included a new twist-grip throttle on the collective-pitch lever. The improved rotor head incorporated a redesigned collective ballast-weight system to reduce the load on the collective-pitch lever at various settings. This ensured that the lever needed less force to shift it, and an adjustable friction nut allowed it to be set for any flight condition and then disregarded.

The other new device in the control system was fitted to the cyclic-pitch linkage behind the canopy to prevent cyclic vibrations from being transmitted to the stick. The two sprung weights, one applied to fore-and-aft control and the other to lateral, are tuned to the rotor frequency and vibrate themselves when any cyclic oscillations come back from the rotor head. This further refinement reduced stick-shake.

The main rotor system was improved by making provision to add small balance weights to the main-blade tips, and the Rotormatic was fitted with roller bearings and provided with an adjustable-incidence device.

The tail rotor pitch control arm was redesigned to permit interchangeability.

The list of the improvements included the re-location of some engine accessories, such as fuel pumps and oil cooler to provide easy accessibility.

Also the inspection and maintenance of the flight controls below the floor and the instruments mounted on the panel was facilitated thanks to quick release fasteners.

To achieve longer service-life of moving parts the transmission lubrication system was completely revised.

The tail rotor pitch change bearings were modified for the same reason.

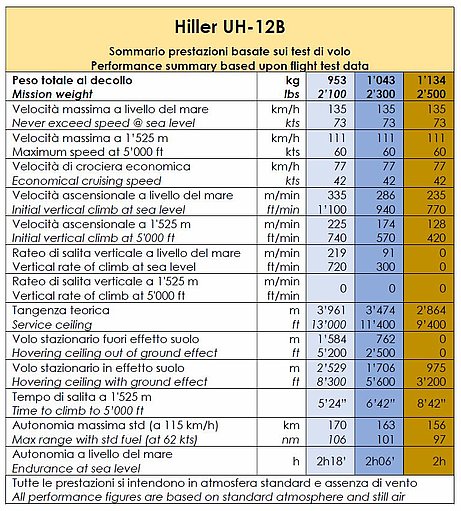

The power available was increased by 16/22 kW/hp, while the empty weight of the helicopter rose from 770 kg (1'698 lbs) to 796 kg (1'756 lbs) (+ 26 kg / 58 lbs), while the payload passed from 318 kg (703 lbs) to 377 kg (744 lbs) (+ 59 kg/129 lbs). The maximum take-off weight was increased from 1,089 kg (2,400) to 1,134 kg (2,500 pounds) (+ 55 kg / 100 pounds) and therefore the rotor disc load was slightly increased.

The Hiller UH-12B received the type certificate 6H2 from the Civil Aeronautics Administration (CAA) on November 2, 1951 while the flight manual was approved on March 27, 1952.

It is undeniable that compared to the original Hiller 360/UH-12A version the Hiller UH-12B incorporated several and appreciated improvements, but the real leap in quality (also in terms of performance) in the production line of this series was made in 1956 with the apparition of the H-23D. This model looked much like the UH-12C, but it was substantially re-engineered, in particular featuring a new Lycoming VO-435-A1C engine. It was delivered only to the armed forces and incorporated the experiences logged over a seven years production period during which some 900 helicopter were manufactured.

When Hiller engineers designed a new transmission for the OH-23D conceived with a time between overhauls of 1'000 hours, the US Army, which at the time was the main operator of this line of helicopters, offered its financial support for its technical development. By way of comparison, previous models needed overhauls every 300 hours of flight. In aviation longer intervals between overhauls will result in lower operating costs.

A few years later Hiller’s engineers developed from the Hiller OH-23D the Hiller UH-12E, which is considered by several civil operators (especially in the US and Canada) as one of the best performing helicopters in its category.

Overall, the US armed forces operated about 1,800 OH-23. The version built in greater number has been the OH-23G/12E (793) powered by a Lycoming VO-540-B1A engine.

According to the information gathered, in August 1953 the Hiller UH-12B with standard equipment was sold for 34,200 USD, approximately 166,500 Swiss Francs. The Bell 47G, Hiller UH-12B’s direct competitor in that period was sold at a higher price (about 38,000 USD - 185,000 Sfr.).

The hourly cost of the helicopter based on the tables provided by the manufacturer ranged from 44.19 USD for 300 hours/year down to 29.95 USD for 600 hours and finally 27.57 for 900 hours use.

Civil employment

Civil operators mainly used the Hiller UH-12B for the transportation of passengers, supplies, mail and building materials, training flights, aerial applications, aerial observation, photographic flights, aerial advertising, and as an aerial ambulance.

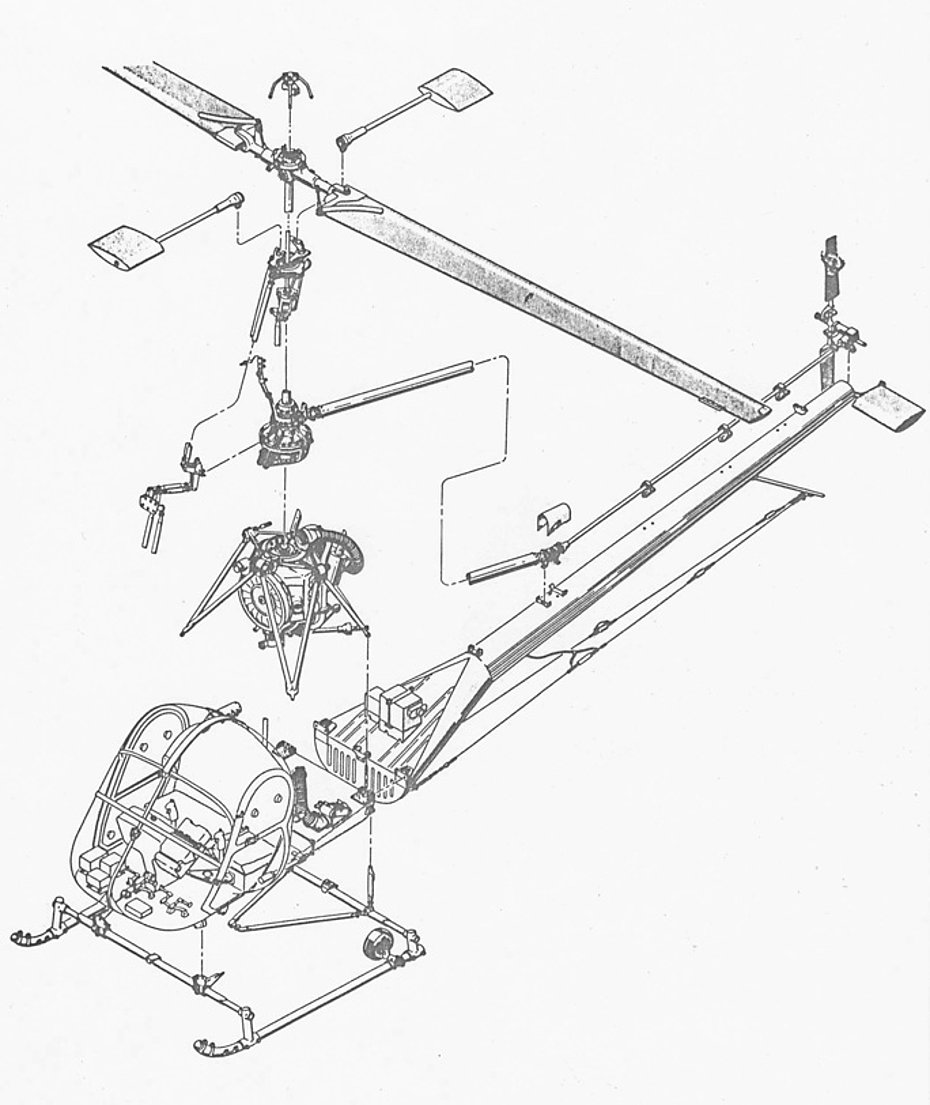

Technical description

The Hiller UH-12B manufactured by Hiller Helicopters in Palo Alto (California) is a three-seater helicopter (occupants are seated side-by-side) of standard configuration.

Originally it was powered by a six-cylinder Franklin 6V4-200-C33 manufactured by Aircooled Motors Inc. (Syracuse. N.Y.). The engine has a maximum output power of 149/200 kW/hp at 3'100 rpm at sea level.

The engine is mounted vertically and is air-cooled by a fan that forces air towards the cylinder heads and the oil cooler. The accessories section includes generator, starter, magnetos, oil and fuel pumps and a tachometer that allows the pilot to monitor the rotor rpm through the special dual needles instrument on the instrument panel.

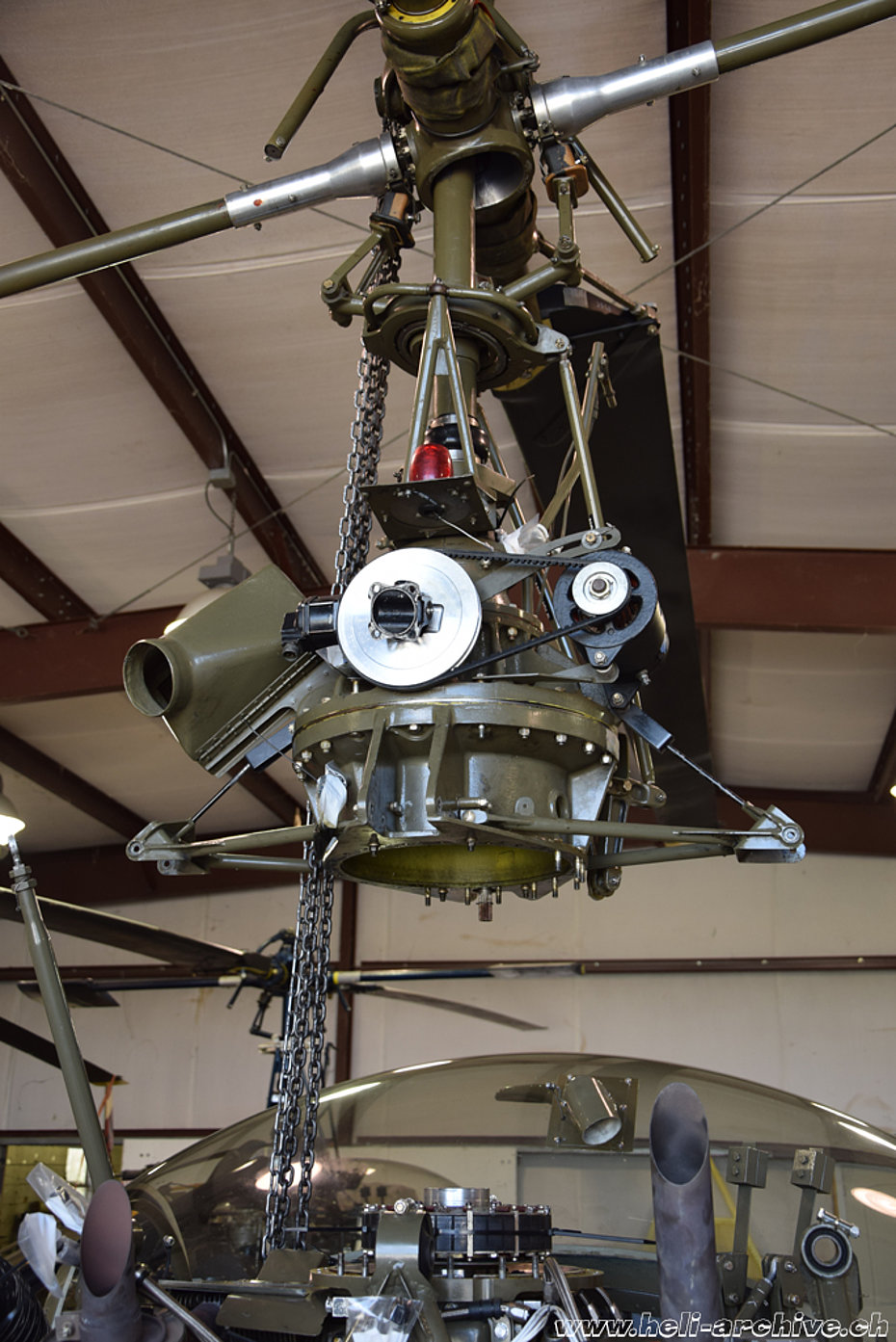

The engine and the transmission form a single unit fixed to the structure by a castle built with steel tubes arranged in a reversed "v".

The main transmission is installed directly on top of the engine through a simple drive system. The transmission drives the engine cooling fan, main and tail rotors and the main rotor tachometer. The transmission consists of an upper section, center section and a lower section. An automatic centrifugal mercury clutch is provided to reduce the loads imposed upon the engine during engine starting. Engagement of the clutch begins at approximately 600 rpm with positive engagement at approximately 1,450 rpm.

The Borg-Warner one way clutch, developed through an extensive test program with the military, connects the planetary gear system of the transmission to the main rotor drive shaft. This clutch allows the rotor to rotate freely during autorotation in order to perform safe emergency landing with the engine in idle or off.

The speed ratio of the engine to the main rotor in 9.17 to 1, and the engine to the tail rotor 1.59 to 1.

Flexible push-pull controls are used to control engine functioning (gas, starter, mixture fuel pump and carburetor).

The 106 litres (28 USG) bladder type fuel tank is located below the engine deck at the center of gravity.

The average fuel consumption (the engine uses 100LL gasoline) is of about 60 litres/hour (15.6 USG).

The oil system with a capacity of 9.4 litres (10 quarts) contained in a cast magnesium alloy tank is used for transmission and engine lubrification. An engine driven oil pump delivers oil to the oil cooler from the engine sump. From the air cooler, part of the oil enters the engine and the remainder is directed upward to the transmission. By gravity oil passes through the transmission and engine and then to the engine sump. Adequate oil temperatures and pressure are monitored by the pilot on the instrument panel.

Basic body structure and tail boom are of semi-monocoque metal stressed-skin construction. The upper surface of the structure in the area of the engine compartment incorporates a stainless steel deck as a firewall. A corrugated retaining structure for the bladder type fuel cell is built into the structure below the engine compartment. Provisions have been made for venting the compartment under the seat and the engine deck.

Cabin enclosure is a composite structure of aluminum alloy and Plexiglas in the nose, canopy and door which assure an adequate visual in all direction.

Canopy and windshield are in sections, permitting replacements as separate units. The aft bulkhead of the cabin enclosure is constructed with corrugated stainless steel sheet acting as a firewall between the cabin and the engine compartment.

The helicopter is equipped with a skid landing gear of tubular construction. A dolly wheel is incorporated with each skid to facilitate ground handling.

The UH-12B is fitted with Hiller's "Rotor-Matic" the original control system herewith shortly described. The servo rotor is connected directly through universally-mounted transfer bearings and simple linkage to the pilot's cyclic stick. Movement of the cyclic introduces to the servo rotor “paddles” positive or negative pitch changes and aerodynamic forces thus developed tilt the rotor head and produce the effect of cyclic pitch changes to the rotor blades.

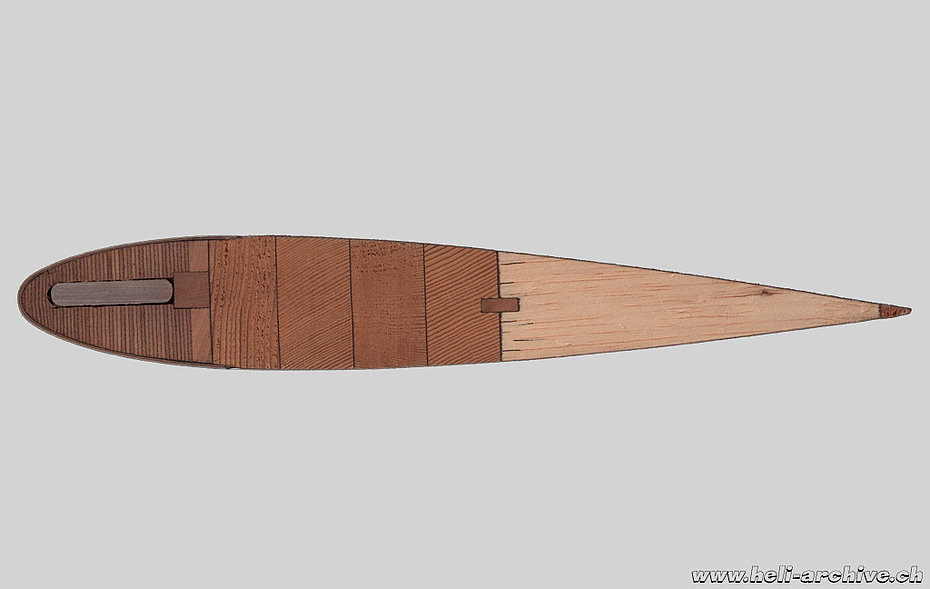

The main rotor blades were manufactured by Parson Industries Inc.

The blades are reinforced at the root by metal plates, screwed, bolted and cyclic welded to the wood. A fixed trim tab is attached to each blade. Each blade tip has provision for static balance.

The main rotor hub is of forged aluminum alloy construction with steel inserts to support the rotor fork bearing.

The rotor blades are attached to the hub by means of a forged steel blade fork and a tension-torsion bar made of 43 laminations of high quality stainless steel.

The tail rotor blade is of aluminum alloy monocoque construction and attached to the hub by means of a tension-torsion bar. The tail rotor hub is of steel construction and provides a flapping hinge for the blades.

A fixed horizontal stabilizer gives additional longitudinal stability in forward flight. It is constructed of a steel tubular spar with aluminum alloy ribs and skin.

The main rotor flight controls (collective and cyclic) are of a push-pull tube and bellcrank design, while tail rotor is accomplished through a cable and bellcrank system. Push-pull tubes and torque tubes in the main rotor flight controls are fabricated from SAE 4130 seamless steel tubing, while bellcranks are all 256-T6 aluminum alloy.

An electrically-operated trim system is incorporated with the cyclic control stick installation to provide longitudinal and lateral trim. Trim mechanism are individual installations each consisting of a spring-loaded cylinder and an electric actuator. The trim system counteracts unbalanced conditions by applying a mechanical force to the cyclic controls so that desired flight attitudes may be maintained with the stick.

The helicopter is equipped with a 28V DC electrical system. Power being supplied by either a storage battery or the engine driven generator. The 24V battery is mounted on the tail boom transition section. The generator is mounted on the lower accessory section of the engine. An external power receptacle is provided on the aft of the side of the fire wall.

Dimensions, masses and payload

The Hiller UH-12B has a main rotor with a diameter of 10.75 m, while the tail rotor has a diameter of 1.68 m. The fuselage has a length of 8.50 m. The maximum height is 3.00 m. The landing gear has a track width of 2.30 m.

The empty weight of the helicopter is about 751 kg (1,656 lb), while the maximum take-off weight is 1,134 kg (2,500 lb). The payload is therefore around 383 kg (844 lb).

Optional equipment list

The list of the optional equipment offered to increase the versatility of the Hiller UH-12B included: two external stretchers, floats for amphibian use, auxiliary fuel tanks (2 x 72 litres – 19 USG), radio, agricultural kit for liquid and powder products, external load sling with a maximum capacity of 200 kg (440 lbs), turbocharger, heating and defrosting system, lighting system, megaphone.

The Hiller UH-12B in Switzerland

The Hiller UH-12B made its first appearance in Switzerland in October 1952, when the army received the first aircraft designated KAB-201 (Kampffeld- und Artillerie-Beobachtung - artillery and battlefield observation) followed shortly thereafter by a second model (KAB-202).

These aircraft were the first helicopters to serve with the Swiss armed forces. The ordering and importing was most likely managed by Air Import of Lucerne. This company was the first to operated helicopters in Switzerland and acted as the official Swiss representative on behalf of the American manufacturer. Since almost all the production at that time was destined to the US armed forces, it is reasonable to think that the wait for the delivery was quite long.

On December 19, 1952 at Davos, KAB-202 piloted by Josef "Sepp" Bauer took part to an exercise with avalanche dogs organized by the Swiss Air Rescue Guard (SARG - founded in April that same year) in collaboration with the Swiss Alpine Club.

In August 1953 the Swiss company Bührle & Co. ordered a Hiller UH-12B (s/n 587) which arrived in Switzerland at the beginning of January 1954 and received the call sign HB-XAC.

This helicopter was usually piloted by Oswald Matti and used to transport personnel and occasionally equipment on behalf of the company. Sometimes it was also used for commercial services as well as aerial ambulance on behalf of SARG.

In 1956 it was sold to the Swiss army as KAB-203 and replaced by the better performing Agusta-Bell 47G2 HB-XAP.

The Hiller UH-12B on the Jungfraujoch

The year of glory for this helicopter in Switzerland has been without doubts 1955. In March, Sepp Bauer at the controls of Air Import’s Hiller HB-XAH (s/n 686) made several exploits showing his skills as a helicopter pilot.

Despite the limited performance of the helicopter on March 2nd he accomplished an exceptional exploit landing on the Jungfraujoch at an altitude of 3'450 meters (11’320 ft).

This historical feat attracted the attention of the international press but lasted only a few months.

On June 6, 1955 the French pilot Jean Moine accompanied by the alpine guide André Contamine at the controls of the Bell 47G2 F-BHGJ landed on the top of Mont Blanc at 4'807 meters (15,775 ft)! In practice the Hiller UH-12B showed its operational limits at much lower altitudes.

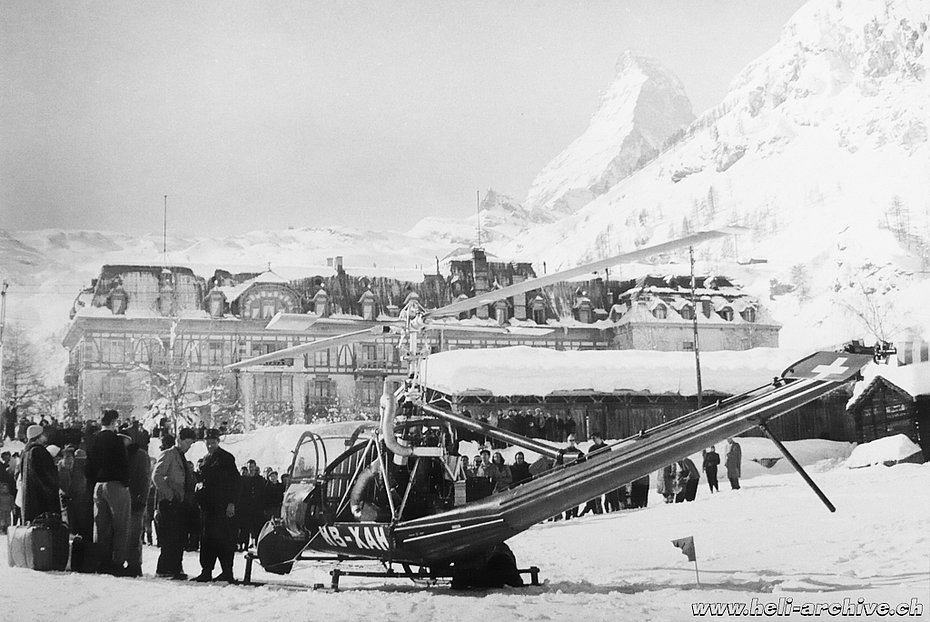

In February 1955, due to heavy snowfall, the alpine village of Zermatt remained isolated. The famous glaciers pilot Hermann Geiger with his Piper PA-18 Super Cub HB-OED and Sepp Bauer with the Hiller UH-12B HB-XAH carried out various shuttle flights to supply the village and descend the (rich) tourists stuck in the famous tourist resort. With two passengers on board Sepp Bauer had to use all his skills to take off from the improvised airfield located at about 1'600 meters (5,250 ft) above sea level.

On the following March 26, the same pilot executed one of the first aerial assembly in Switzerland, placing a weathercock on the top of Wollishofen’s church tower near Zurich. The same helicopter was again used to set in position a lighted sign.

Between March 25 and 27, the SARG organized a demonstration in Zurich during which the various rescue techniques were shown. According to the press articles altogether around 350,000 watched the practical exercise.

Oswald Matti and Sepp Bauer took part to the exercise piloting the Hiller UH-12B HB-XAC respectively the HB-XAH.

On that occasion some experimental equipment such as for example the net suspended under the helicopter for water rescues, the Akja stretcher and the descender known as "Liberator" were used.

In the course of 1955 HB-XAH was equipped with a spray equipment and operated in Holland to spray crops.

That year another Hiller UH-12B received the Swiss civil registration HB-XAN for a very short time.

The helicopter concerned was the first purchased in May 1955 by the Bundesgrenzschutz (BGS), the German Federal Border Guard. For the record it must be remembered that in Germany, at the end of WW2, following the agreements of the Allied armed forces signed in Paris, all aerial activities with powered aircraft were banned for a period of 10 years.

The only two helicopter companies then existing in Switzerland, namely Air Import SA and Schweizerische Helikopter AG (Heliswiss) taking advantage of the ban imposed by the Allies obtained special permissions to carry out commercial services (like for example advertising flights, photographic flights, aerial applications) with their helicopters.

In order to gain time the BGS decided to temporarily register its helicopter in the Swiss civil register. The HB-XAN after the transfer flight Cormeille-en-Vexin/France – Basel/Switzerland reached its new base in Bonn-Hangelar. The German helicopter pilot Eck Bender who had been trained in Switzerland by Air Import was at the controls of the helicopter. The latter then received its new call-sign D-HABA.

By January 1, 1957 Air Import was incorporated into Heliswiss and towards the end of the year HB-XAH was sold to Bristow Helicopters Limited and used mainly for flight training.

Heliswiss preferred to standardize its fleet choosing the new (Agusta-)Bell 47G2 that performed better than the Hiller UH-12B.

The last Hiller UH-12B to fly to Switzerland has been almost certainly F-BIFS (s/n 249) which took part at the airshow in Bex/VD in 1985.

This helicopter was one of the last to fly in Europe. After being used to train military pilots in France it was sold to a civilian operator. In 2006 it was sold again to a new owner and based in Tournon in the region of Albertville/F and received the call sign F-AYFS.

Unfortunately, on March 14, 2018 shortly after the take-off from the village of Saint-Jorioz, the 52-years-old pilot, due probably to a sudden loss of power, was forced to ditch in the waters of the lake of Annecy, not far from the shore. Fortunately neither him nor his 93-year-old passenger reported injuries but the helicopter has been seriously damaged.

The Hiller UH-12 in flight

Autumn 2015 – Finally, after the bureaucratic process to get permission to follow a piloting course in the United States, one of my dreams is going to be realized: I am at the heliport of Dove, near Sarasota in the State of Florida. Waiting for me is flight instructor Joanna Gollin, owner of Joannair Inc., and on the helipad stand her Hiller UH-12C N103JA (s/n 782, c/y 1956), a machine with flight characteristics very similar to the UH-12B.

What distinguishes this version from the previous one is the one piece rounded canopy made of Plexiglas that offers a better visual especially downward. Other improvements concern the redesigned instrument panel about one third smaller and a new carburetor that reduces the pilot's work by automatically adjusting the gasoline-to-air mixture depending on the altitude.

After the pleasantries and after having checked that all the documentation is in order finally we can start the first piloting lesson. Despite its almost sixty years of age, the helicopter is in excellent conditions, merit not only of the enthusiastic owner but also of the mechanics of United Helicopter Inc., a company specialized in the reconstruction and maintenance of Hiller models UH-12B and C based at Dove’s heliport.

After the pre-flight inspection Joanna tells me to take place in the helicopter and I install myself in the center. Getting on this helicopter is quite easy because the height from the ground is reduced, the seat is comfortable and the cabin space sufficient for three occupants of normal build. For greater comfort the pedal’s position can be shifted by mean of a pin.

After Joanna took place next to me occupying the left seat we follow the check-list: master switch ON, fuel reserve OK, shut off valve FUEL ON, fuel auxiliary pump ON, then OFF (warning light ON), switch OFF, mixture on RICH, carburetor lever on COLD, air filter on FILTER, collective pitch down, slight opening of throttle, magnetos on BOTH and we are ready to start the engine. Joanna lowers the lever which through a cable activates the starter. The 157/210 kW/hp Franklin 6V4 335B engine starts after a few seconds by emitting a spit of white smoke and immediately the rotor accelerates. Since today it is quite hot we fly without the doors, but even so the noise level in the cabin is acceptable.

After a few minutes in idle at 1,700 rpm the temperatures and pressures are within the green arc. We increase the throttle up to 3,100 rpm and then proceed with the check of the magnetos, the free-wheel and the generator and we are ready for take-off.

Joanna tells me to follow her in the movements and after gently lifting the helicopter she positions the aircraft in the center of the heliport. I am ready and, I confess, also excited. We proceed with the first exercises in hoovering flight "to feel the controls". These are not servo-assisted so it takes some force to operate them, and the reaction time is a slightly delayed. "It's normal" tells me Joanna "it’s a characteristic of this helicopter, it has its times, you'll get used soon". On the cyclic (the stick is short and seemingly off-axis) there is the electric trim that fortunately relieves my physical effort. The helicopter is nice to fly, although in my opinion the force necessary to action the flying controls requires a bit more muscular force compared to my expectations, on the other hand the stability is remarkable. In cruise flight, wishing it is possible to fly hands-off. The roar of the Franklin engine is reassuring, and the power available is comparable to that of the Schweizer 300C that I used for my flight training in Switzerland.

Beware of speed

Today the wind in Dove blows regular at about 15 knots (28 km/h), something anything but rare here since the heliport is not far from the sea. Joanna explains to me that according to the flight manual the helicopter is controllable with winds up to 20 knots independently from the direction.

However it is necessary to pay attention especially during the 360° turns on the spot.

"Let's take a ride around the corner" tells me Joanna. After a check of the instruments we are ready to take-off for the first circuit. The motor rpm are stabilized at 3,100 rpm: we take a little speed and stabilize at 43 knots to get the best rate of climb. Aided by the upwind we quickly reach 213 meters (700 feet) from the ground, which is the upper limit of airspace Golf here in the United States, the airspace not controlled by traffic controllers. The visual from my seat is good in all directions.

Before passing on downwind Joanna imposes me to not exceed 50 knots (92.5 km/h). The reason is simple: the VNE on this helicopter is only 73 knots (135 km/h)! A plate in the cabin warns the pilot that from 2,000 feet of altitude (610 meters) speed must be reduced by 2 knots (about 4 km/h) every 1,000 feet of climb (305 meters). In calm wind the best cruising speed is 60 knots (110 km/h).

As said the helicopter in flight is very stable and the vibration level acceptable. The classic woop woop woop of the two blade rotor is perceptible on the cyclic control. The helicopter I am flying has wooden blades and from time to time it is necessary to make adjustments (balance and tracking).

The approach, carried out at reduced power, is accomplished by monitoring the carburetor’s air temperature instrument. The danger of freezing in certain situations is very high (the yellow arc warns us) and if this happens the engine could, at worst, even shut off. Before this happens it is necessary to operate the "CARBURETOR HEATING" lever positioned between the legs on the ON position. In this way we let hot air flow to the carburetor without any risk. Before landing, after having restored full power, the lever is repositioned to the "OFF" position.

After some circuits Joanna proposes to carry out the first autorotation. Therefore I line up to the flying field and after completely lowering the collective she closes the throttle and I observe the splitting of the two needles MOTOR/ROTOR. Simultaneously I slightly pull backwards the cyclic and I correct the yaw with the right pedal. The descent in autorotation is carried out at a speed between 45 and 55 knots. I observe the rotor rpm remaining within the green arc; the rotor inertia is good. At about 50-65 ft (15-20 meters) above the ground I gently start with the flare and the rotor's rpm rise to the upper limit of the green arc (360 rpm). At about 10 ft (3 meters) from the ground I level the helicopter and I pull up the collective. For safety reasons the instructor re-opens the throttle and I immediately correct applying left pedal. The Franklin engine that during the descent felt "mumbling" responds immediately. In the landing phase I hear the feedback of the forces acting on the rotor through the cyclic. If landing in the grass is not a great problem, on a hard surface things change. It takes some time before one gets used to the reaction times. The experience does the rest.

Within a few hours I get used to the controls and I maneuver the helicopter with the necessary safety and precision and I start to enjoy the fantastic landscape that surrounds me. There are many small ponds and so it is natural to ask Joanna if there are also crocodiles. "There may be crocodiles and snakes, so let's not end up in the middle of a pond" and laugh.

After five hours of flight training she tells me that she would not have objections letting me fly alone with her helicopter and writes a note on this regard on my flight book: what a great satisfaction, and what a nice experience. It is a pity that there are no more helicopters of this type in Switzerland!

Over three million hours of flight training

According to the information gathered, it appears that 95% of the young helicopter pilots employed in Vietnam (the average age was about 20 years) followed the basic training at Fort Wolters, a town located a hundred km west of Dallas (Texas). In this school that remained active from July 1, 1956 until August 16, 1973 were trained pilots of the armed forces of the United States (Army, Navy, Marine Corps, Air Force, Coast Guard) and also many South-Vietnamese helicopter pilots.

In the 17 years of operations at Fort Wolters, about 41,000 chopper pilots were trained and 5,600,000 hours of instruction were logged (of which 1 million in 1969).

Between 1956 (year in which 120 Hiller OH-23 were in service) and 1973, the Hiller fleet used at Fort Wolters for the primary training of pilots logged over three million hours of flight training.

In 1968-1969, the period of major activity, in this base were formed an average of 575 helicopter pilots per month and carried out monthly over 85,000 hours of flight using a fleet of more than 1'200 helicopters!

For the primary flight training in addition to the Hiller OH-23 Raven (the number of those employed arrived at about 600 units) were employed the Hughes TH-55A Osage and the Bell OH-13 Sioux.

The cadets started with a basic training course extended over an 8 week period with civilian instructors. The course was divided into the “Pre-solo” phase (4 weeks) and the “Primary I”. Altogether during this period they logged 50 hours of flight and learned how to fly a helicopter.

Then during the next phase (“Primary II”) also of 8 weeks duration they learned from military instructors how to use the helicopter adding 60 hours of flight to their log book. During this course students practiced advanced flight maneuvers such as for example maximum performance takeoff, ground reconnaissance, slope landing and take-off, pinnacle operations, running and rolling takeoff, quick stops, steep approach, maneuvers in small clearings typically surrounded by trees and boulders and of course emergency maneuvers.

With a flight experience of 110 hours under their belts of flight (60 hours solo, 50 hours dual controls), pilots were sent to Fort Rucker (Alabama) where they accumulated another 100 hours of flight (25 hours solo, 75 dual control).

At Fort Rucker pilots did the basic and the advanced instrument training course on the link trainer simulator and on the Bell TH-13T, night flying, flight tactics and then learned to fly larger helicopters such as for example the Sikorsky H-19 Chickasaw, H-34 Choctaw, CH-37 Mojave, Piasecki H-21 Shawnee. Much later new models powered by turboshaft such as for example as the famous Bell UH-1 Huey, the Hughes OH-6 Cayuse and the Bell OH-58 Kiowa, Kaman SH-2 Seasprite, Sikorsky CH-3 Sea King, Boeing-Vertol C-46 Sea Knight made their appearance and were used during the Vietnam war, frequently nicknamed “The helicopter war”.

The entire process from boot camp to Wolters through graduation from Fort Rucker usually required less than a year.

Did you know that...

The great stability of the Hiller helicopters was eloquently demonstrated on several occasions. In January 1949 Stanley Hiller and Lang Washburn after wearing a parachute and heavy winter clothes took off aboard a Hiller 360 to take a promotional photograph. Above the bay of San Francisco the two, after unloosing their seatbelt, came out of the cockpit to cling to the sides of the helicopter near the center of gravity. The image aroused great amazement in the world of the rotary-wing. No other helicopter at that time was able to emulate this incredible performance.

In 1951 pilots George Brockaway and Jim Maede after taking-off from San Francisco decided to see how long they could fly hands-off. The helicopter (a Hiller H-23A) was trimmed for cruise flight at a speed of 60 miles per hour. For the next two hours the pilots did not touch the flying controls!

Recommended readings

The story of rotary-wing pioneer Stanley Hiller and his helicopters is narrated in detail in the book “Vertical Challenge: The Hiller Aircraft Story” written by Jay P. Spencer, University of Washington Press, 1992, a volume that I recommend to read to all rotary-wing fans.

HAB 11/2018